Preparation method of polyacid intercalation 3D-LDHs photo-Fenton catalyst

A catalyst, acid intercalation technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve harsh preparation conditions, incomplete organic matter mineralization, etc. The problem is to achieve the effect of simple preparation method, improved light energy utilization rate, high mechanical strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

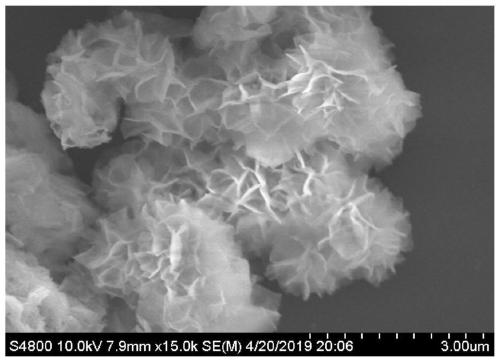

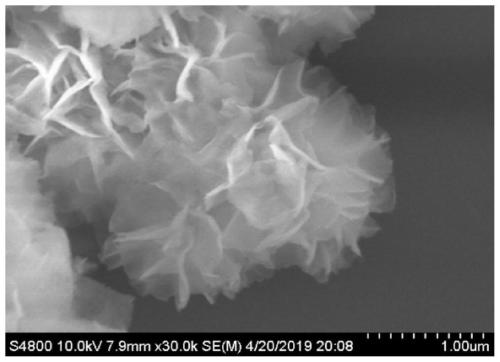

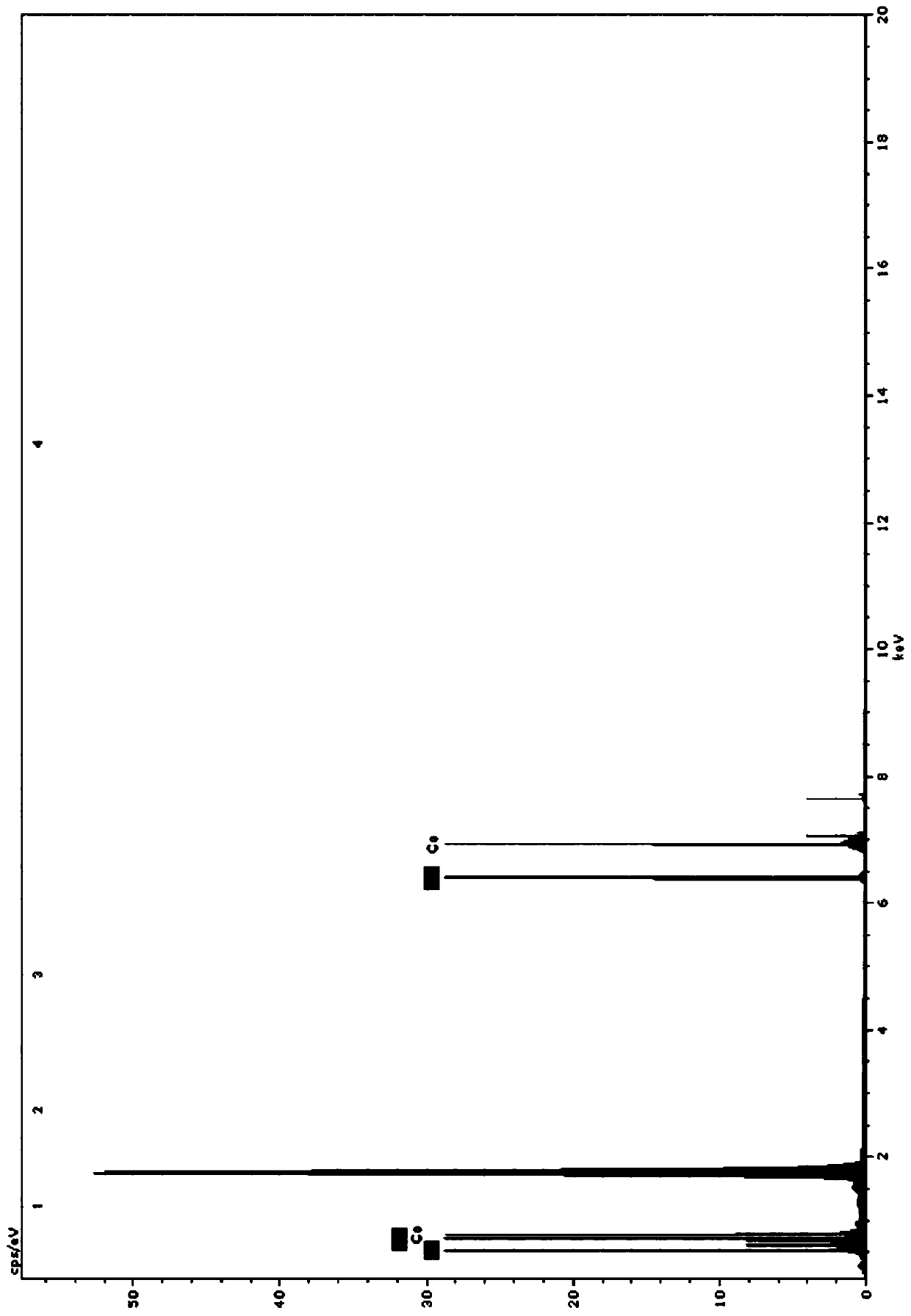

[0051] Specific embodiment 1: The preparation method of multi-acid intercalation binary 3D-LDHs photo-Fenton catalyst in this embodiment is carried out according to the following steps:

[0052] 1. Mix 12-18mmol Co(NO 3 ) 2 ·6H 2 O or Ni(NO 3 ) 2 ·6H 2 O, 6mmol Fe(NO 3 ) 3 9H 2 O, 42mmol urea, 0.2g NH 4 F and 0.2mol Tris solution, dissolved in 60mL organic solvent at room temperature and stirred for 2 hours, then transferred the solution into a 100mL autoclave, and sealed the autoclave at 120-150°C for 10-14 hours, using a membrane filter The gel was isolated by vacuum filtration, and the gel was redispersed in 100 mL of 0.5 mol / L Na2 CO 3 Stir in the solution for 1 hour, wash twice with deionized water and dry in an oven at 80-120°C for 10 hours to obtain the sample;

[0053] 2. Take the sample prepared in step 1 and disperse it in PMo with a concentration of 0.02-0.08mol / L according to the concentration of 2mg / mL 10 or CoW 12 solution, and then stirred at room te...

specific Embodiment approach 2

[0054] Embodiment 2: This embodiment is different from Embodiment 1 in that the organic solvent described in step 1 is anhydrous methanol, absolute ethanol or ethylene glycol. Others are the same as the first embodiment.

specific Embodiment approach 3

[0055] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that in step 1, the autoclave is sealed at 150° C. for 10 hours. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com