Method for preparing membrane electrode of direct methanol fuel cell

A methanol fuel cell and membrane electrode technology, which is applied to battery electrodes, circuits, electrical components, etc., and can solve problems such as the decline in catalyst utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

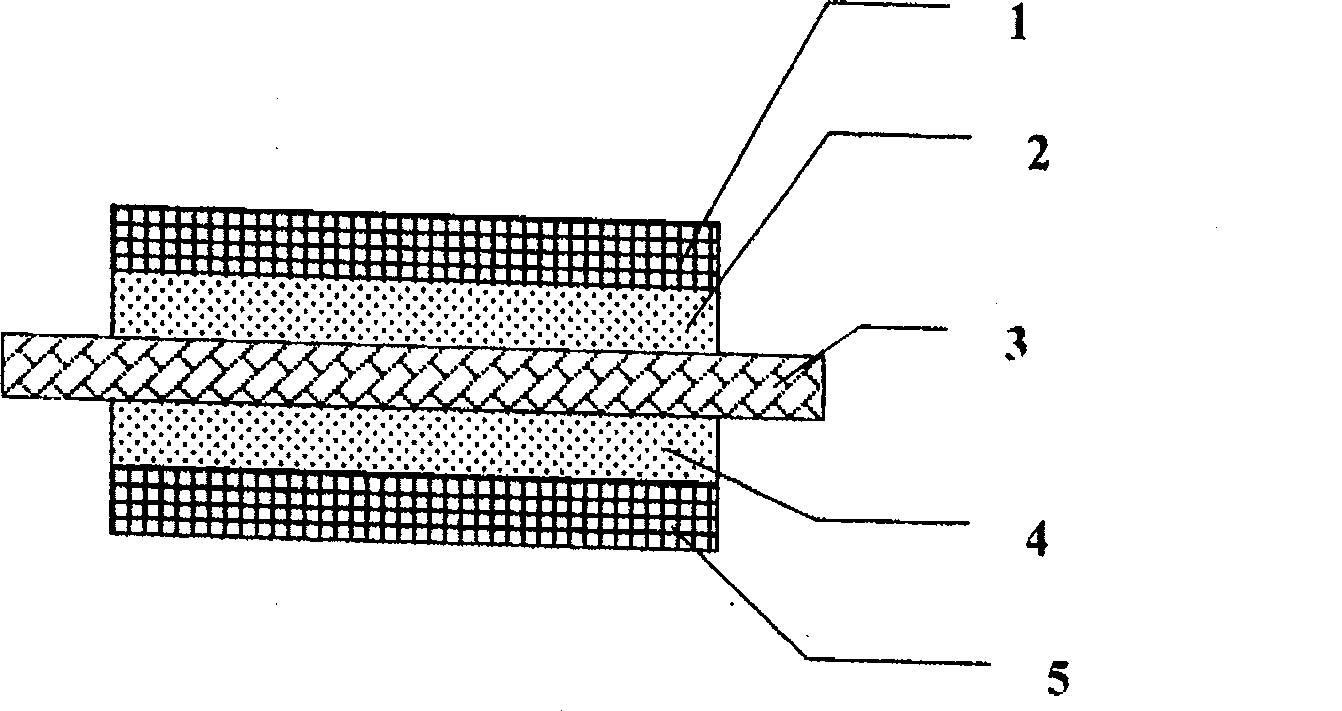

preparation example Construction

[0026] c. Preparation of leveling layer slurry. The leveling layer slurry used in the present invention uses low-carbon alcohol as the basic solvent, and the water content of the alcohol must be below 5 wt%. Weigh 5-20 parts of alcohol, add 1 part of carbon material, stir and ultrasonically disperse for several minutes, add the corresponding amount of PTFE emulsion or powder weighed in step a into the ultrasonically dispersed suspension in the liquid. Then the suspension is ground into a bright thick liquid with a colloid mill, and then 20-200 parts by weight of alcohol is added, and ultrasonically dispersed at a frequency of 40-59 kHz for 0.5-1 hour to obtain the desired ink-like liquid.

[0027] d. Coating of leveling layer. The leveling layer can be applied on the diffusion layer by brushing, scraping or spraying. The method of brushing and scraping is as follows: Use a rubber dropper to drop a few drops of the ink-like liquid obtained in step b on the diffusion layer, u...

