Boron-10 zirconium target material decomposition recycling method

A technology of boric acid and powder, which is applied in the chemical field, can solve the problems affecting the decomposition of zirconium boride and the strong corrosion effect of boron-10 acid, and achieve the effects of high recovery rate, convenient operation and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

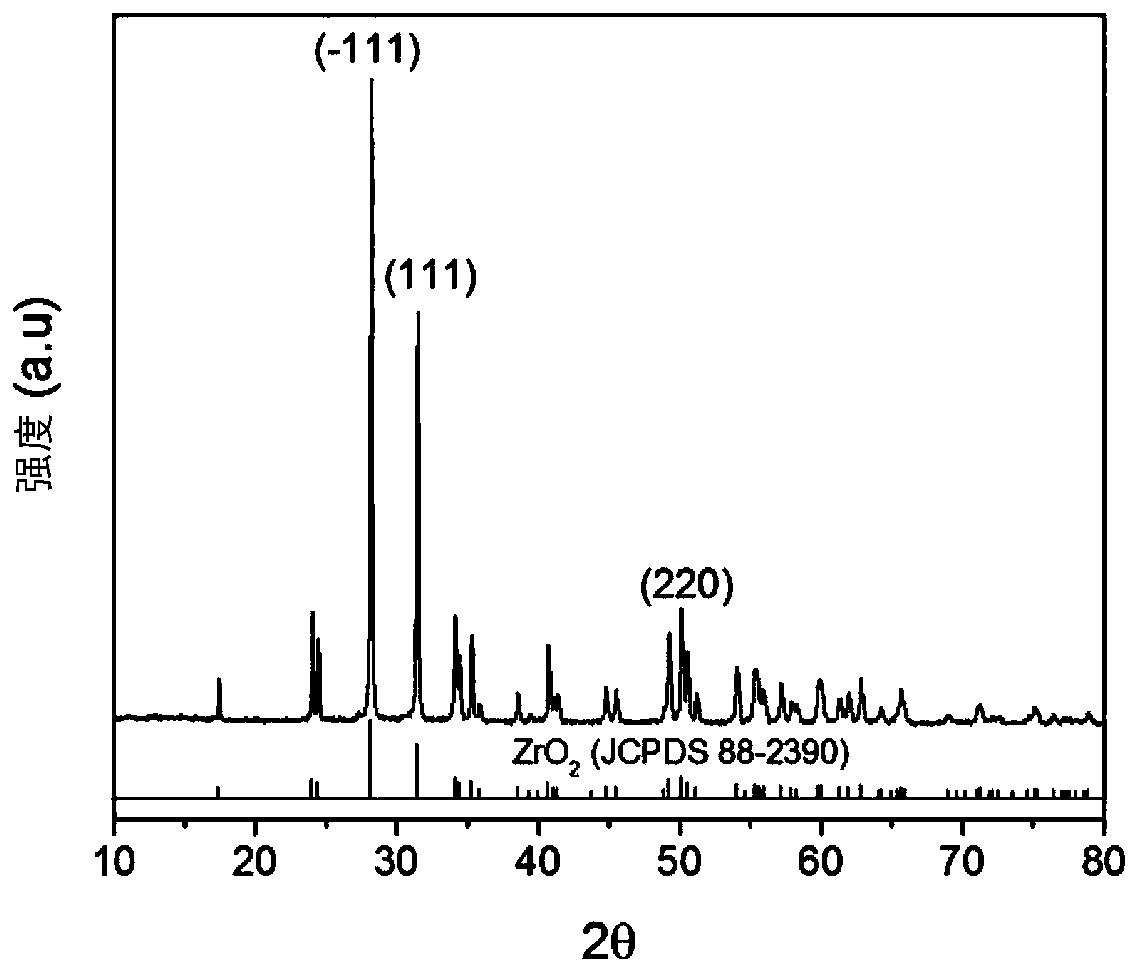

Image

Examples

Embodiment 1

[0042] Break the boron-10 zirconium target material and pass through a 160-mesh sieve. The particle size of the boron-10 zirconium powder is less than 0.1mm. Take 200g of boron-10 zirconium powder after sieving and put it into a quartz crucible. The quartz crucible filled with boron-10 zirconium is placed in the constant temperature zone of the quartz tube furnace, and the two ends are kept warm with zirconia sheets;

[0043] Raise the temperature to 900°C at a heating rate of 100°C / h;

[0044] Quickly pass 10ml of deionized water to make it gasify, then continue to pass the water, and adjust the water flow to 1-5ml / min;

[0045] Introduce oxygen, the oxygen flow rate is 3ml / min;

[0046] Constant temperature 60h;

[0047] Cool down to room temperature at a cooling rate of 100°C / h;

[0048] Take out the zirconia sheet and quartz crucible in the reverse order of the installation procedure;

[0049] Clean the quartz tube and zirconia sheet with deionized water, and recover t...

Embodiment 2

[0055] Break the boron-10 zirconium target material and pass through a 160-mesh sieve. The particle size of the boron-10 zirconium powder is less than 0.1mm. Take 200g of boron-10 zirconium powder after sieving and put it into a quartz crucible. The quartz crucible filled with boron-10 zirconium is placed in the constant temperature zone of the quartz tube furnace, and the two ends are kept warm with zirconia sheets;

[0056] Raise the temperature to 800°C at a heating rate of 100°C / h;

[0057]Quickly pass 10ml of deionized water to make it gasify, then continue to pass the water, and adjust the water flow to 1-5ml / min;

[0058] Introduce oxygen, the oxygen flow rate is 3ml / min;

[0059] Constant temperature 60h;

[0060] Cool down to room temperature at a cooling rate of 100°C / h;

[0061] Take out the zirconia sheet and quartz crucible in the reverse order of the installation procedure;

[0062] Clean the quartz tube and zirconia sheet with deionized water, and recover th...

Embodiment 3

[0068] The boron-10 zirconium target is crushed and passed through a 160-mesh sieve. The particle size of the boron-10 zirconium powder is less than 0.1 mm. Take 200 g of boron-10 zirconium powder after sieving and put it into a quartz crucible. The quartz crucible filled with boron-10 zirconium is placed in the constant temperature zone of the quartz tube furnace, and the two ends are kept warm with zirconia sheets;

[0069] Heat up to 1000°C at a heating rate of 100°C / h;

[0070] Quickly pass 10ml of deionized water to make it gasify, then continue to pass the water, and adjust the water flow to 1-5ml / min;

[0071] Introduce oxygen, the oxygen flow rate is 3ml / min;

[0072] Constant temperature 60h;

[0073] Cool down to room temperature at a cooling rate of 100°C / h;

[0074] Take out the zirconia sheet and quartz crucible in the reverse order of the installation procedure;

[0075] Clean the quartz tube and zirconia sheet with deionized water, and recover the cleaning s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com