Preparation method of alloy hydrogen evolution electrode loaded on foam transition metal

A transition metal and hydrogen evolution electrode technology, applied in the direction of electrodes, electrode shape/type, metal material coating process, etc., can solve the problems of waste liquid pollution of the environment, etc., achieve mature and stable processes, not easily affected by the environment, and improve catalytic utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing an electrode prepared by a molybdenum-nickel-molybdenum alloy hydrogen evolution electrode loaded on nickel foam according to the present invention is carried out according to the following steps:

[0025] A. Degreasing and pickling the three-dimensional porous nickel-based electrode: first soak in NaOH solution with a mass fraction of less than 40% for 10-20 minutes, take it out and rinse it with deionized water for 3-5 times, and then put it in the mass Soak in hydrochloric acid solution lower than 20% for 10-20 minutes, then take it out and rinse it with ultrapure water, place it in an oven at 80°C, and dry it for 3 hours before use;

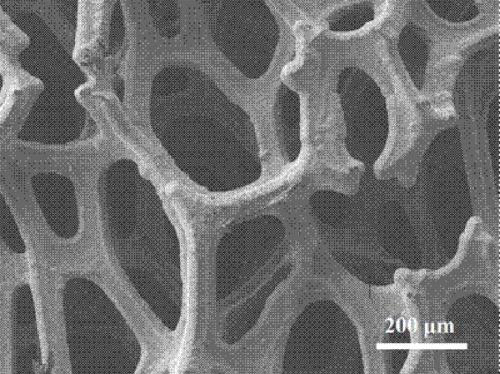

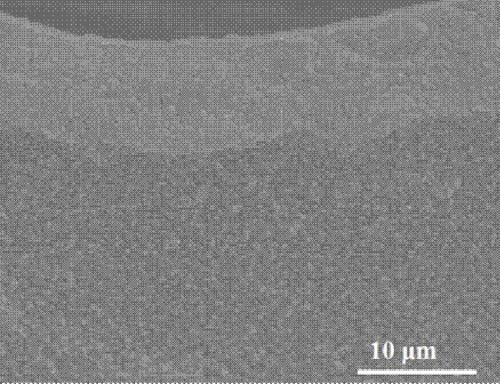

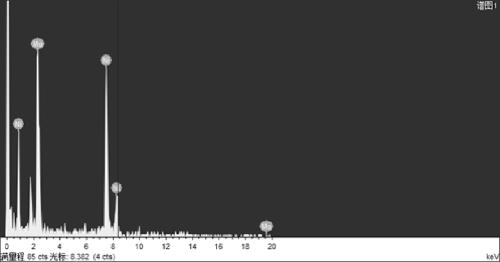

[0026] B. Place the dried three-dimensional porous nickel foam as a base material in a glow plasma metallization furnace. The three-dimensional foam transition metal has a porosity of 80% and a purity of 99.9%. A molybdenum plate with a purity of 99.99% is used as the splash Shooting targets, nickel foam and moly...

Embodiment 2

[0033] According to the present invention, an electrode preparation method prepared by a molybdenum-cobalt-molybdenum alloy hydrogen evolution electrode loaded on cobalt foam is carried out according to the following steps:

[0034] A. Degreasing and pickling the three-dimensional porous cobalt foam electrode: first soak in NaOH solution with a mass fraction of less than 40% for 10-20 minutes, take it out and rinse it with deionized water for 3-5 times, and then put it in the mass Soak in boric acid solution with less than 20% for 10-20 minutes, then take it out and rinse it with ultrapure water, place it in an oven at 80°C, and dry it for 3 hours before use;

[0035] B. Put the dried three-dimensional porous cobalt foam as the substrate into the glow plasma metallization furnace. The porosity of the three-dimensional foam transition metal is 85%, the purity is 99.9%, and the molybdenum plate with a purity of 99.99% is used as the splash Shooting targets, the vertical alignmen...

Embodiment 3

[0037] An electrode preparation method prepared by a molybdenum-iron-molybdenum alloy hydrogen evolution electrode loaded on foam iron according to the present invention is carried out according to the following steps:

[0038] A. Degreasing and pickling the three-dimensional porous foam iron matrix electrode: first soak in NaOH solution with a mass fraction of less than 40% for 10-20 minutes, take it out and rinse it with deionized water for 3-5 times, and then put it in the mass Soak in dilute acid solution less than 20% for 10-20 minutes, then take it out and rinse it with ultrapure water, place it in an oven at 80°C, and dry it for 3 hours before use;

[0039] B. Put the dried three-dimensional porous iron foam as the base material into the glow plasma metallization furnace. The three-dimensional foam transition metal has a porosity of 98%, a purity of 99.9%, and a molybdenum plate with a purity of 99.99% as the sputtering target Material, iron foam and molybdenum plate targ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com