Corundum silicon carbide steel fiber castable

A corundum silicon carbide steel and castable technology, applied in the field of castables, can solve the problems of large thermal stress, high cost, large temperature difference, etc., and achieve the effects of good volume stability, low cost, and good construction performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

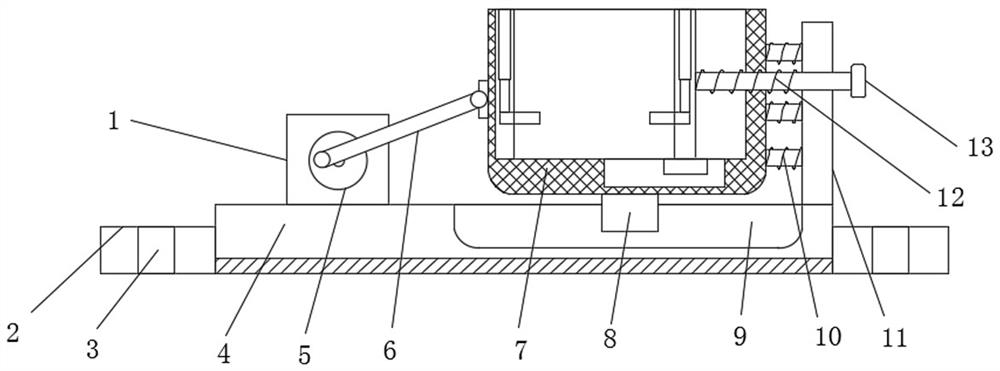

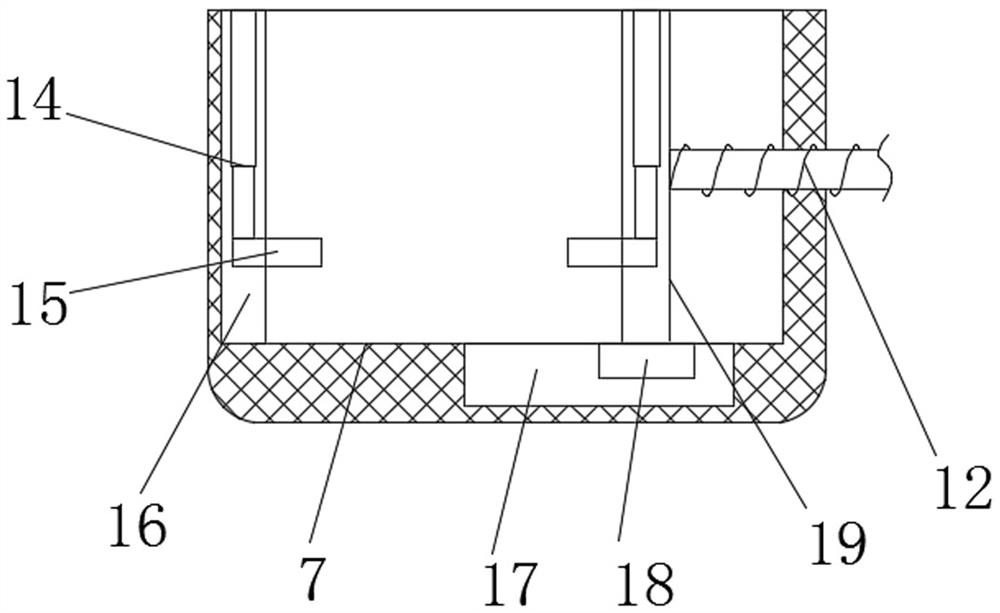

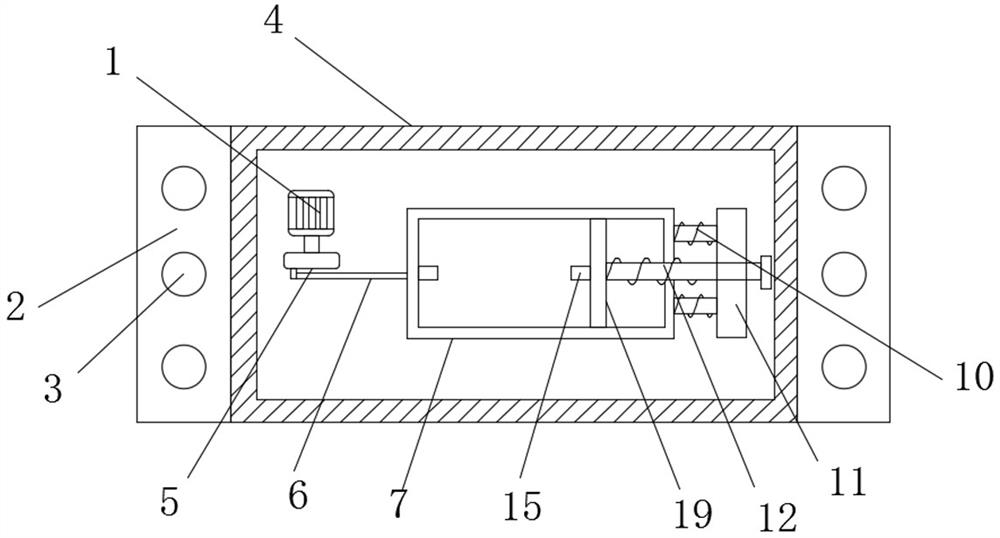

[0035] see Figure 1-3 As shown, the corundum silicon carbide steel fiber castable is prepared from the following raw materials in parts by weight: 30 parts of dense corundum, 20 parts of white corundum, 10 parts of silicon carbide, 1 part of silicon oxide micropowder, 5 parts of alumina micropowder, 1 Part of modified silica sol, 0.5 part of composite additive, 1 part of chromium oxide, 1 part of magnesium oxide, 3 parts of cement;

[0036] The castable is prepared through the following steps:

[0037]Step 1. Preparation of modified silica sol: Pour 200mL of silica sol into a 500mL three-neck flask, add ethanol and water into the mixture, the volume ratio of ethanol and water is 1:1, then ultrasonically disperse for 1 hour, and then The three-neck flask was placed in a constant temperature water bath at a temperature of 50°C. Insert an electric stirring rod, a thermometer, and a spherical condenser to raise the temperature to 90°C, add 5.18g of KH-550, and stir and react at ...

Embodiment 2

[0047] see Figure 1-3 As shown, the corundum silicon carbide steel fiber castable is prepared from the following raw materials in parts by weight: 40 parts of dense corundum, 20 parts of white corundum, 15 parts of silicon carbide, 1 part of silicon oxide micropowder, 10 parts of alumina micropowder, 5 parts Part modified silica sol, 0.5 part composite additive, 3 parts chromium oxide, 1 part magnesium oxide, 8 parts cement;

[0048] The castable is prepared through the following steps: the same as in Example 1.

Embodiment 3

[0050] see Figure 1-3 As shown, the corundum silicon carbide steel fiber castable is prepared from the following raw materials in parts by weight: 40 parts of dense corundum, 35 parts of white corundum, 15 parts of silicon carbide, 3 parts of silicon oxide micropowder, 10 parts of alumina micropowder, 5 parts 1 part of modified silica sol, 1 part of composite additive, 2 parts of chromium oxide, 2 parts of magnesia, 5 parts of cement;

[0051] The castable is prepared through the following steps: the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com