Double-component aqueous inorganic zinc-enriched priming paint

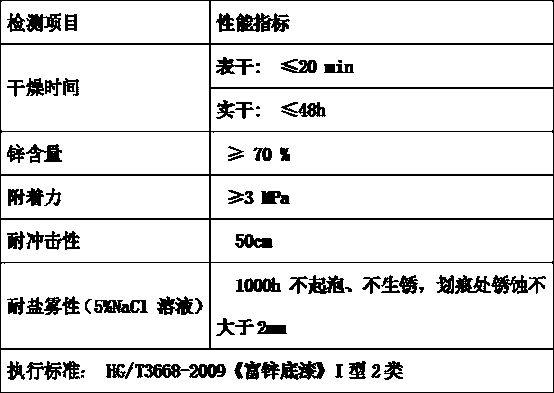

An inorganic zinc-rich, two-component technology, applied in coatings, chemical/physical/physicochemical processes, anti-corrosion coatings, etc., can solve the problems of poor paint adhesion, short anti-rust life, low viscosity, etc., to achieve strong adhesion Effects of concentration, less chemical reaction, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of a two-component water-based inorganic zinc-rich primer, characterized in that the preparation steps are as follows:

[0034] (1) Prepare zinc powder, mix 800-mesh zinc powder and 500-mesh zinc powder in a weight ratio of 3:4, and get zinc powder after mixing evenly;

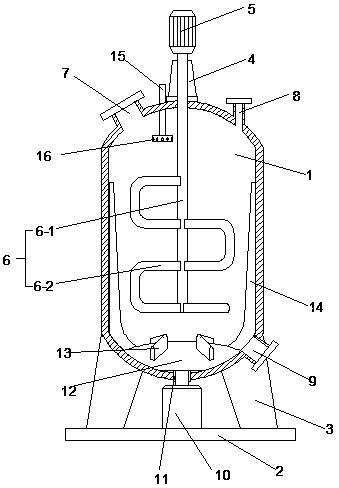

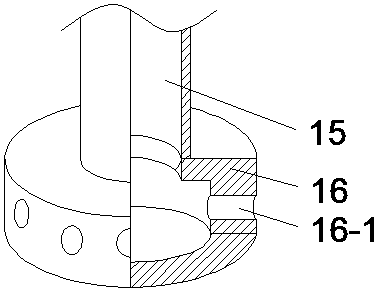

[0035] (2) To prepare component A, put water-based amino resin, acrylic emulsion, silica sol, and zinc powder into the paint letdown reaction kettle in sequence, stir for 2 hours, and stir at a rate of 800r / min, and get component A after stirring evenly;

[0036] (3) To prepare component B, put kaolin, modified nano-silicon dioxide, and deionized water into the paint letdown reaction kettle in sequence, stir for 2 hours, and stir at a rate of 800r / min, and get component B after stirring evenly;

[0037] (4) Put A component and B component into the paint mixing reaction kettle in turn, the stirring weight ratio is 7:3, the stirring time is 3H, the stirring speed is 900r / min, and the ...

Embodiment 2

[0059] Compared with Embodiment 1, the differences of this embodiment are:

[0060] A preparation method of a two-component water-based inorganic zinc-rich primer, characterized in that the preparation steps are as follows:

[0061] (1) Prepare zinc powder, mix 800-mesh zinc powder and 500-mesh zinc powder in a weight ratio of 3:4, and get zinc powder after mixing evenly;

[0062] (2) To prepare component A, put water-based amino resin, acrylic emulsion, silica sol, and zinc powder into the paint letdown reaction kettle in sequence, stir for 1 hour, and stir at a rate of 750r / min, and get component A after stirring evenly;

[0063] (3) To prepare component B, put kaolin, modified nano-silicon dioxide, and deionized water into the paint let-down reaction kettle in sequence, stir for 1 hour, and stir at a rate of 650r / min, and obtain component B after stirring evenly;

[0064] (4) Put A component and B component into the paint mixing reaction kettle in turn, the stirring weight...

Embodiment 3

[0075] A preparation method of a two-component water-based inorganic zinc-rich primer, characterized in that the preparation steps are as follows:

[0076] (1) Prepare zinc powder, mix 800-mesh zinc powder and 500-mesh zinc powder in a weight ratio of 3:4, and get zinc powder after mixing evenly;

[0077] (2) To prepare component A, put water-based amino resin, acrylic emulsion, silica sol, and zinc powder into the paint let-down reaction kettle in sequence, stir for 1.5 hours, and stir at a rate of 780r / min, and get component A after stirring evenly;

[0078] (3) To prepare component B, put kaolin, modified nano-silicon dioxide, and deionized water into the paint letdown reaction kettle in sequence, stir for 1.5 hours, and stir at a rate of 700r / min, and obtain component B after stirring evenly;

[0079] (4) Put component A and component B into the paint let-down reaction kettle in sequence, stirring weight ratio is 7:3, stirring time is 2H, stirring speed is 800r / min, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com