Spicy strips and preparation method thereof

A technology for spicy strips and highland barley flour, applied in the field of spicy strips and their preparation, can solve the problems of high oil content, unfavorable health of consumers, excessive additive content, etc., and achieves the advantages of reducing fat content, avoiding adding preservatives, and reducing dosage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

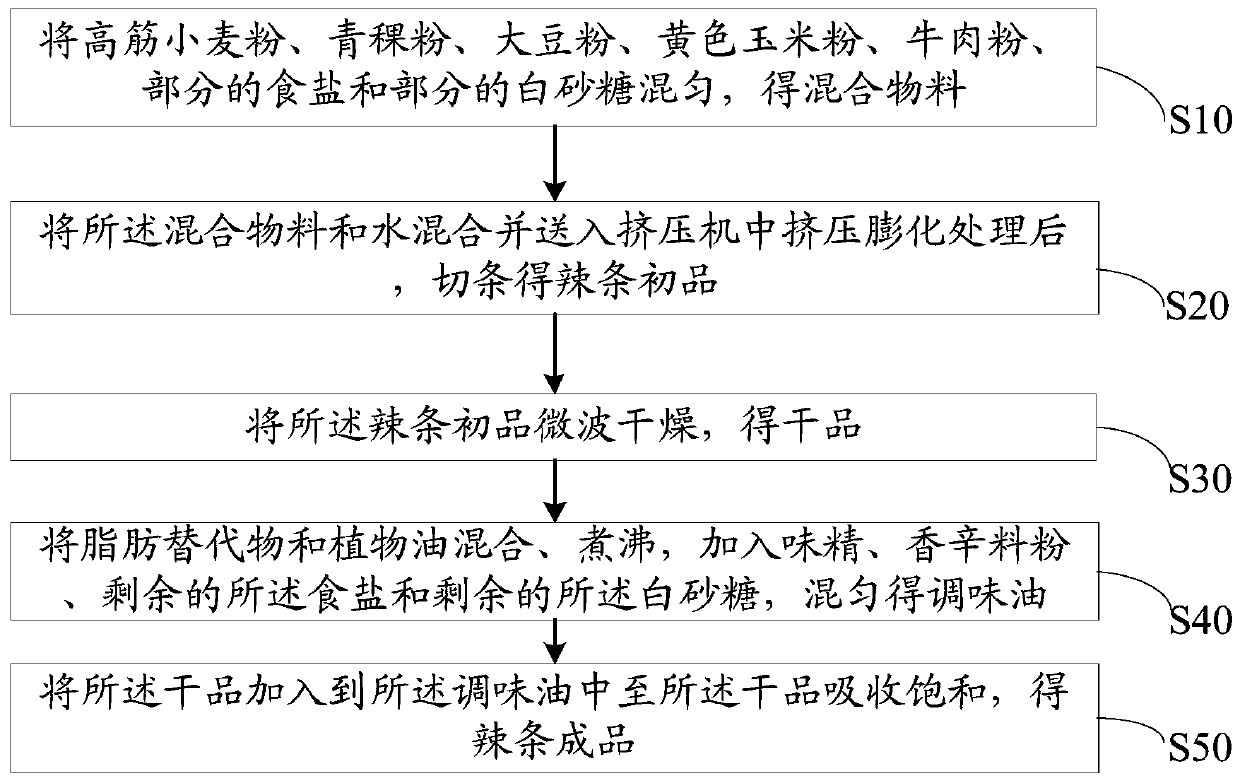

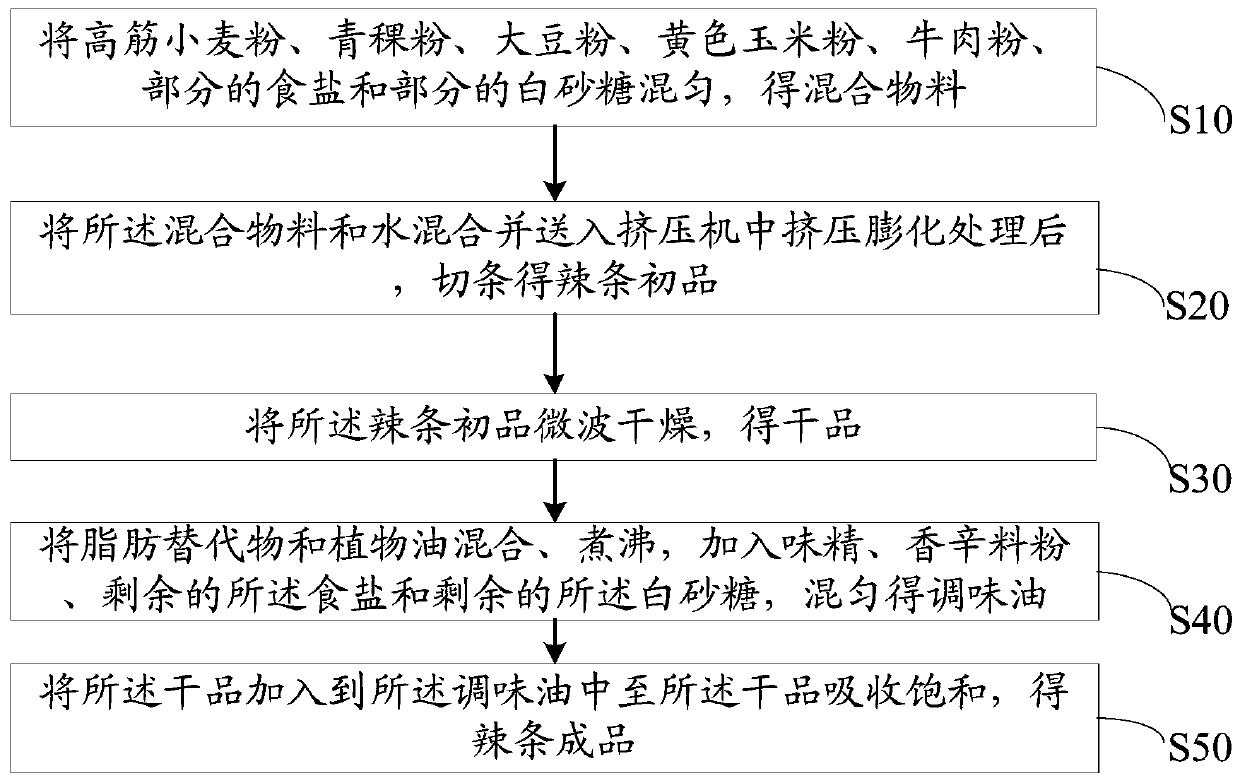

[0038] The present invention also proposes a method for preparing spicy strips as described above, combining figure 1 The schematic flow chart of an embodiment of the preparation method of the shown spicy strips, in this embodiment, the preparation method of the spicy strips comprises the following steps:

[0039] Step S10, mixing high-gluten wheat flour, highland barley flour, soybean flour, yellow corn flour, beef flour, part of salt and part of white sugar to obtain a mixed material.

[0040] Step S20, mixing the mixed material with water and sending it into an extruder for extruding and puffing, and then cutting into strips to obtain the primary spicy strips.

[0041] The existing method of preparing spicy strips is usually to mix the mixed material with water, make dough, and then bake it into dry spicy strips. The spicy strips produced by this preparation method are usually more flexible in taste, and in this embodiment , have adopted the highland barley powder that weigh...

Embodiment 1

[0056] The highland barley flour (the content of β-glucan in the highland barley flour is 5wt%) is pulverized, passed through a 80-mesh sieve, and set aside; the yellow corn flour is pulverized, passed through a 100-mesh sieve, set aside.