Embodiment 1

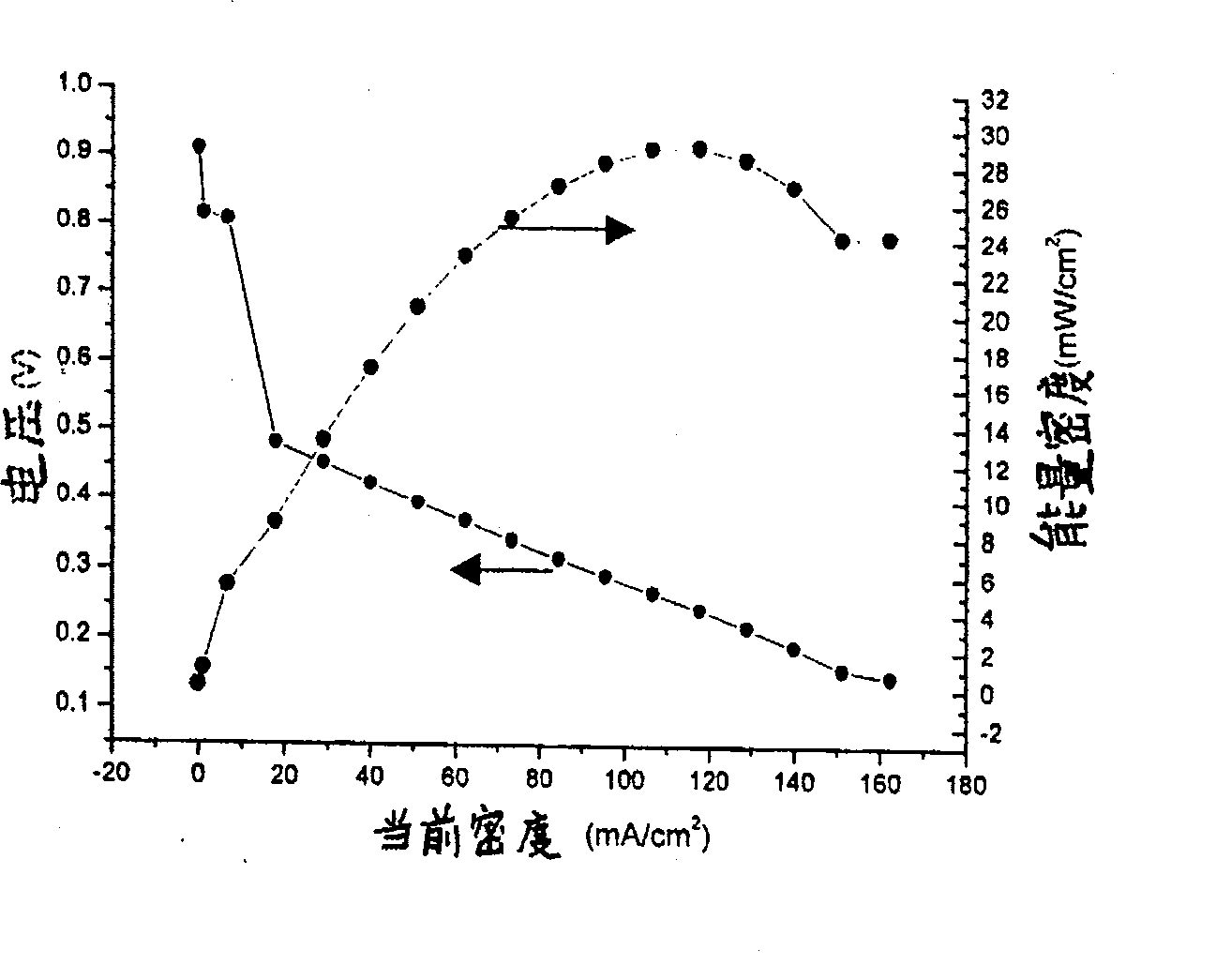

[0034] Embodiment 1: use 3wt% PTFE emulsion hydrophobization treatment carbon paper, make the mass of PTFE therein account for 10% and 30% respectively and sinter; Contain PTFE mass 10% carbon paper is anode diffusion layer, contain PTFE mass 30% is the cathode diffusion layer. Take acetylene type carbon black and 60% PTFE emulsion according to the solid mass ratio of 80:20, add 1 part of quality acetylene type carbon black in 10 parts of quality ethanol, stir and ultrasonically disperse for 3 minutes; add the weighed PTFE emulsion Then use a colloid mill to grind it into a bright liquid; add 100 parts by mass of ethanol, and ultrasonically disperse for half an hour. Use a thin PVC (polyvinyl chloride) sheet to scrape and coat the obtained ink-like liquid on the diffusion layer repeatedly, and blow it dry with a hair dryer until the load of the leveling layer is 1.5mg / cm 2 . The diffusion layer was baked at 240°C for 1 hour and then at 350°C for 2 hours. Spray the solid loa...

