Method for producing psicose

A technique of psicose and fructose is applied in the field of preparing psicose to achieve the effects of maintaining fructose content and preventing product deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

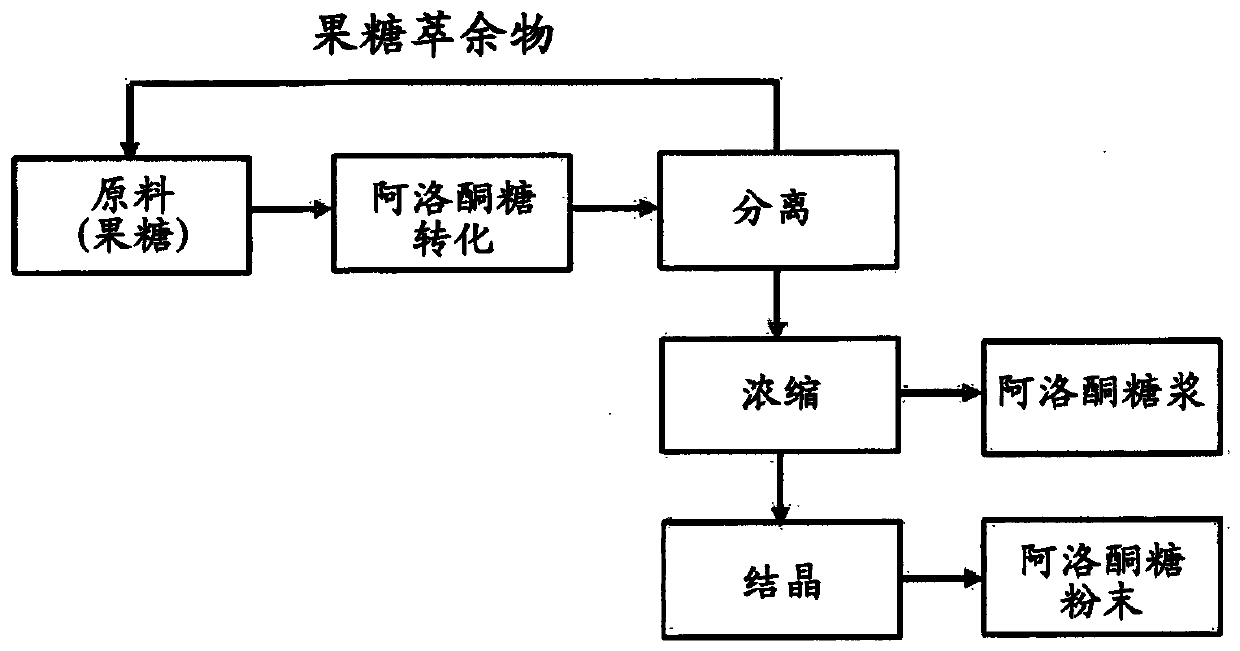

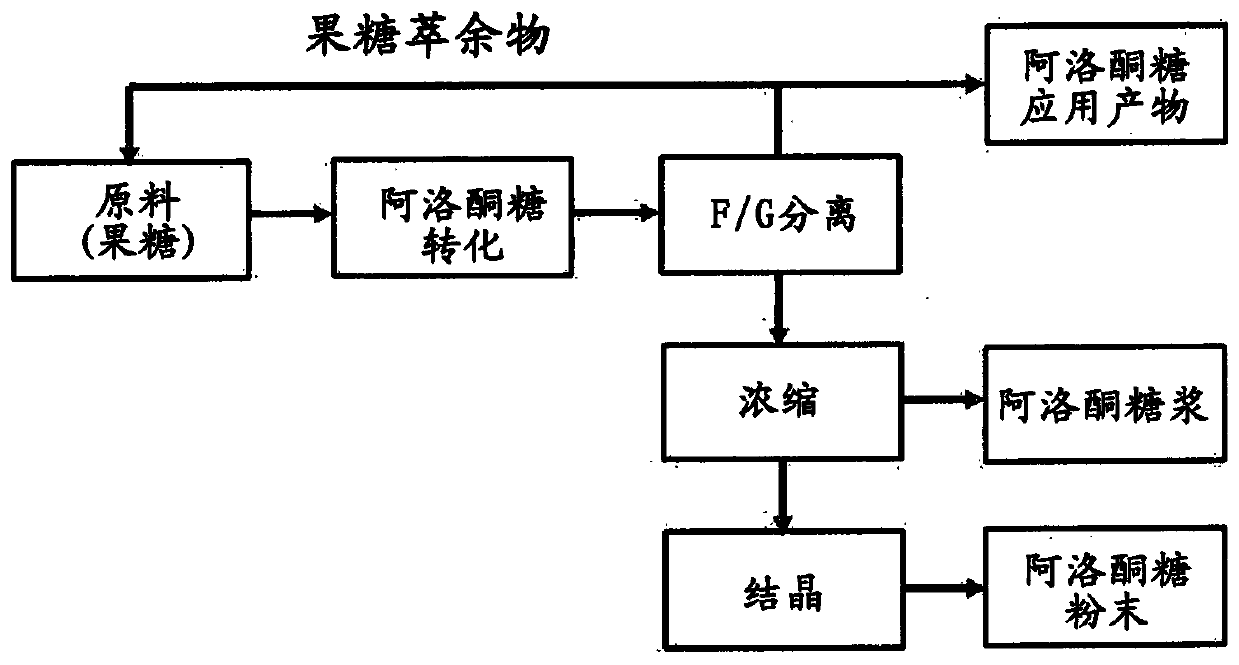

[0094] Preparation Example 1. Preparation of Allulone Syrup

[0095] Allulone syrup is prepared from a fructose substrate by a biological method substantially the same as that disclosed in Korean Laid-Open Patent Publication No. 2014-0054997.

[0096] Specifically, the gene encoding psicose epimerase (DPE gene; Gene bank: EDS06411.1) derived from Clostridiuim scindens (Clostridiuim scindens) (Clostridiuim ATCC35704) was introduced into the recombinant vector (pCES_sodCDPE) , and by using the prepared recombinant vector (pCES_sodCDPE) plasmid, Corynebacterium glutamicum was transformed by electroporation. Beads including the transformed Corynebacterium glutamicum cells were prepared and packed in an immobilization reaction column, and allulone syrup was prepared from 88% by weight fructose or 95% by weight fructose at 40 Brix. That is, 21-23 (w / w)% allulone syrup ( Allulone syrup A), and 24-26 (w / w)% allulone from a raw material containing 95% by weight fructose content of gl...

preparation example 2

[0097] Preparation example 2. Preparation of fructose raffinate

[0098] At room temperature, the two allulone syrups obtained in Preparation Example 1 were passed through a column filled with the resin at a rate of twice the volume of the ion exchange resin per hour and desalted to remove impurities such as colored components and ion groups. Graded, the resins are cation exchange resins, anion exchange resins, and mixed resins of cation and anion exchange resins.

[0099] Next, by using filled with calcium (Ca 2+ ) type ion exchange resin after the high purity psicose fraction was separated by chromatography, the remainder was collected as a raffinate. The raffinate collected from the allulone syrup (psicone syrup A) obtained from a raw material having a fructose content of 77% by weight contained 85% to 98% by weight of fructose, based on 100 parts by weight of the total solid content of sugars , 1% to 10% by weight of glucose and 1% to 5% by weight of reducing sugars.

...

Embodiment 1

[0101] Example 1. Manufacture of psicose using fructose raffinate

[0102] at 3.8m 3 / hr flow rate to perform the psicose conversion process and the separation process, by using the fructose-containing raw material solution obtained in Examples 1 and 2 with a fructose content of 88% by weight to manufacture 10 tons of psicose with a content of 95% by weight solid.

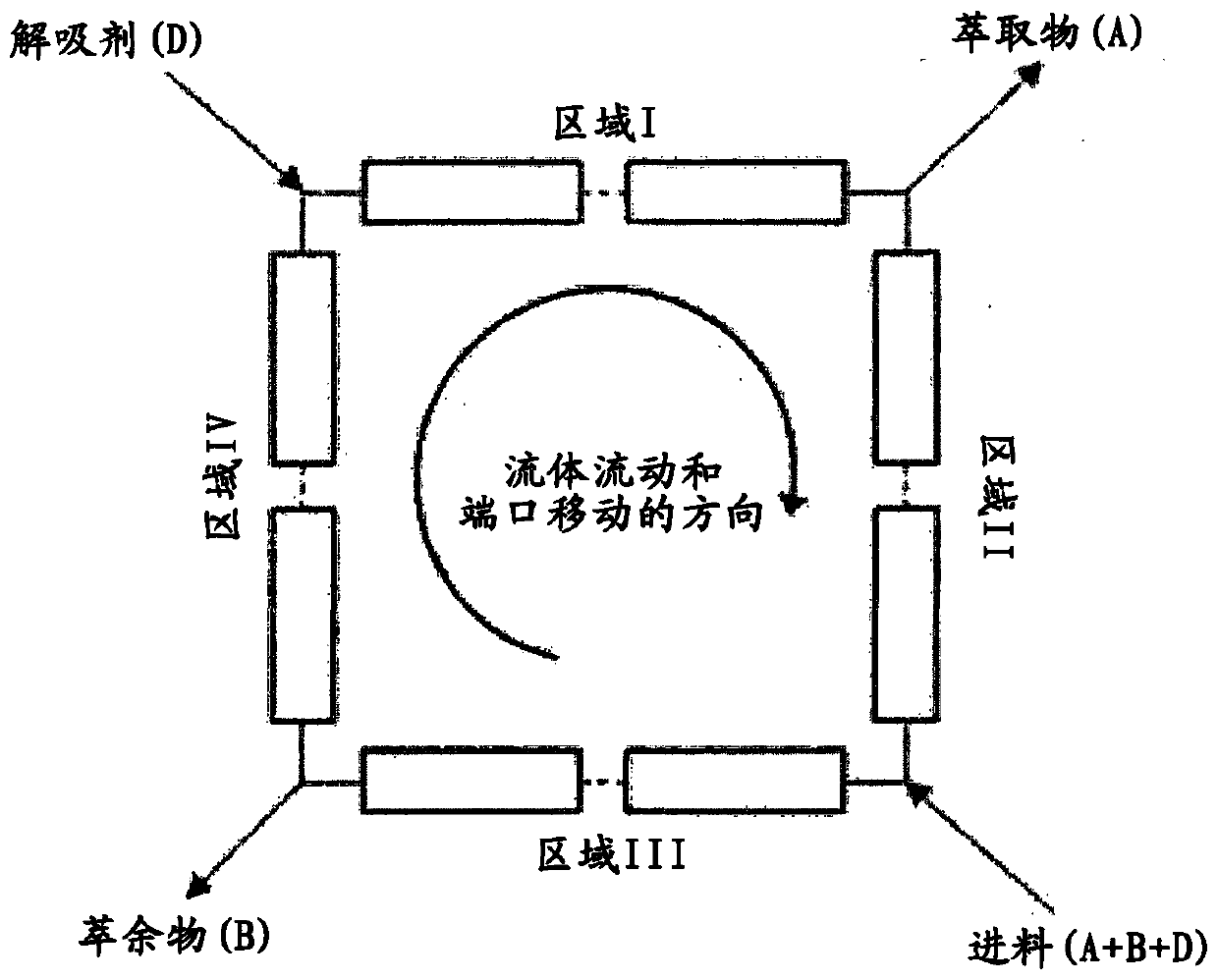

[0103] The product collected through the psicose conversion process has a psicose content of 20% to 23% by weight, and after ion purification, it is passed through the separation process at a concentration of 45% to 50% by weight. 3m per hour 3 produces a raffinate, which is produced using Ca + Type separation (SMB) resin produced during separation.

[0104] Specifically, a allulone syrup having a psicose content of 20 to 23 wt% was obtained through a psicose conversion process using a raw material substrate solution (psicose syrup A) having a fructose content of 88 wt%. The psicose conversion product passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com