[0057] Mix high-gluten wheat flour, highland barley flour, soybean flour, yellow corn flour, beef flour, part of salt and part of white sugar to obtain a mixed material.

[0058] The mixed material and water are mixed and sent into the extruder for extruding and puffing, and then cut into strips to obtain the first product of spicy strips. The process parameters of the extruder are that the solid feeding speed is 10kg / h, and the feeding screw speed is 70r / h. min, the screw speed of the extruder is 100r / min, and the temperatures of the extrusion and puffing zones 1 to 5 are 110°C, 150°C, 180°C, 200°C, and 160°C in sequence.

[0059] The primary spicy strips were microwave-dried at 110° C. with a microwave drying frequency of 300 MHz to obtai...

Embodiment 2

[0063] The highland barley flour (the content of β-glucan in the highland barley flour is 8wt%) is pulverized, passed through a 80-mesh sieve, and set aside; the yellow corn flour is pulverized, passed through a 100-mesh sieve, set aside.

[0064] Mix high-gluten wheat flour, highland barley flour, soybean flour, yellow corn flour, beef flour, part of salt and part of white sugar to obtain a mixed material.

[0065] The mixed material and water are mixed and sent into the extruder for extruding and puffing, and then cut into strips to obtain the first product of spicy strips. The process parameters of the extruder are that the solid feeding speed is 10kg / h, and the feeding screw speed is 60r / h. min, the screw speed of the extruder is 98r / min, and the temperatures of the extrusion and puffing zones 1 to 5 are 120°C, 155°C, 190°C, 210°C, and 165°C in sequence.

[0066] The primary spicy strips were microwave-dried at 110° C. with a microwave drying frequency of 300 GHz to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com