Polyacid Ag(I) coordination polymer as well as preparation method and application thereof

A technology of coordination polymers and acid groups, applied in the field of electrochemical catalysis, can solve the problems of undiscovered and less research on electrocatalytic activity, and achieve the effects of simple preparation process, good electrocatalytic activity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

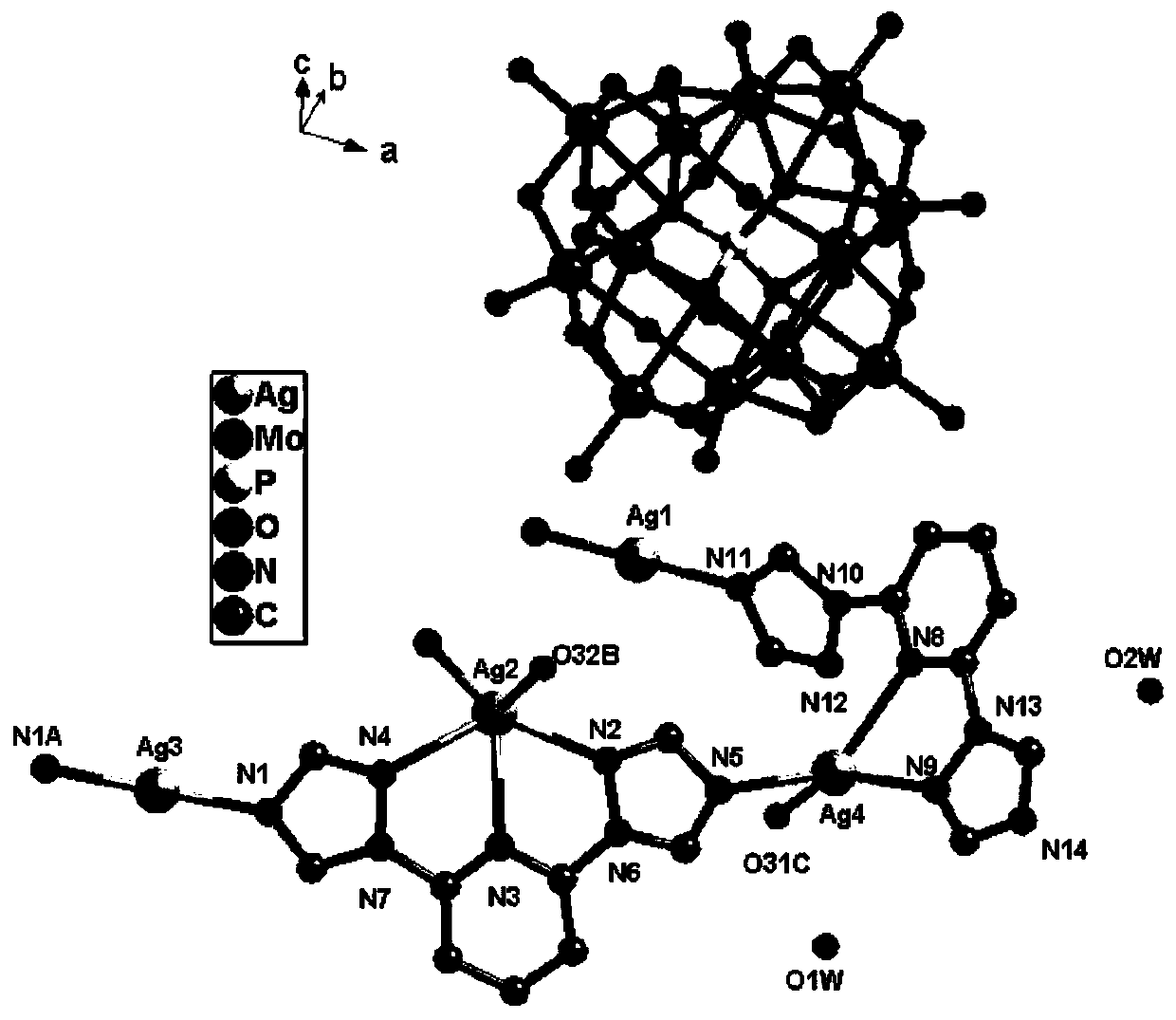

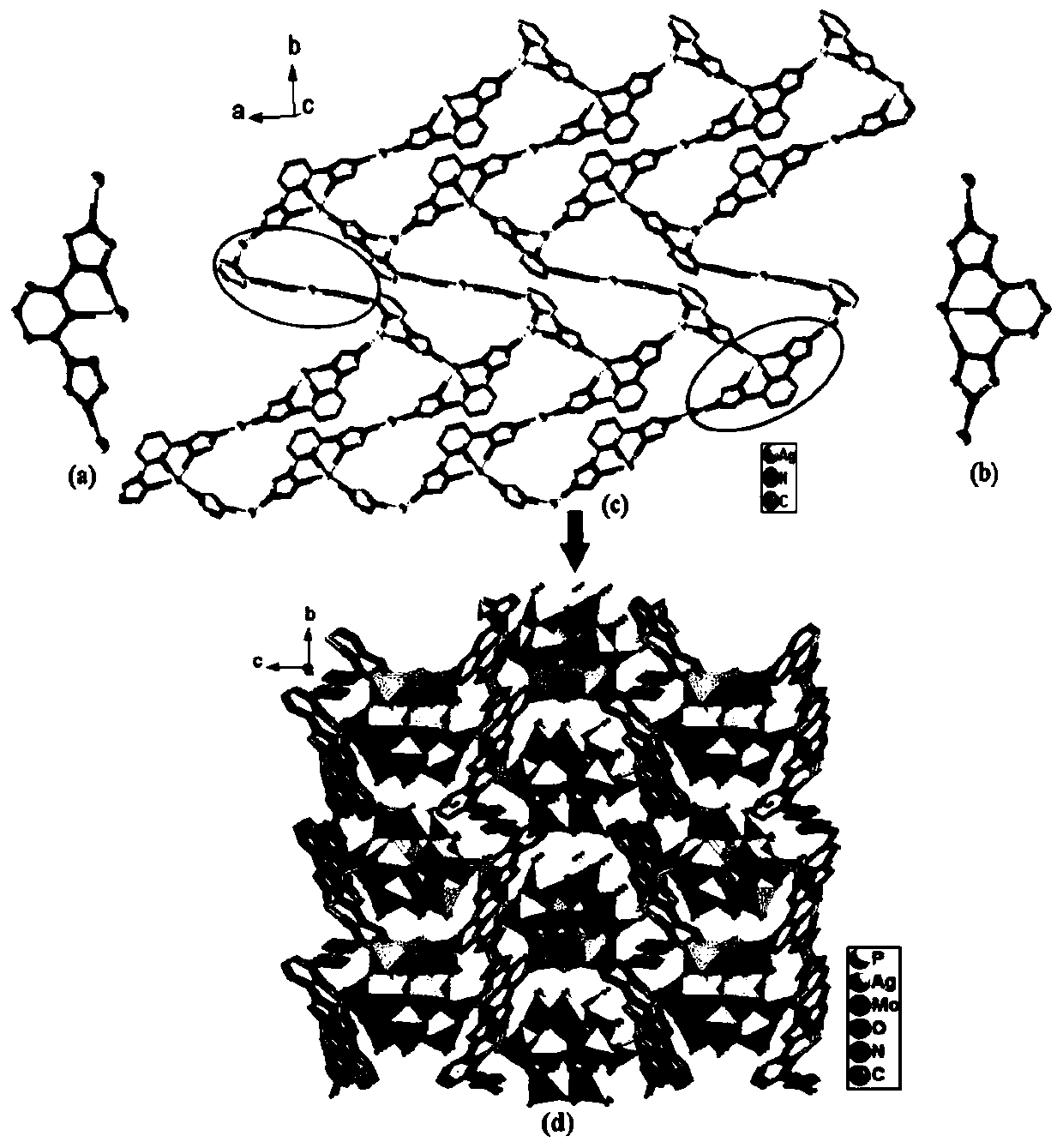

[0024] Example 1 Synthesis of polyacid-based Ag(I) coordination polymer

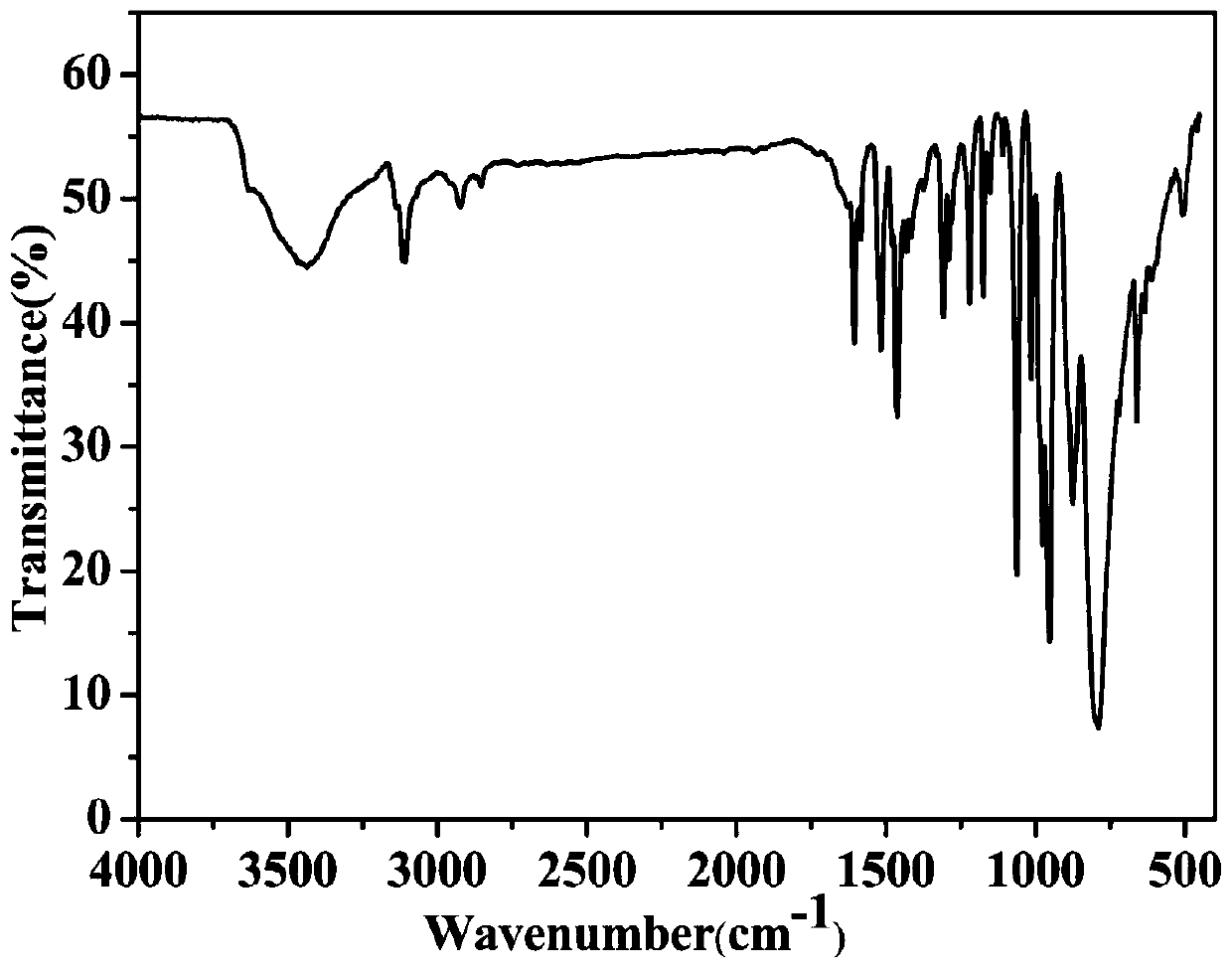

[0025] AgNO 3 (0.1mmol), H 3 PMo 12 O 40The mixture of (0.05mmol), btp (0.2mmol) and 8ml of distilled water was put into a 25ml reactor, stirred for 40min to uniformly mixed, in the