Solid depilatory wax and preparation method

A depilatory wax, solid technology, applied in the field of depilatory wax, can solve the problems of unexplained or provided hair removal effect test, no hair removal effect, unsatisfactory fine hair removal, etc., to achieve excellent hair removal effect, good film formation, not easy allergic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

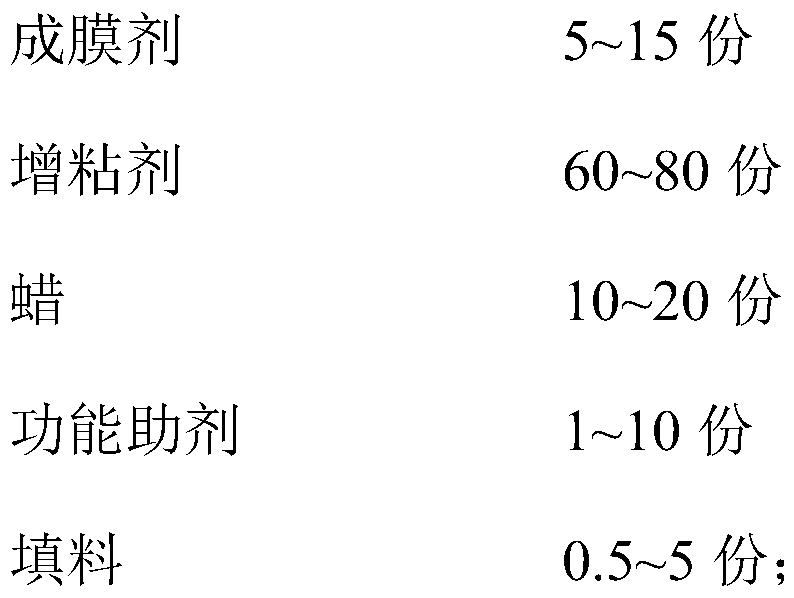

[0050] A kind of solid depilatory wax of the present embodiment is made from the following raw materials in parts by weight:

[0051]

[0052] Wherein, the functional auxiliary agent is hydrogenated coconut oil and hydrogenated styrene-butadiene block copolymer with a weight ratio of 1:12.

[0053] The film-forming agent is an ethylene-vinyl acetate copolymer and an ethylene-vinyl acetate-vinyl alcohol terpolymer with a weight ratio of 1:1.5.

[0054] The filler is mica powder, titanium dioxide and zinc oxide in a weight ratio of 1:6:1.

[0055] The tackifier is rosin resin, rosin glyceride, hydrogenated rosin glyceride and hydrogenated rosin methyl ester in a weight ratio of 35:12:5:1.

[0056] The wax is paraffin wax (54# fully refined paraffin wax) and silicon wax in a weight ratio of 5:1.

[0057] The preparation method of above-mentioned solid depilatory wax is as follows:

[0058] According to the paraffin wax, the ethylene-vinyl acetate copolymer, the ethylene-vin...

Embodiment 2

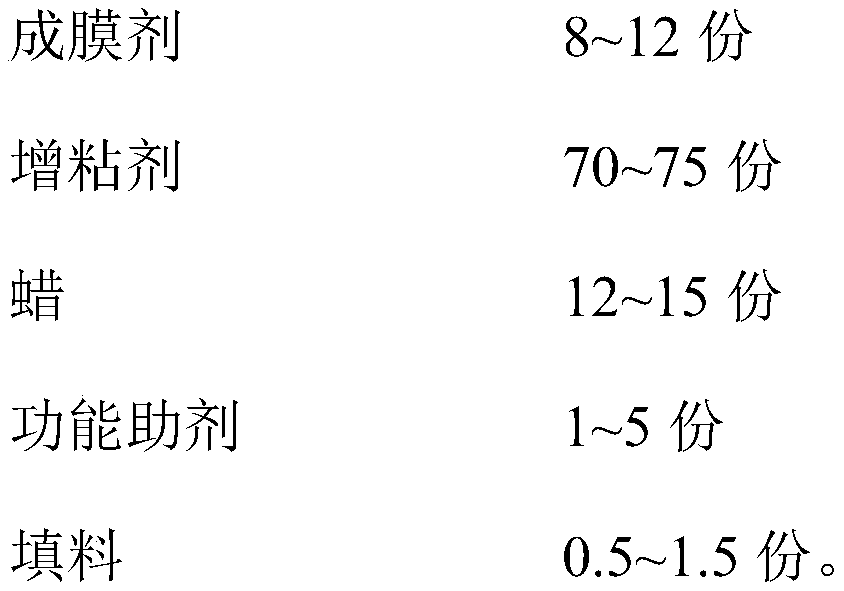

[0060] A kind of solid depilatory wax of the present embodiment is made from the following raw materials in parts by weight:

[0061]

[0062] Wherein, the functional auxiliary agent is hydrogenated coconut oil and hydrogenated styrene-butadiene block copolymer with a weight ratio of 1:12.

[0063] The film-forming agent is an ethylene-vinyl acetate copolymer and an ethylene-vinyl acetate-vinyl alcohol terpolymer with a weight ratio of 1:1.5.

[0064] The filler is mica powder, titanium dioxide and zinc oxide in a weight ratio of 1:6:1.

[0065] The tackifier is rosin resin, rosin glyceride, hydrogenated rosin glyceride and hydrogenated rosin methyl ester in a weight ratio of 35:12:5:1.

[0066] The wax is paraffin wax (54# fully refined paraffin wax) and silicon wax in a weight ratio of 5:1.

[0067] The preparation method of above-mentioned solid depilatory wax is as follows:

[0068] According to the paraffin wax, the ethylene-vinyl acetate copolymer, the ethylene-vin...

Embodiment 3

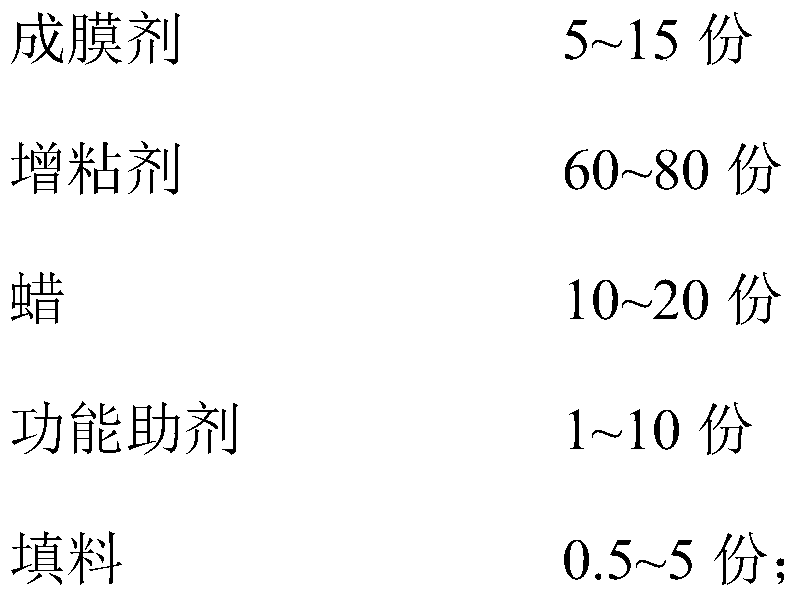

[0070] A kind of solid depilatory wax of the present embodiment is made from the following raw materials in parts by weight:

[0071]

[0072] Wherein, the functional auxiliary agent is hydrogenated coconut oil and hydrogenated styrene-butadiene block copolymer with a weight ratio of 1:12.

[0073] The film-forming agent is an ethylene-vinyl acetate copolymer and an ethylene-vinyl acetate-vinyl alcohol terpolymer with a weight ratio of 1:1.5.

[0074] The filler is mica powder, titanium dioxide and zinc oxide in a weight ratio of 1:6:1.

[0075] The tackifier is rosin resin, rosin glyceride, hydrogenated rosin glyceride and hydrogenated rosin methyl ester in a weight ratio of 35:12:5:1.

[0076] The wax is paraffin wax (54# fully refined paraffin wax) and silicon wax in a weight ratio of 5:1.

[0077] The preparation method of above-mentioned solid depilatory wax is as follows:

[0078] According to the paraffin wax, the ethylene-vinyl acetate copolymer, the ethylene-vin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com