Method for preparing spherical nickel-based powder

A nickel-based powder, spherical technology, applied in the field of spherical nickel-based powder preparation, can solve the problems of reducing the performance of the final alloy, limiting the application of nano-oxide dispersion-strengthened nickel-based alloys, and poor powder fluidity, to achieve nano-oxide dispersed phase Small, controllable product composition, strong designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

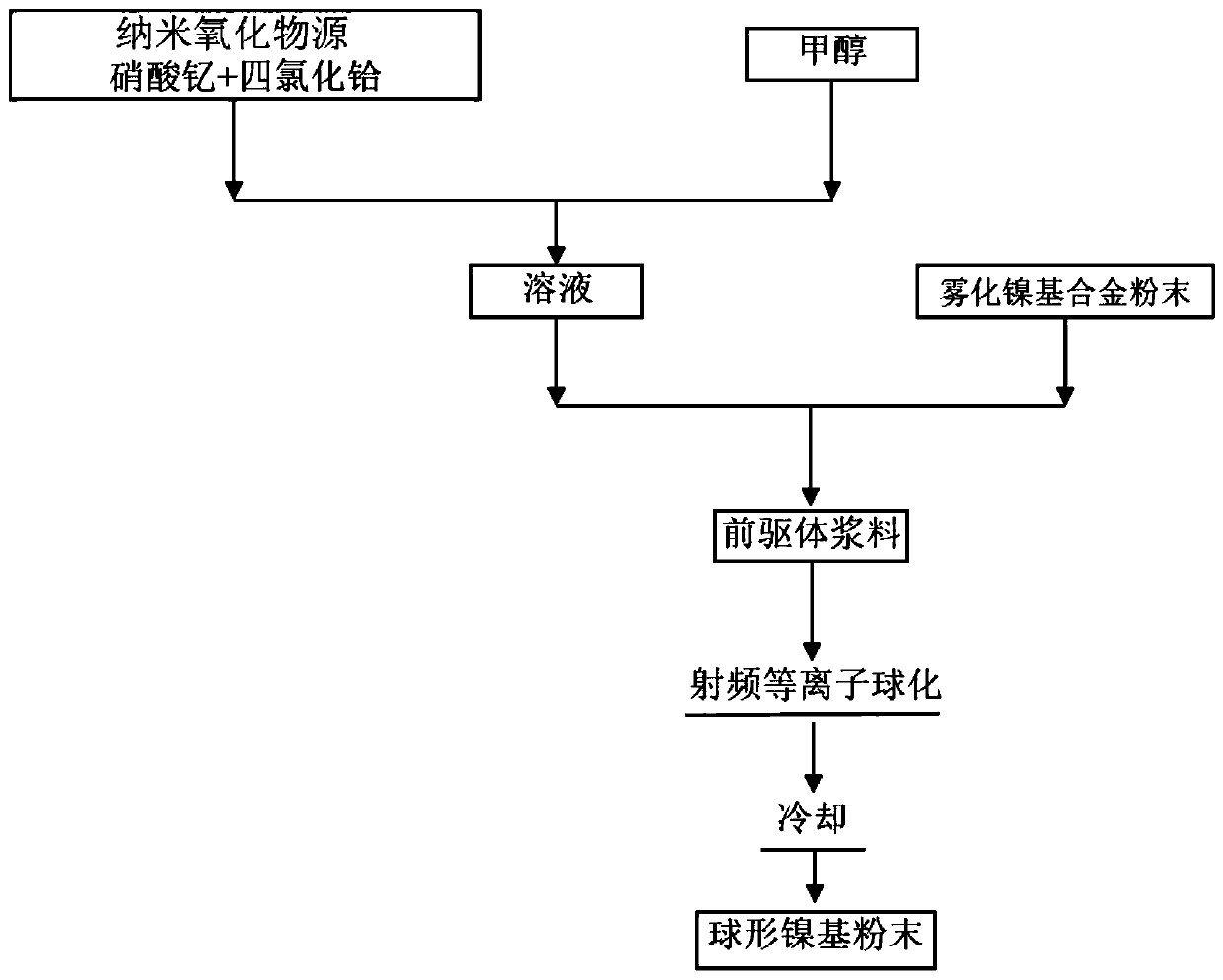

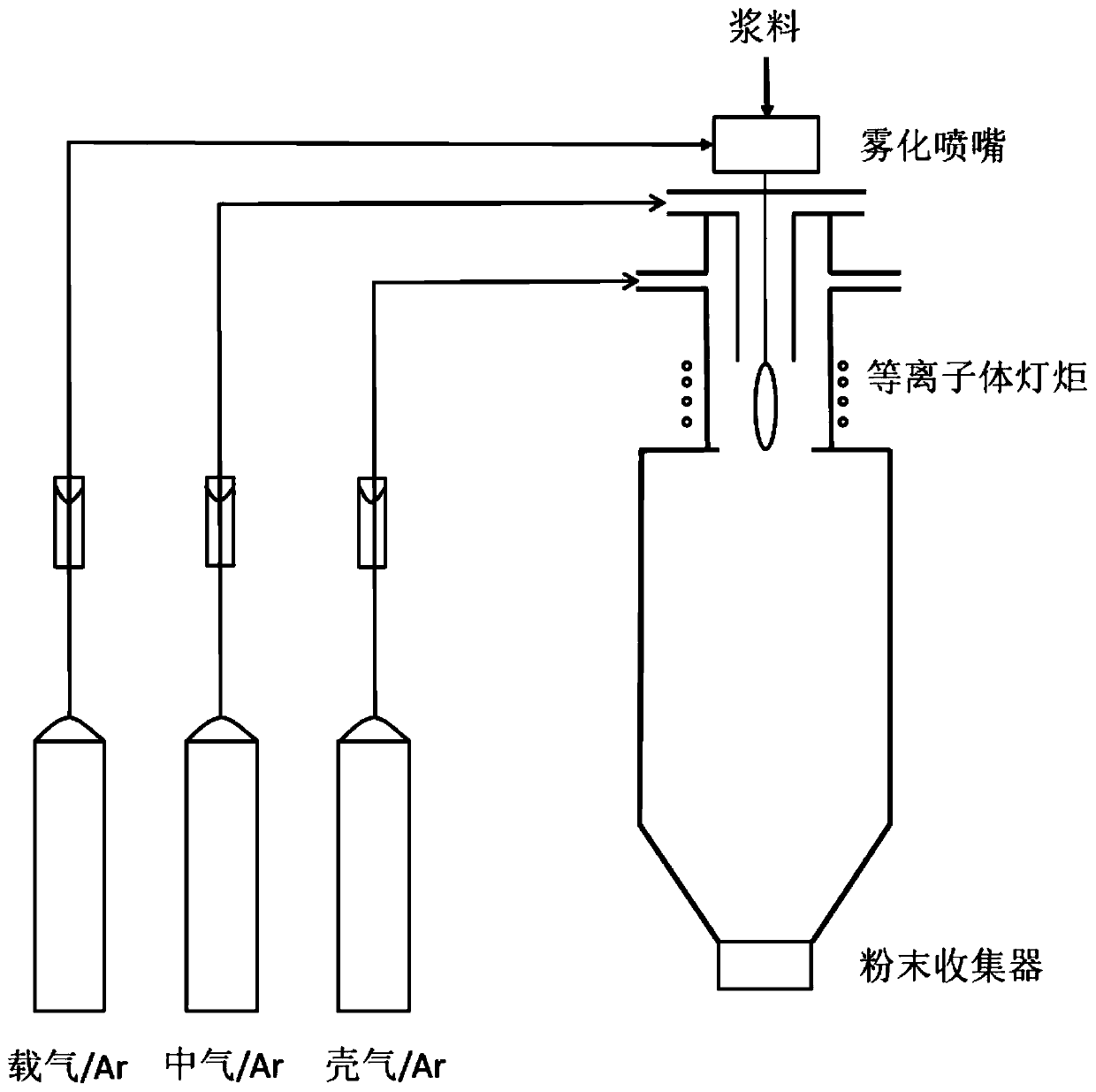

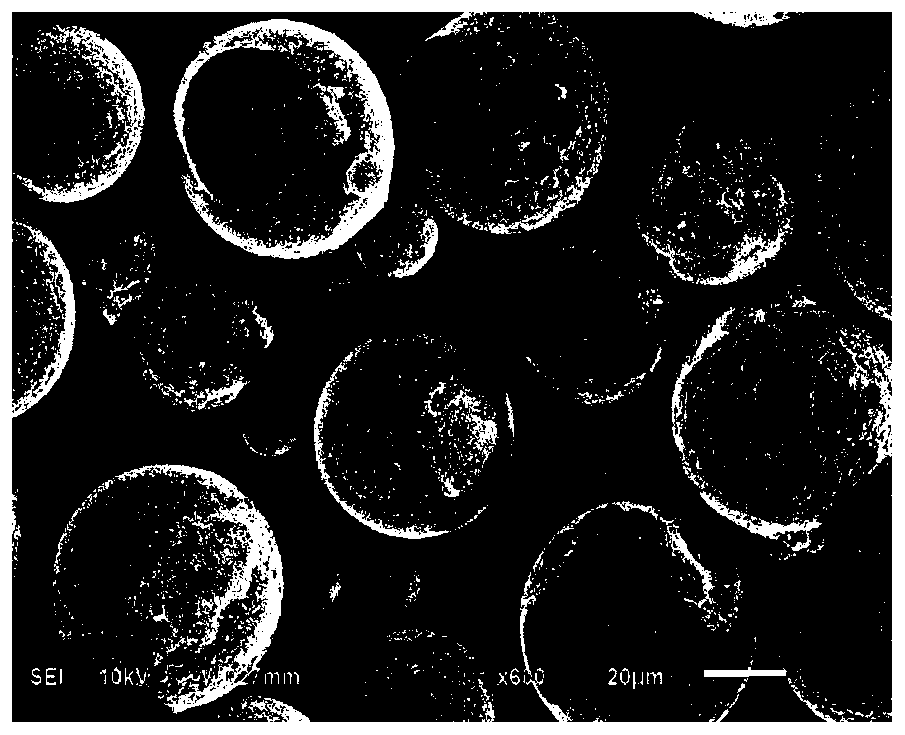

[0028] S2. Preparation of spherical nickel-based powder products: The obtained precursor slurry is subjected to radio frequency plasma spheroidization, and the precursor slurry is transported to the atomization nozzle by the carrier gas for atomization to obtain atomized powder, and then reaches the high temperature of radio frequency plasma heating zone, first decomposes and reacts to obtain the corresponding oxide nanoparticles, then the atomized powder and oxide nanoparticles are heated and melted by radio frequency plasma, and then become spherical under the action of surface tension, and are cooled to obtain spherical nickel-based powder .

