Efficient rare earth modified defluorination material and preparation method thereof

A technology of rare earth modification and fluorine materials, applied in chemical instruments and methods, other chemical processes, magnesium oxide, etc., can solve the problem of insufficient stability of loaded rare earth elements, and achieve the effect of enhancing fluorine removal effect, reducing temperature and stabilizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

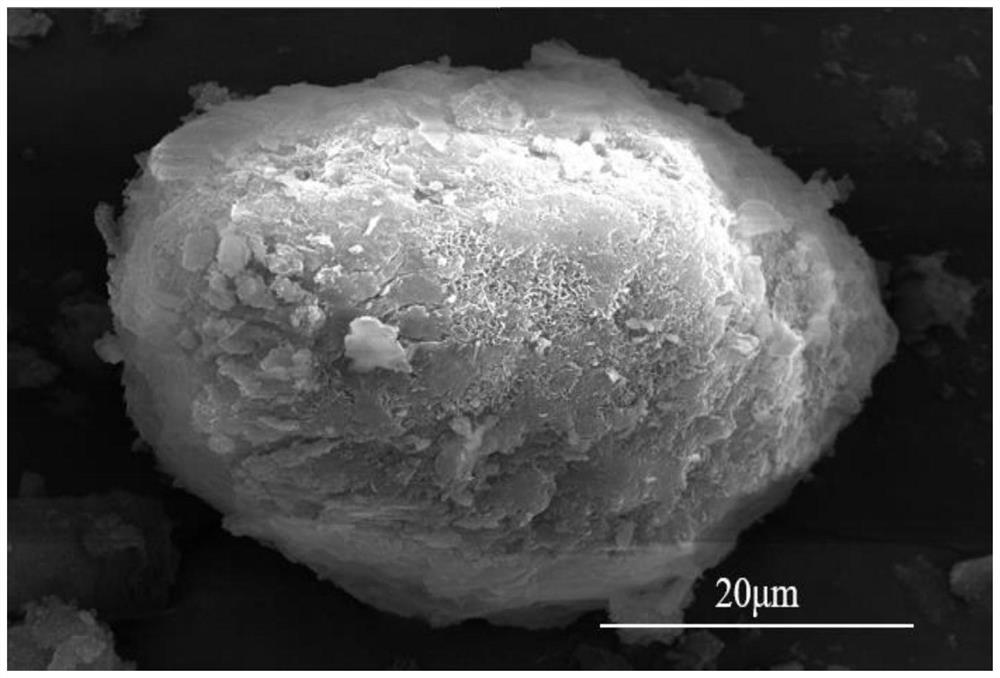

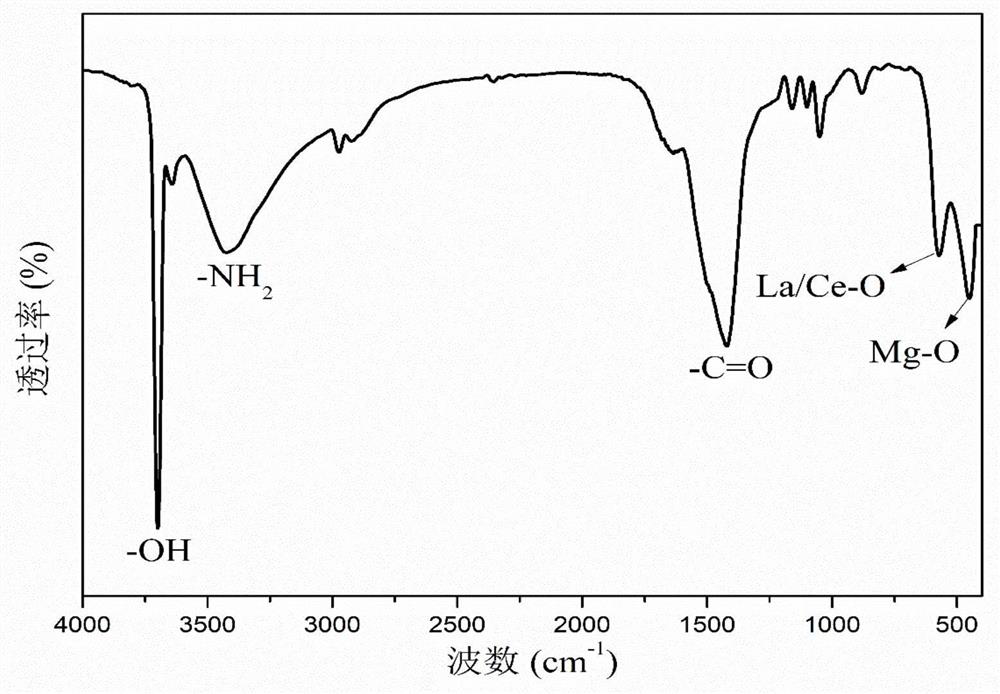

Image

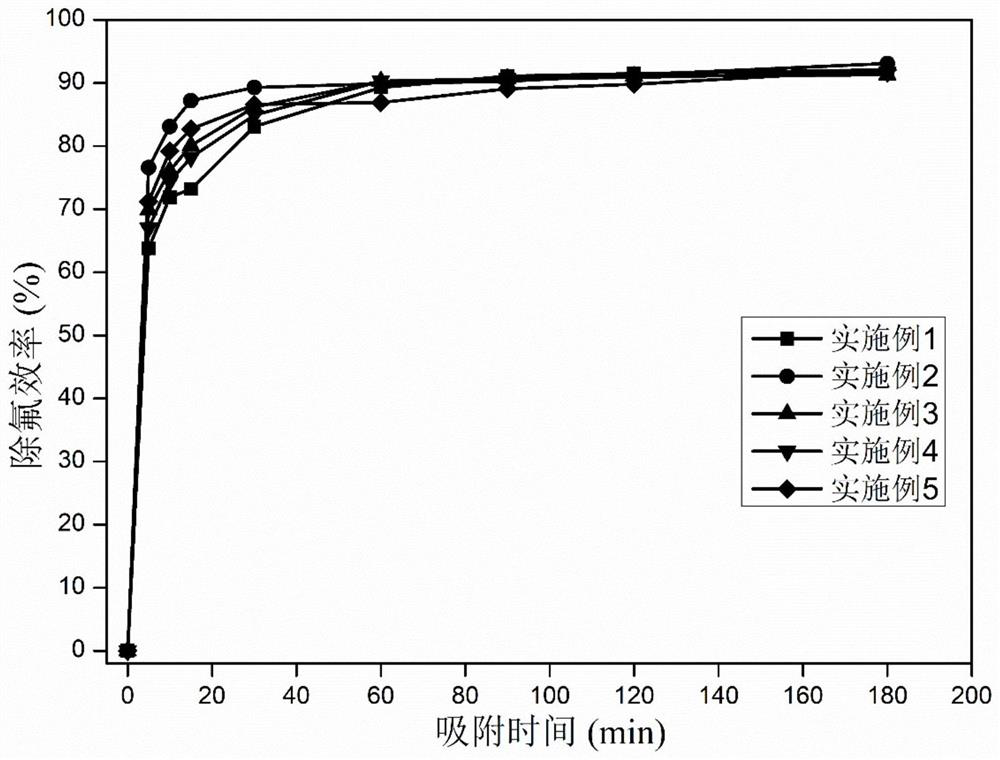

Examples

Embodiment 1

[0036] The high-efficiency rare earth modified fluorine removal material and the preparation method thereof of the present embodiment include the following steps:

[0037] 1) At 25°C, weigh 10g of magnesium sulfate, 2g of urea and 10g of water, add them to the pressure reaction kettle and mix, then react at 110°C for 10h under a sealed condition, cool to room temperature, filter, and wash the filter cake by centrifugation 3 times with water, Dry at 60°C for 12h to obtain magnesium carbonate;

[0038] 2) At 25°C, weigh 1g of magnesium carbonate, 0.01g of cetyltrimethylammonium bromide and 5g of water into the reaction kettle, stir for 10h, filter, and dry the filter cake at 60°C for 12h, dry and grind it into powder. Placed in a tube furnace and heated to 500°C at a heating rate of 0.1°C / min, and then annealed to room temperature for 5 hours to obtain positively charged magnesium oxide;

[0039] 3) At 25°C, weigh 1g of lanthanum nitrate, 40g of water and 0.3g of Octapa chelati...

Embodiment 2

[0044] The high-efficiency rare earth modified fluorine removal material and the preparation method thereof of the present embodiment include the following steps:

