Waste acid recovery method and waste acid recovery device used for treating rolled steel pickling waste liquor

A technology for pickling waste liquid and acid recovery, which is applied in chlorine/hydrogen chloride purification, ferric halide, chlorine/hydrogen chloride, etc. It can solve problems such as difficult sludge disposal, secondary pollution, and difficult control, and achieve environmental protection problems and high efficiency Significant effects of recycling and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

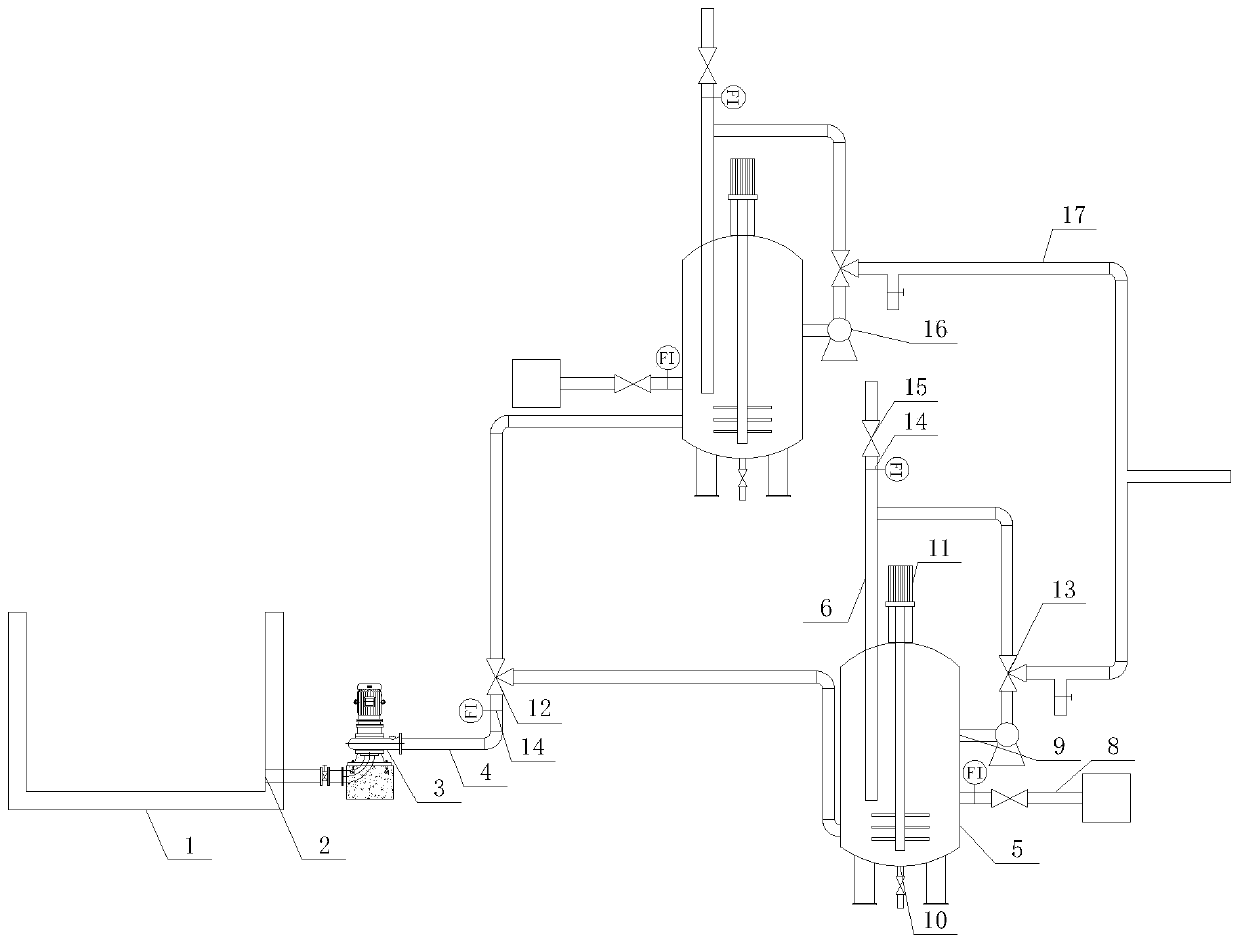

[0033] This embodiment relates to a recovery and treatment method for treating steel pickling waste liquid.

