Preparation method of honeycomb sandwich structure wave-absorbing composite filled with bowknot-shaped Co/C nano wave-absorbing material

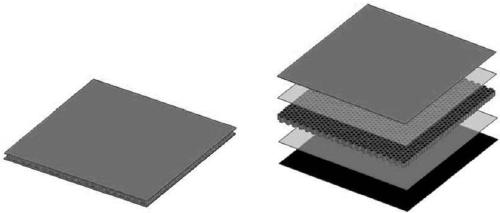

A nano-wave absorbing material, honeycomb sandwich structure technology, applied in chemical instruments and methods, magnetic/electric field shielding, synthetic resin layered products, etc., can solve the problems of poor mechanical bearing capacity, difficult to meet, easy to wear and fall off Achieve the effect of improving the structural bearing and absorbing performance, improving the overall mechanical strength, and realizing the effect of broadband absorbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Dissolve cobalt nitrate and urea in deionized water with high-speed magnetic stirring for 30 minutes until completely dissolved to obtain liquid A; heat gelatin at 50°C and dissolve in deionized water under medium-speed magnetic stirring conditions, and keep stirring for 30 minutes to obtain liquid B; then add cobalt nitrate and urea mixed solution and gelatin solution (i.e. liquid A and liquid B) into a 250mL single-necked flask and mix, and react with magnetic stirring under heating conditions to obtain cobalt ion-gelatin molecule metal ion polymer organic framework purple colloid mixture.

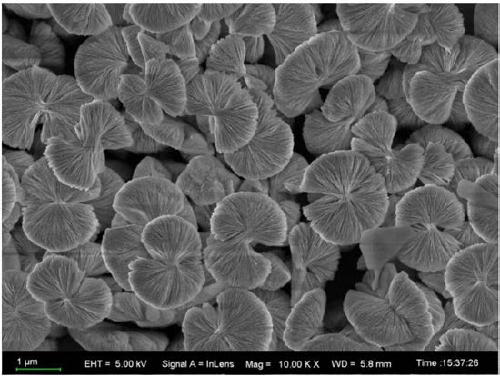

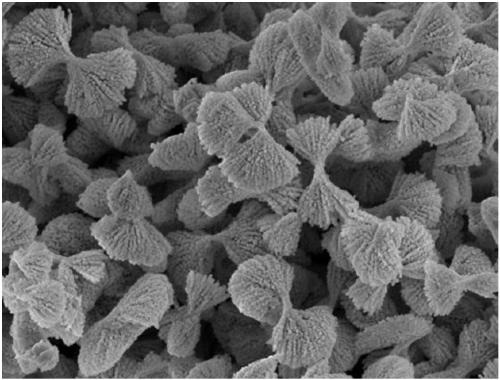

[0025] (2) Take the purple colloidal mixed solution obtained in (1) and add it to a 100mL polytetrafluoroethylene liner reactor, and hydrothermally react for a certain period of time to obtain a bow-tie-shaped precursor (see attached figure 1 ), the precipitate was collected by centrifugation, and dried for 24 h for later use.

[0026] (3) Place the dried bowtie-shaped precur...

Embodiment 2

[0033](1) Dissolve cobalt nitrate and urea in deionized water with high-speed magnetic stirring for 30 minutes until completely dissolved to obtain liquid A; heat gelatin at 50°C and dissolve in deionized water under medium-speed magnetic stirring conditions, and keep stirring for 30 minutes to obtain liquid B; then add cobalt nitrate and urea mixed solution and gelatin solution (i.e. liquid A and liquid B) into a 250mL single-necked flask and mix, and react with magnetic stirring under heating conditions to obtain cobalt ion-gelatin molecule metal ion polymer organic framework purple colloid mixture.

[0034] (2) Take the purple colloidal mixed solution obtained in (1) and add it to a 100mL polytetrafluoroethylene liner reactor, hydrothermally react for a certain period of time to obtain a bowtie-shaped precursor, collect the precipitate by centrifugation, and dry it for 24 hours before use.

[0035] (3) The dried bowtie-shaped precursor sample obtained in (2) was placed in a...

Embodiment 3

[0042] (1) Dissolve cobalt nitrate and urea in deionized water with high-speed magnetic stirring for 30 minutes until completely dissolved to obtain liquid A; heat gelatin at 50°C and dissolve in deionized water under medium-speed magnetic stirring conditions, and keep stirring for 30 minutes to obtain liquid B; then add cobalt nitrate and urea mixed solution and gelatin solution (i.e. liquid A and liquid B) into a 250mL single-necked flask and mix, and react with magnetic stirring under heating conditions to obtain cobalt ion-gelatin molecule metal ion polymer organic framework purple colloid mixture.

[0043] (2) Take the purple colloidal mixed solution obtained in (1) and add it to a 100mL polytetrafluoroethylene liner reactor, hydrothermally react for a certain period of time to obtain a bowtie-shaped precursor, collect the precipitate by centrifugation, and dry it for 24 hours before use.

[0044] (3) The dried bowtie-shaped precursor sample obtained in (2) was placed in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap