Telescopic WEDM wire-cutting module and control system and control method thereof

A wire electric discharge and wire cutting technology, which is applied in the direction of electrode manufacturing, manufacturing tools, electric processing equipment, etc., can solve the problems of heavy weight, complex structure, and large volume, and achieve the effects of light weight, wide applicability, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

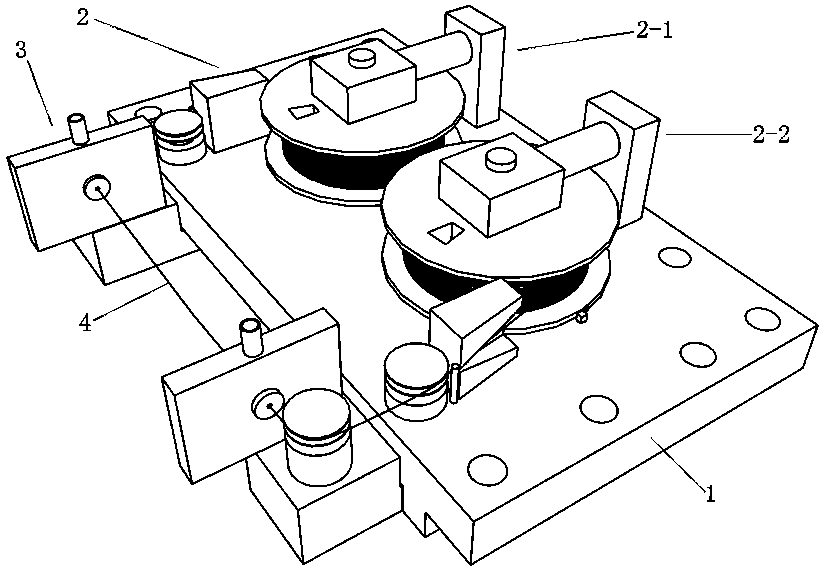

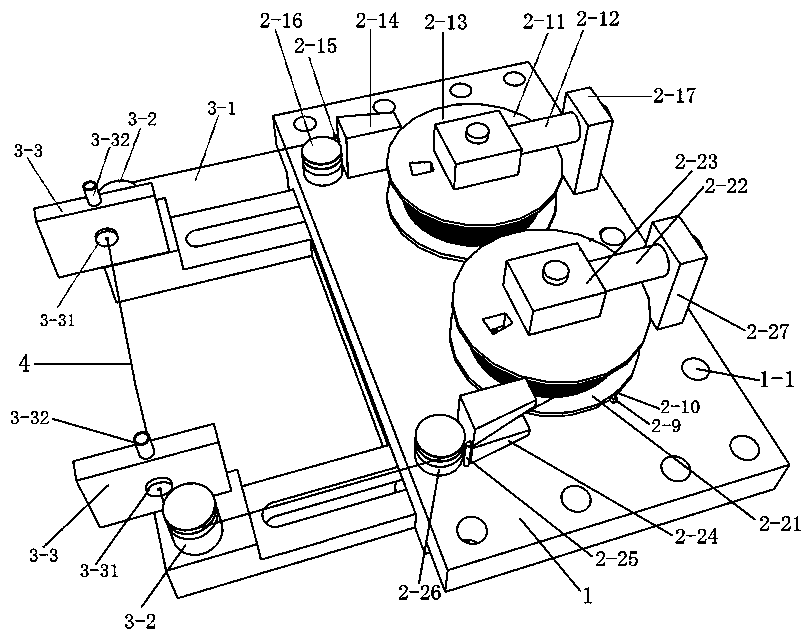

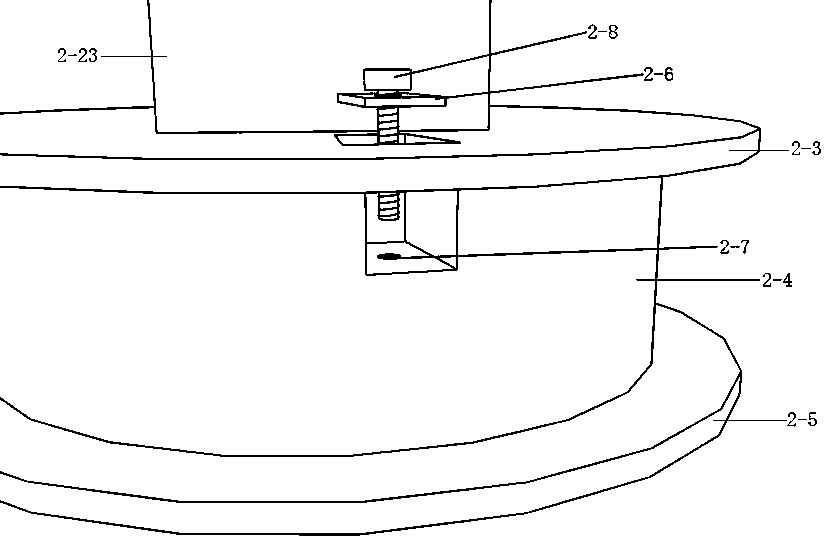

[0038] Such as Figure 1-4 As shown, a scalable wire electric discharge module of the present invention includes a base plate 1, a wire cutting wire tension adjustment module 2, a wire cutting wire telescopic adjustment module 3 and a wire cutting wire 4, and a wire cutting wire tension adjustment module 2 Including the upper tension adjustment module 2-1 and the lower tension adjustment module 2-2, the upper tension adjustment module 2-1 and the lower tension adjustment module 2-2 are symmetrically installed on the left and right ends of the upper plate surface of the bottom plate 1, and the two ends of the wire cutting wire 4 The ends are respectively fixed on the upper tension adjustment module 2-1 and the lower tension adjustment module 2-2. The telescopic adjustment module 3 of the wire cutting wire includes a "]" type slide plate 3-1, which is symmetrically installed on the "]" type slide plate 3-1. The front wire cutting guide wheel assembly 3-2 and the wire cutting wat...

specific Embodiment 2