[0045] 1) At 25°C, weigh 10g of magnesium nitrate, 3g of urea and 15g of water, add them to the pressure reaction kettle and mix, then react at 100°C for 12h under a sealed condition, cool to room temperature, filter, and centrifuge the filter cake with water for 5 times, Dry at 70°C for 11h to obtain magnesium carbonate;

[0046] 2) At 25°C, weigh 1g of magnesium carbonate, 0.02g of cetyltrimethylammonium chloride and 10g of water into the reaction kettle, stir for 12h, filter, dry the filter cake at 80°C for 10h, and dry it into powder. Placed in a tube furnace and heated to 500°C at a heating rate of 0.5°C / min, and then annealed to room temperature for 5 hours to obtain positively charged magnesium oxide;

[0047] 3) At 25°C, weigh 1g of lanthanum acetate, 50g of water and 0.35g of Pypa chelating agent, add it ...

Embodiment 3

[0052] The high-efficiency rare earth modified fluorine removal material and the preparation method thereof of the present embodiment include the following steps:

[0053] 1) At 25°C, weigh 10g of magnesium acetate, 2g of urea and 20g of water, add them into a pressure reactor and mix well, then react at 110°C for 10h under a sealed condition, cool down to room temperature, filter, and centrifuge the filter cake with water for 5 times, Dry at 60°C for 12h to obtain magnesium carbonate;

[0054] 2) At 25°C, weigh 1g of magnesium carbonate, 0.03g of cetyltrimethylammonium chloride and 5g of water, add them to the reaction kettle, stir for 12h, filter, and dry the filter cake at 60°C for 12h, and grind it into powder. Placed in a tube furnace and heated to 600°C at a heating rate of 1°C / min, and then annealed to room temperature for 6 hours to obtain positively charged magnesium oxide;

[0055] 3) At 25°C, weigh 1g of cerium nitrate, 40g of water and 0.4g of DOTA chelating agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com