Preparation method for colorful polyurethane and artificial leather

A technology of polyurethane and water-based polyurethane, applied in coating, textile and papermaking, etc., can solve the problems of low compatibility and fastness of direct mixing method, complicated preparation process, etc., and achieve good application prospects, simple process and good dispersion. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

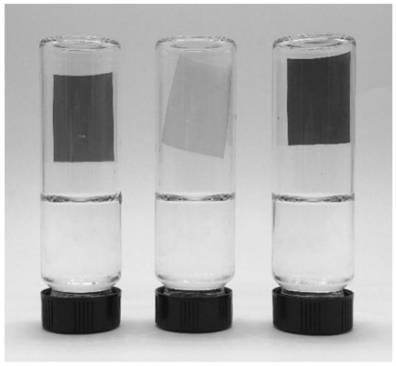

Embodiment 1

[0030] 1) prepare the regenerated cellulose suspension that concentration is 0.5wt% by phosphoric acid method;

[0031] 2) Mix 0.1g of reactive red 194 dye, 45g of the regenerated cellulose suspension prepared in step 1), 3g of sodium chloride, 1.2g of sodium carbonate and an appropriate amount of water in a total of 50mL, and heat up at a rate of 2°C / min To the color fixing temperature of 70°C, after dyeing for 90 minutes, the stock solution of the colored regenerated cellulose suspension is obtained;

[0032] 3) Use deionized water to fully wash the stock solution by filtration or centrifugation to remove unfixed reactive dyes to obtain the final red regenerated cellulose suspension;

[0033] 4) Take 10g of the red regenerated cellulose suspension obtained in step 3), mix with 30g of anionic water-based polyurethane emulsion and a total of 50mL of an appropriate amount of water, and mix uniformly, wherein the concentration of the red regenerated cellulose suspension is 1wt%,...

Embodiment 2

[0037] 1) preparing a regenerated cellulose suspension with a concentration of 1 wt% by the sodium hydroxide / urea method;

[0038] 2) Mix 0.1g of reactive yellow 145 dyestuff, 60g of the regenerated cellulose suspension prepared in step 1), 3g of sodium chloride, 1.2g of sodium carbonate and an appropriate amount of water in a total of 70mL, and heat up at a rate of 3°C / min To the color fixing temperature of 80°C, after dyeing for 60 minutes, the stock solution of the colored regenerated cellulose suspension is obtained;

[0039]3) Use deionized water to fully wash the stock solution by filtration or centrifugation to remove unfixed reactive dyes to obtain the final yellow regenerated cellulose suspension;

[0040] 4) Take 10g of the yellow regenerated cellulose suspension obtained in step 3), mix with 20g of anionic water-based polyurethane emulsion and a total of 50mL of an appropriate amount of water, and mix evenly, wherein the concentration of the yellow regenerated cellu...

Embodiment 3

[0044] 1) preparing a regenerated cellulose suspension with a concentration of 1.5 wt% by an ionic liquid method;

[0045] 2) Mix 0.1g of reactive blue 19 dye, 75g of the regenerated cellulose suspension prepared in step 1), 3g of sodium chloride, 1.2g of sodium carbonate and an appropriate amount of water in a total of 80mL, and heat up at a rate of 1°C / min To the color fixing temperature of 50°C, after dyeing for 120 minutes, the stock solution of the colored regenerated cellulose suspension is obtained;

[0046] 3) Use deionized water to fully wash the stock solution by filtration or centrifugation to remove unfixed reactive dyes to obtain the final blue regenerated cellulose suspension;

[0047] 4) Take 10 g of the blue regenerated cellulose suspension obtained in step 3), mix with 10 g of anionic water-based polyurethane emulsion and a total of 50 mL of an appropriate amount of water, and mix uniformly, wherein the concentration of the blue regenerated cellulose suspensio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com