[0051] Such as Figure 8 As shown, the control system of the scalable wire electric discharge cutting wire module includes a first switch 5, a second switch 6, a third switch 7, a fourth switch 8, a fifth switch 9, a sixth switch 10, an adjustable resistor 11. First relay 12, second relay 13, upper DC motor controller 14, lower DC motor controller 15, display 16, buzzer 17, main control device 18 and power supply device (not shown), adjustable resistance 11 The upper DC motor 2-12 is electrically connected through the first relay 12 or the lower DC motor 2-22 is electrically connected through the second relay 13, and the upper DC motor controller 14 is connected with the upper DC motor 2-12 through the first relay 12 , the lower DC motor controller 15 is connected to the lower DC motor 2-22 through the second relay 13, and the upper DC motor controller 14 and the lower DC motor controller 15 respectively control the upper DC motor 2-12 and the lower DC motor 2-22 to drive the ...

specific Embodiment 3

[0056] refer to Figure 9 , the wire changing method of wire cutting wire 4, the steps are: start the main control device 18, press the third switch 7 and the fourth switch 8, the main control device 1 controls the upper DC motor controller 14 to drive the upper DC motor 2-12 to drive The upper wire wheel 2-11 rotates counterclockwise, and the lower DC motor controller 15 drives the lower DC motor 2-22 to drive the lower wire wheel 2-21 to rotate clockwise. Release on the column 2-4, rotate the wire end to tighten the bolt 2-8 to loosen the fixation of the wire cutting wire 4, and then remove the waste wire cutting wire 4, press the second switch 6, and the main control device 1 pair The number of coils of the two wire wheels stored is reset to zero, and the head end of the new wire cutting wire 4 is inserted into the fixing hole 2-7 through the slot hole of the upper wire wheel 2-11, and the tightening bolt 2-7 at the screw end of the wire is tightened. 8. The wire cutting w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com