A kind of anti-haze function waterproof membrane material for building and its preparation method

A waterproof membrane and anti-smog technology, which is applied to building insulation materials, buildings, building components, etc., can solve the problems of difficult construction and poor anti-smog effect, and achieve easy haze removal, excellent anti-smog effect, and easy construction convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

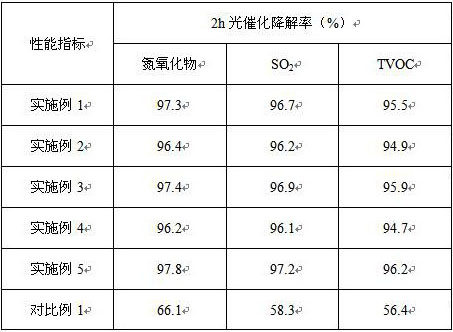

Examples

Embodiment 1

[0027]34kg of molybdenum disulfide nanosheets were first ultrasonically cleaned with absolute ethanol for 7 minutes, then cleaned with acetone for 7 minutes, then immersed in a solution of 17kg of zinc acetate dihydrate and 49kg of methanol, dispersed evenly, and then sealed and placed in a constant temperature oven at 66°C to keep warm After treatment for 35 hours, the reaction product was filtered and taken out, heated to 470°C, and subjected to constant temperature annealing treatment for 1.5 hours to obtain molybdenum disulfide with a zinc oxide seed layer on the surface; then 9kg of zinc acetate dihydrate and 7kg of hexamethylenetetramine were added 50kg of distilled water was prepared as a growth solution, and then 34kg of molybdenum disulfide that formed a zinc oxide seed layer on the surface was dispersed in the growth solution, heated to 86°C, and reacted at a constant temperature for 7 hours, so that zinc oxide nanostructures grew on the surface of molybdenum disulfide...

Embodiment 2

[0029] 33kg of molybdenum disulfide nanosheets were first ultrasonically cleaned with absolute ethanol for 6 minutes, then cleaned with acetone for 9 minutes, then immersed in a solution of 16kg of zinc acetate dihydrate and 51kg of methanol, dispersed evenly, and then sealed and placed in a constant temperature oven at 62°C to keep warm After treatment for 44 hours, the reaction product was filtered and taken out, heated to 460°C, and subjected to constant temperature annealing treatment for 2 hours to obtain molybdenum disulfide with a zinc oxide seed layer on the surface; then 9kg of zinc acetate dihydrate and 6kg of hexamethylenetetramine were added to 52kg Prepare a growth solution in distilled water, then disperse 33 kg of molybdenum disulfide that forms a seed layer on the surface in the growth solution, heat to 82°C, and react at a constant temperature for 12 hours, so that zinc oxide nanostructures grow on the surface of the molybdenum disulfide. After the end, the prod...

Embodiment 3

[0031] Clean 38kg molybdenum disulfide nanosheets ultrasonically for 9 minutes with absolute ethanol, then wash with acetone for 6 minutes, then immerse in a solution of 18kg zinc acetate dihydrate and 44kg methanol, disperse evenly, and then seal and place in a constant temperature oven at 68°C to keep warm After treatment for 30 hours, the reaction product was filtered and taken out, heated to 480°C, and subjected to constant temperature annealing treatment for 1 hour to obtain molybdenum disulfide with a zinc oxide seed layer on the surface; then 11kg of zinc acetate dihydrate and 7kg of hexamethylenetetramine were added to 45kg Prepare a growth solution in distilled water, then disperse 37kg of molybdenum disulfide on the surface to form a seed layer in the growth solution, heat it to 88°C, and react at a constant temperature for 3 hours, so that zinc oxide nanostructures grow on the surface of the molybdenum disulfide. After the end, the product is centrifuged , and then u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com