A method for advanced treatment of fluorine-containing wastewater

A technology for advanced treatment and waste water, applied in water/sewage multi-stage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc., can solve high investment cost and operation cost, frequent and complicated regeneration and backwashing , production cost waste and other issues, to achieve the effect of improving synergy, improving the effect of fluorine removal, and increasing the surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

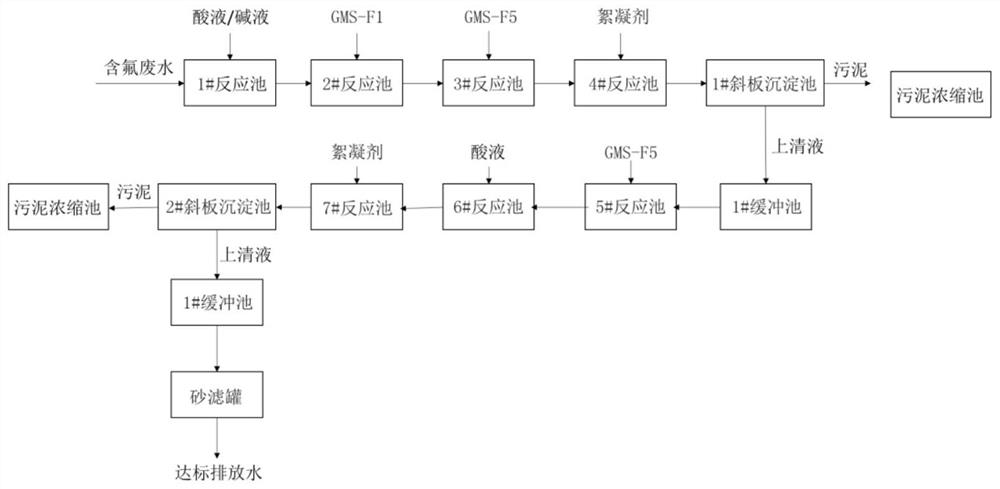

[0032] A method for advanced treatment of fluorine-containing wastewater, comprising the steps of:

[0033] (1) Preprocessing section:

[0034] S1: Fluoride-containing wastewater (fluorine ion content is 400mg / L) enters the 1# reaction pool, and according to the pH of the wastewater, add a pH regulator such as hydrochloric acid or liquid alkali to the 1# reaction pool to adjust the pH value of the wastewater to 7.5- 8. Stay for 10 minutes;

[0035] S2: Introduce the upper wastewater treated by the 1# reaction pool into the 2# reaction pool, and add the high-efficiency defluoridation agent GMS-F1 and the reaction catalyst to the 2# reaction pool according to the content of fluoride ions in the wastewater, among which, GMS-F1 The mass ratio of the dosing mass of the catalyst to the mass of fluoride ions in the waste water is 18:1, the mass ratio of the mass of the reaction catalyst to the mass of fluorine ions in the waste water is 0.1:1, and the upper layer of waste water is i...

Embodiment 2

[0044] A method for advanced treatment of fluorine-containing wastewater, comprising the steps of:

[0045] (1) Preprocessing section:

[0046] S1: Fluorine-containing waste water (fluorine ion content is 400mg / L) enters the 1# reaction pool, and according to the pH of the waste water, add a pH regulator to the 1# reaction pool, adjust the pH value of the waste water to 7.5-8, and stay for 10 minutes;

[0047] S2: Introduce the upper wastewater treated by the 1# reaction pool into the 2# reaction pool, and add the high-efficiency defluoridation agent GMS-F1 and the reaction catalyst to the 2# reaction pool according to the content of fluoride ions in the wastewater, among which, GMS-F1 The mass ratio of the dosing mass of the reaction catalyst to the mass of fluoride ions in the waste water is 15:1, the mass ratio of the mass of the reaction catalyst to the mass of fluorine ions in the waste water is 0.1:1, and the upper layer of waste water is introduced into the 3# reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com