stirring process, the pH of the solution was adjusted to 2.1 with HCl, heated at 150°C for five days, and cooled to room temperature After washing, filtering and drying, golden yellow massive crystals were obtained. Yield: 63.2%. Chemical formula of the obtained crystal: Ag 3 PMo 12 C 18 H 17 N 14 O 41.5 ; Elemental analysis: theoretical value: C 8.32, H 0.66, N 7.54; experimental value: C 8.26, H 0.59, N 7.67. Infrared spectrum (cm -1 ): 3440(w), 3120(w), 1609(m), 1527(m), 1460(m), 1310(w), 1222(w), 1170(w), 1065(s), 961(s) ), 877(s), 798(s).

Embodiment 2

[0026] Example 2 Synthesis of polyacid-based Ag(I) coordination polymer

[0027] AgNO 3 (0.1mmol), H 3 PMo 12 O 40 The mixture of (0.04mmol), btp (0.22mmol) and 7ml of distilled water was put into a 25ml reactor, stirred for 35min to uniformly mixed, in the stirring process, the pH of the solution was adjusted to 1.8 with HCl, heated at 140°C for six days, and cooled to room temperature After washing, filtering and drying, golden yellow massive crystals were obtained with a yield of 40.2%.

Embodiment 3

[0028] Example 3 Synthesis of Polyacid Ag(I) Coordination Polymer

[0029] AgNO 3 (0.1mmol), H 3 PMo 12 O 40 The mixture of (0.06mmol), btp (0.19mmol) and 9ml of distilled water was put into a 25ml reactor, stirred for 45min until uniformly mixed, and the pH of the solution was adjusted to 2.3 with HCl during stirring, heated at 160°C for four days, and cooled to room temperature After washing, filtering and drying, golden yellow massive crystals were obtained with a yield of 21.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com