Titanium-based tin antimony oxide electrode modified by titanium dioxide network structure and preparation method thereof

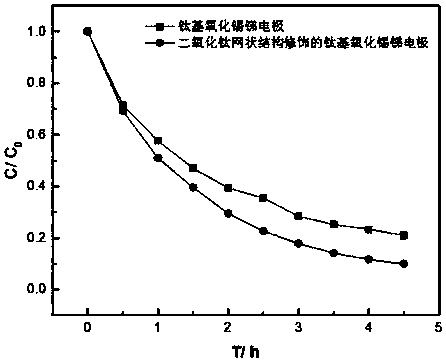

A technology of network structure and titanium dioxide, which is applied in the field of environmental protection technology and electrochemistry, can solve the problems of undiscovered patent documents, etc., and achieve the effects of enhanced binding force, strong electrocatalytic ability, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

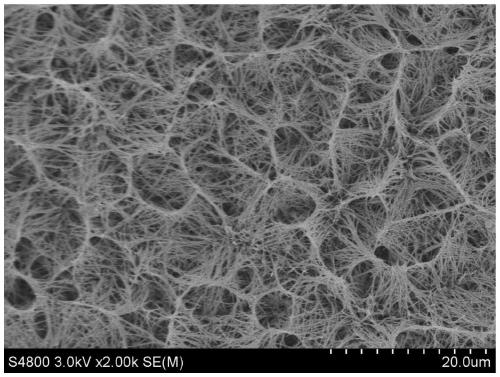

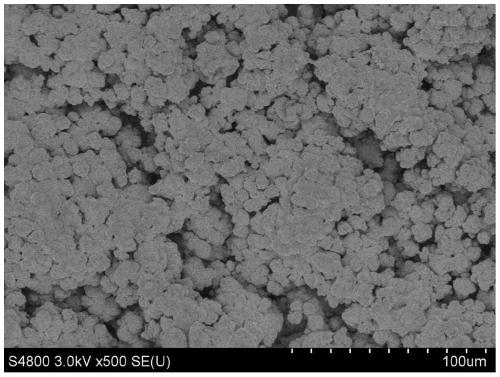

[0028] A titanium-based tin-antimony oxide electrode modified with a titanium dioxide network structure, including a titanium substrate and a catalytic layer, and its innovation is that it also includes an intermediate layer. After the titanium substrate undergoes a hydrothermal synthesis reaction, titanium dioxide is formed on its surface The middle layer of the network structure, and then the surface tin antimony coating is formed on the middle layer of the network structure by pulse electrodeposition method and temperature-programmed annealing activation method, and the surface tin antimony oxide coating is the tin antimony oxide catalytic layer .

[0029] The surface of the middle layer of the titanium dioxide network structure is composed of mesh holes with an average diameter of 5 μm, and the mesh holes are covered with filamentous fibers, and the average width of each filamentary fiber is less than 100 nm.

[0030] A method for preparing a titanium-based tin oxide antim...

Embodiment 2

[0051] Step (1) is the same as step (1) in Example 1;

[0052] (2) Synthesis of titanium dioxide network structure by hydrothermal method

[0053] Using the hydrothermal method, use 0.025mol of sodium hydroxide, 6mL of absolute ethanol and 29mL of deionized water to prepare the precursor solution, put it in a 50mL polytetrafluoro reactor together with the pretreated titanium substrate, and put it at 200 °C Hydrothermal reaction at high temperature for 14 hours, after cooling with the furnace, take out the titanium substrate; soak it in 0.1mol / L hydrochloric acid for 9 hours, then rinse it repeatedly with deionized water and dry it; place the dried electrode in a muffle furnace, Raise the temperature at a heating rate of 10°C / min, keep it at 400°C for 3 hours, take it out after natural cooling, and obtain a titanium dioxide network structure;

[0054] (3) Hydrogenation treatment of titanium dioxide network structure

[0055] The cathodic electroreduction method is adopted, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com