[0029] According to an embodiment of the present disclosure, the nano-oxide source in S1 includes yttrium nitrate and hafnium tetrachloride, and the mass ratio of the two is 1.197:1.

[0030] According to an embodiment of the present disclosure, the nickel-based alloy gas atomized powder in S1 is various standard grades of nickel-base...

Embodiment 1

[0038] Example 1: Ni–20wt%Cr–3wt%Fe–0.5wt%Ti–0.3wt%Al–1wt%Y 2 f 2 o 7 Preparation of spherical ODS nickel-based powder

[0039] The gas-atomized powder and yttrium nitrate (Y(NO 3 ) 3 ·6H 2 O) and hafnium tetrachloride (HfCl 4 ) with a mass ratio of 100.101:1.197:1 and weigh it for later use. Dissolve the weighed aluminum nitrate and hafnium tetrachloride in an appropriate amount of methanol, and stir evenly in a container to form a transparent solution. Add the atomized powder and an appropriate amount of methanol into the solution evenly until the alloy powder is just wetted by methanol. Next, a mixer was used to mix for 2.5 hours at a rotational speed of 40 rpm to obtain a precursor slurry. During the radio frequency plasma spheroidization process, the negative pressure is 7200Pa; the middle gas is argon, and the flow rate of the middle gas is 22L / min; the shell gas is argon, and the flow rate of the shell gas is 70L / min; The gas sprays the precursor solution into th...

Embodiment 2

[0040] Embodiment 2: Ni-17wt%Cr-2wt%Mo-3.5wt%W-2wt%Ta-6.6wt%Al-1.1wt%Y 2 f 2 o 7 Preparation of spherical nickel-based powder

[0041] Atomized powder and yttrium nitrate (Y(NO 3 ) 3 ·6H 2 O) and hafnium tetrachloride (HfCl 4 ) Weigh it with a mass ratio of 90.901:1.197:1 for later use. Dissolve the weighed yttrium nitrate and hafnium tetrachloride in an appropriate amount of methanol, and stir in a container to form a transparent solution. Then, the atomized powder and an appropriate amount of methanol were evenly added into the solution until the alloy powder was just wetted by methanol, and then mixed at a speed of 40 rpm for 4 hours using a mixer to obtain a precursor slurry. During the radio frequency plasma spheroidization process, the negative pressure is 7800Pa; the middle gas is argon, and the flow rate of the middle gas is 24L / min; the shell gas is argon, and the flow rate of the shell gas is 74L / min; the carrier gas is 6L / min The gas sprays the precursor sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com