A kind of preparation method of alloy hydrogen evolution electrode loaded on foam transition metal

A transition metal and hydrogen evolution electrode technology, applied in the direction of electrodes, electrode shape/type, metal material coating process, etc., can solve the problems of waste liquid pollution of the environment, achieve mature and stable processes, increase the reaction contact area, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing an electrode prepared by a molybdenum-nickel-molybdenum alloy hydrogen evolution electrode loaded on nickel foam according to the present invention is carried out according to the following steps:

[0025] A. Degreasing and pickling the three-dimensional porous nickel-based electrode: first soak in NaOH solution with a mass fraction of less than 40% for 10-20 minutes, take it out and rinse it with deionized water for 3-5 times, and then put it in the mass Soak in hydrochloric acid solution with a fraction lower than 20% for 10-20 minutes, then take it out and rinse it with ultrapure water, place it in an oven at 80°C, and dry it for 3 hours before use;

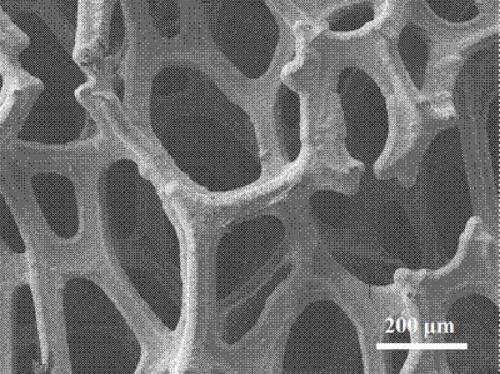

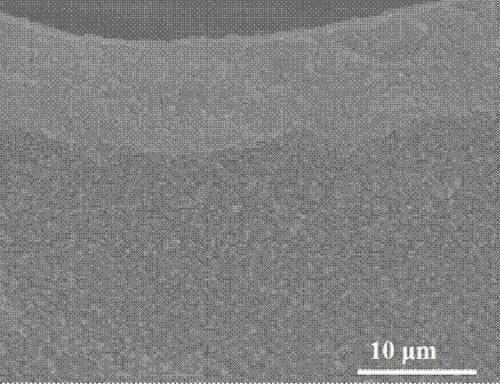

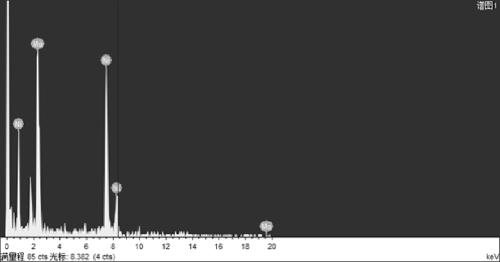

[0026] B. Place the dried three-dimensional porous nickel foam as a base material in a glow plasma metallization furnace. The three-dimensional foam transition metal has a porosity of 80% and a purity of 99.9%. A molybdenum plate with a purity of 99.99% is used as the splash Shooting targets, nick...

Embodiment 2

[0033] A method for preparing an electrode prepared by a molybdenum-cobalt molybdenum alloy hydrogen evolution electrode loaded on cobalt foam according to the present invention is carried out according to the following steps:

[0034] A. Degreasing and pickling the three-dimensional porous cobalt foam electrode: first soak in NaOH solution with a mass fraction of less than 40% for 10-20 minutes, take it out and rinse it with deionized water for 3-5 times, and then put it in the mass Soak in a boric acid solution with a fraction lower than 20% for 10-20 minutes, then take it out and rinse it with ultrapure water, place it in an oven at 80°C, and dry it for 3 hours before use;

[0035] B. Put the dried three-dimensional porous cobalt foam as the base material into the glow plasma metallization furnace. The porosity of the three-dimensional foam transition metal is 85%, the purity is 99.9%, and the molybdenum plate with a purity of 99.99% is used as the splash For shooting targe...

Embodiment 3

[0037] A method for preparing an electrode prepared by a molybdenum-iron-molybdenum alloy hydrogen evolution electrode loaded on iron foam according to the present invention is carried out according to the following steps:

[0038] A. Degreasing and pickling the three-dimensional porous foam iron matrix electrode: first soak in NaOH solution with a mass fraction of less than 40% for 10-20 minutes, take it out and rinse it with deionized water for 3-5 times, and then put it in the mass Soak in a dilute acid solution with a fraction lower than 20% for 10-20 minutes, then take it out and rinse it with ultrapure water, place it in an oven at 80°C, and dry it for 3 hours before use;

[0039]B. Put the dried three-dimensional porous iron foam as the substrate into the glow plasma metallization furnace. The porosity of the three-dimensional foam transition metal is 98%, the purity is 99.9%, and the molybdenum plate with the purity of 99.99% is used as the splash Shooting targets, foa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com