Black-odor river channel treatment process

A treatment process and river channel technology, applied in gas treatment, precipitation treatment, special treatment targets, etc., can solve the problems of low product added value, low treatment efficiency, and high treatment cost, solve the problem of collection and enrichment, and reduce odor. concentration, the effect of improving the pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

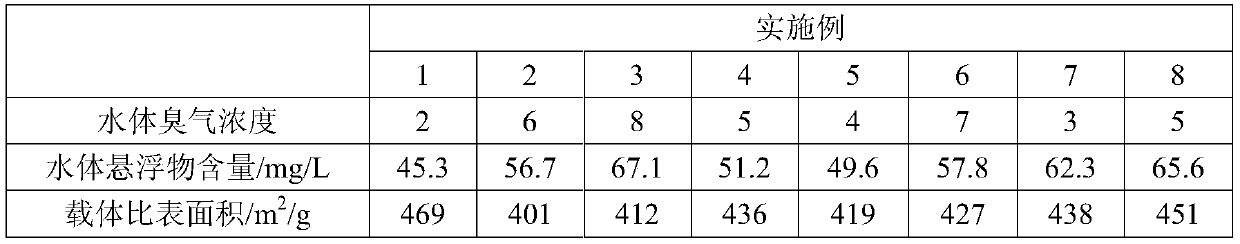

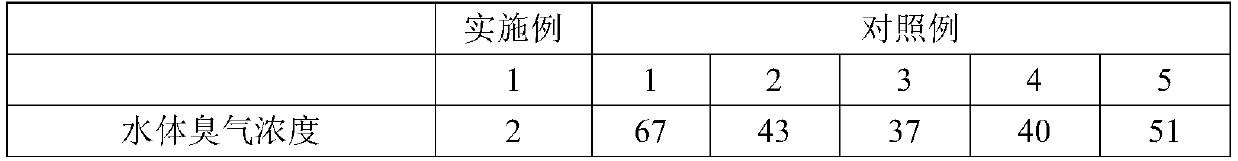

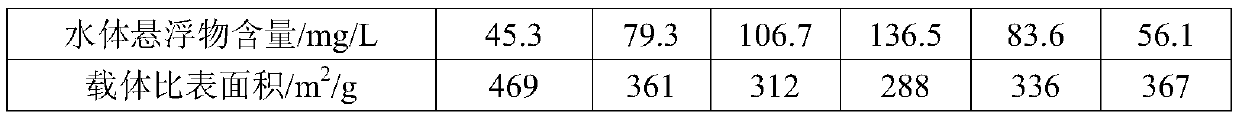

Examples

Embodiment 1

[0019] A treatment process for black and odorous rivers, the treatment process comprising the following steps:

[0020] (1) Black and odorous river sewage pretreatment

[0021] Automatically add 1.5 parts of polyaluminum chloride aqueous solution and 0.25 parts of palladium-carbon mixture to 1 m through a venturi tube 3 In the river sewage, after the materials are mixed evenly by the dynamic mixing tube, the above-mentioned mixed solution is pumped to the sedimentation tank to stand for 30 minutes, and 0.8 parts of basic polyaluminum chloride aqueous solution and 0.12 parts of palladium carbon are automatically added to the supernatant through the Venturi tube In the process, after the materials are mixed by the dynamic mixing tube, the above-mentioned mixed solution is pumped to the sedimentation tank to stand for 30 minutes, and 0.3 parts of polyacrylamide flocculant aqueous solution and 0.13 parts of palladium carbon are automatically added to the clear liquid through the V...

Embodiment 2

[0027] A treatment process for black and odorous rivers, the treatment process comprising the following steps:

[0028] (1) Black and odorous river sewage pretreatment

[0029] Automatically add 0.8 parts of polyaluminum chloride aqueous solution and 0.1 parts of palladium-carbon mixture to 1 m through a venturi tube 3 In the river sewage, after the materials are mixed evenly by the dynamic mixing tube, the above-mentioned mixed solution is pumped to the sedimentation tank to stand for 30 minutes, and 0.5 parts of basic polyaluminum chloride aqueous solution and 0.07 parts of palladium carbon are automatically added to the supernatant through the Venturi tube In the process, after the materials are mixed by the dynamic mixing tube, the above-mentioned mixed solution is pumped to the sedimentation tank and left for 30 minutes, and 0.1 part of polyacrylamide flocculant aqueous solution and 0.05 part of palladium carbon are automatically added to the clear liquid through the Vent...

Embodiment 3

[0035] A treatment process for black and odorous rivers, the treatment process comprising the following steps:

[0036] (1) Black and odorous river sewage pretreatment

[0037] Automatically add 5 parts of polyaluminum chloride aqueous solution and 0.7 parts of palladium-carbon mixture to 1 m through a venturi tube 3 In the river sewage, after the materials are uniformly mixed by the dynamic mixing tube, the above-mentioned mixed solution is pumped to the sedimentation tank to stand for 30 minutes, and 4 parts of basic polyaluminum chloride aqueous solution and 0.5 part of palladium carbon are automatically added to the supernatant through the Venturi tube In the process, after the materials are mixed by the dynamic mixing tube, the above-mentioned mixed solution is pumped to the sedimentation tank to stand for 30 minutes, and 2 parts of polyacrylamide flocculant aqueous solution and 0.3 parts of palladium carbon are automatically added to the clear liquid through the Venturi ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com