Embodiment 2

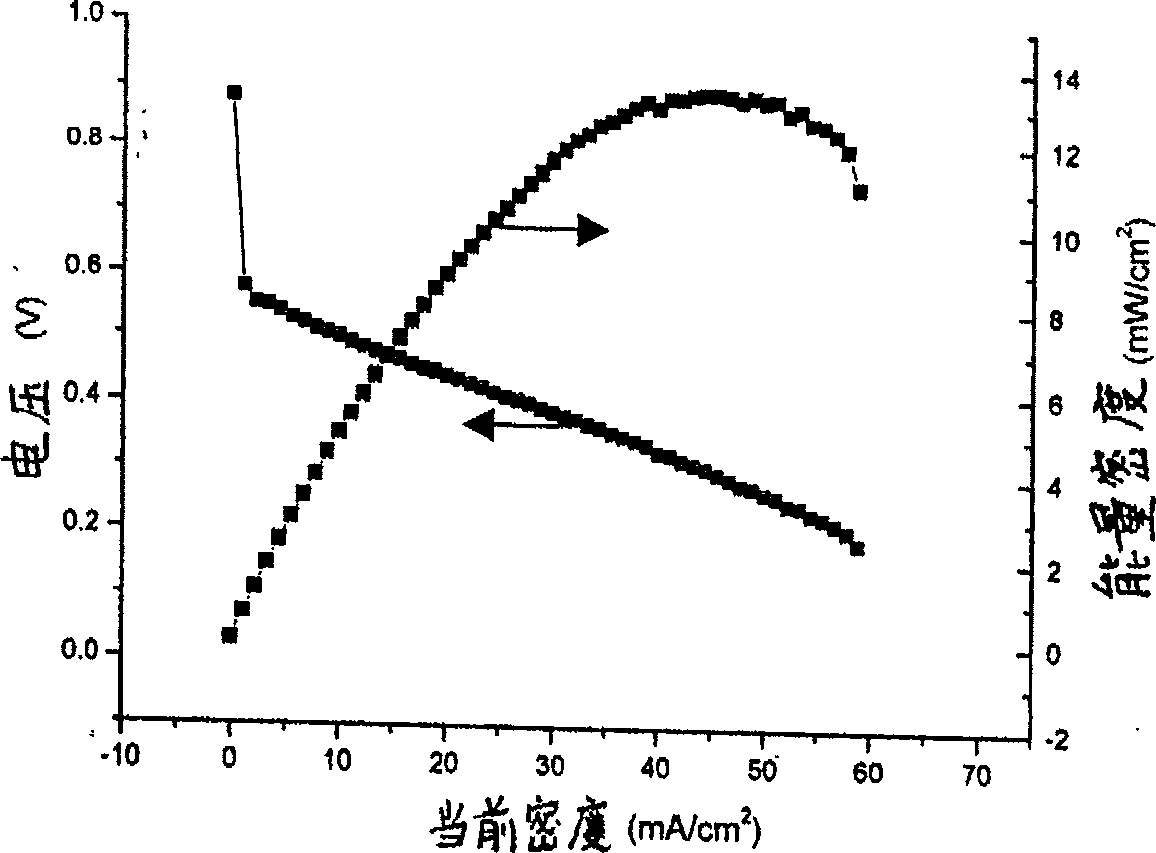

[0035] Embodiment 2: roughly as embodiment 1, just replace PTFE emulsion with PTFE powder when making leveling layer. Leveling layer load 1.2mg / cm 2 , anode PtRu / C catalyst layer metal loading 3mg / cm 2 , the cathode Pt / C catalyst layer metal loading 1mg / cm 2 . Its performance in passive direct methanol fuel cells such as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| combustion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com