Embodiment 11

[0035] A waste acid recovery method for treating steel pickling waste liquid, comprising the following steps:

[0036] a. Collect the pickling waste liquid obtained by cleaning steel with hydrochloric acid in the acid liquid collection tank, and put 1 ton of pickling waste liquid in a 2-ton closed reaction kettle through a lift pump;

[0037] b. Before introducing HCl gas, add 66kg of water to the reactor at one time;

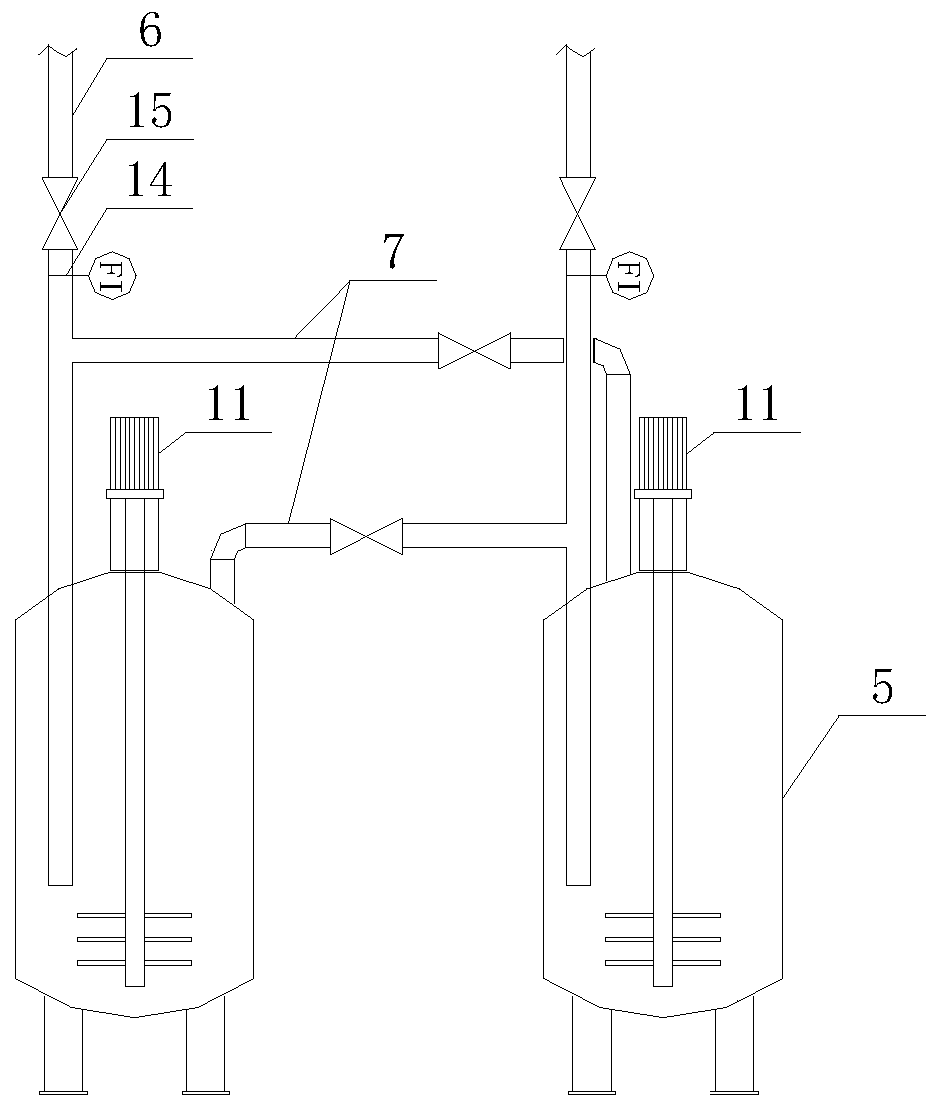

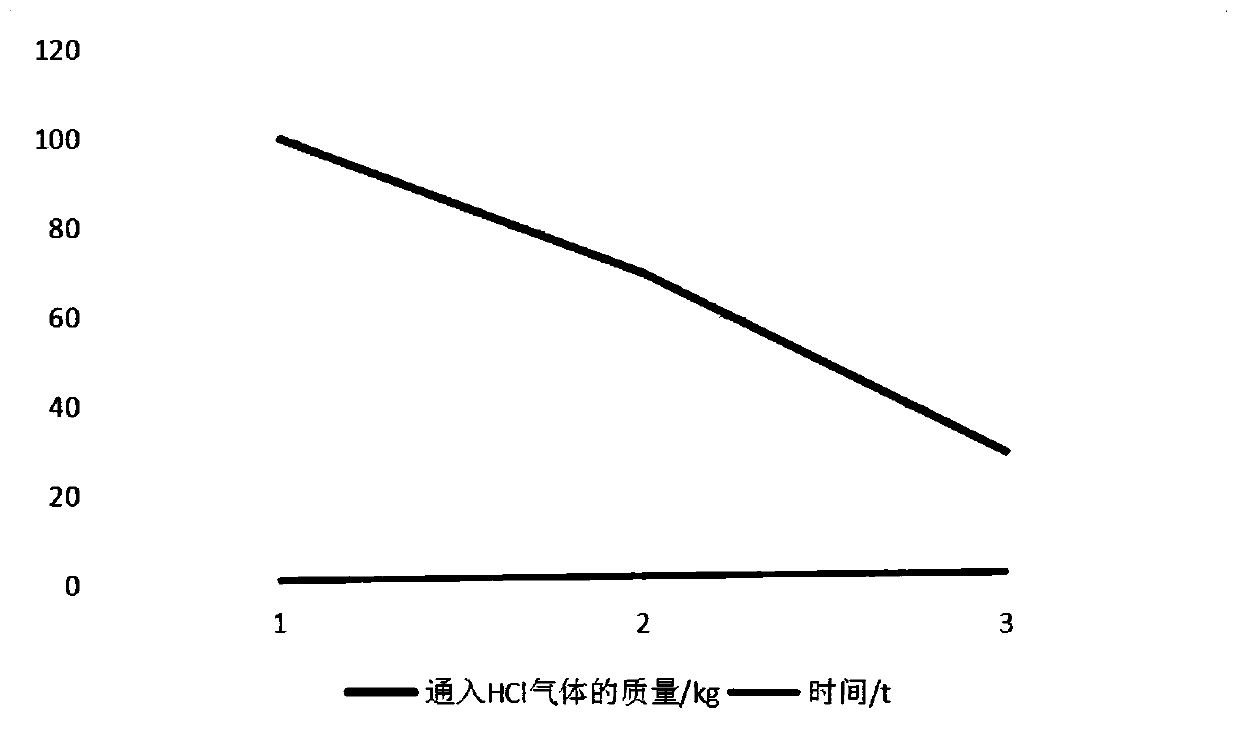

[0038] c. After the water has been added, continue to feed HCl gas into the reactor for 3 hours. The feed rate of the first 1.5h HCl gas is 85kg / h, and the feed rate of the latter 1.5h HCl gas is 50kg / h (such as image 3 As shown, the quality of passing HCl gas in the reactor is inversely proportional to the time); its HCl gas needs to pass under the liquid level of the pickling waste liquid;

[0039] d. Ferrous chloride tetrahydrate crystals are continuously precipitated in the pickling waste liquid during the treatment process. After 5 hours, the reaction en...

Embodiment 12

[0041] A waste acid recovery method for treating steel pickling waste liquid, comprising the following steps:

[0042] a. Collect the pickling waste liquid obtained by cleaning the steel with hydrochloric acid in the acid liquid collection tank, and put 1.5 tons of pickling waste liquid in a 2.5-ton closed reaction kettle through a lift pump;

[0043]b. Before passing HCl gas, add 108 kg of 7% dilute hydrochloric acid solution to the reactor at one time;

[0044] c. After the addition of hydrochloric acid is completed, continue to feed HCl gas into the reactor for 2.5 hours. The feed rate of HCl gas for the first 1.8h is 135kg / h, and the feed rate of HCl gas for the last 0.7h is 78kg / h; Pass into the pickling waste liquid surface;

[0045] d. During the treatment process, ferrous chloride tetrahydrate crystals are continuously precipitated in the pickling waste liquid, and the reaction is complete after 5.5 hours. The supernatant is filtered to obtain a hydrochloric acid solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com