Lithium ion battery electrolyte and preparation method thereof

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve problems such as the effect of reducing impedance, battery appearance, and increasing impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

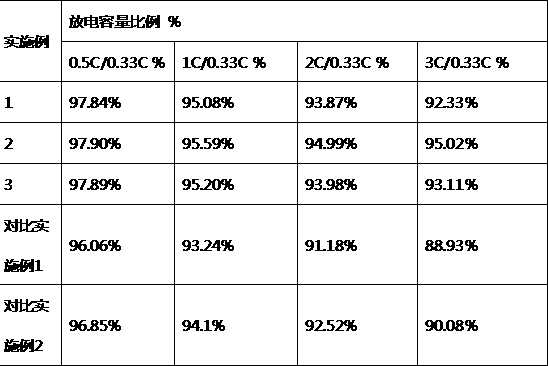

Embodiment 1

[0017] (1) Preparation of electrolyte:

[0018] In a glove box filled with argon (moisture content<0.1ppm, oxygen content<0.1ppm), ethylene carbonate and diethyl carbonate were mixed uniformly at a mass ratio of 1:2 and stirred continuously, and added to the mixed solvent Slowly add 1.0mol / L lithium hexafluorophosphate, and then add electrolyte additive with a mass fraction of 5.0%, wherein the ratio of lithium difluorophosphate: TMSB: VC: TMSP is 1.0~1.5:1:1:1, stir until completely dissolved , that is, the electrolyte solution of this embodiment is obtained.

[0019] (2) Preparation of lithium ion battery:

[0020] Using NCM811 as the positive electrode active material and graphite as the negative electrode active material, add a conductive agent, a binder and a solvent and mix them well, and then coat them on aluminum foil and copper foil respectively, and then dry, roll, and shear. Positive and negative pole pieces. The positive and negative pole pieces and the polyprop...

Embodiment 2

[0022] (1) Preparation of electrolyte:

[0023] In a glove box filled with argon (moisture content < 0.1ppm, oxygen content < 0.1ppm), mix ethylene carbonate and diethyl carbonate in a mass ratio of 1:2 and stir continuously, slowly add to the mixed solvent Add 1.0mol / L lithium hexafluorophosphate, and then add 5.0% of the electrolyte additive in the total mass fraction of the electrolyte, wherein the ratio of lithium difluorophosphate: TMSB: VC: TMSP is 1.50~1.55:1:1:1, and stir until Dissolve completely, promptly obtain the electrolyte solution of this embodiment.

[0024] (2) Preparation of lithium ion battery:

[0025] Using NCM811 as the positive electrode active material and graphite as the negative electrode active material, add a conductive agent, a binder and a solvent to fully stir and mix them evenly, and then coat them on aluminum foil and copper foil, dry them, roll them, and cut them to obtain a positive electrode. , Negative pole piece. The positive and negat...

Embodiment 3

[0027] (1) Preparation of electrolyte:

[0028] In a glove box filled with argon (moisture content < 0.1ppm, oxygen content < 0.1ppm), mix ethylene carbonate and diethyl carbonate in a mass ratio of 1:2 and stir continuously, slowly add to the mixed solvent Add 1.0 mol / L lithium hexafluorophosphate, and then add 5.0% electrolyte additives accounting for the total mass fraction of the electrolyte, wherein the ratio of lithium difluorophosphate: TMSB: VC: TMSP is 2.0~2.5:1:1:1, and stir until Dissolve completely, promptly obtain the electrolyte solution described in this embodiment.

[0029] (2) Preparation of lithium ion battery:

[0030] Using NCM811 as the positive electrode active material and graphite as the negative electrode active material, add a conductive agent, a binder and a solvent to fully stir and mix them evenly, and then coat them on aluminum foil and copper foil, dry them, roll them, and cut them to obtain a positive electrode. , Negative pole piece. The pos...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap