Preparation method of 6-gingerol

A technology of gingerol and ethanol, which is applied in the field of preparation of 6-gingerol, can solve problems such as the difficulty in mass production and preparation, difficulty in separation and purification of 6-gingerol, and lack of market prospects, and achieve convenient segment identification and shortened elution The effect of time and purification effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The present embodiment is the preparation method of high-purity 6-gingerol, and the steps are as follows:

[0050] (1) Ethanol pretreatment: Weigh 100 g of ginger resin (6-gingerol content is 34.77%), add it to 1000 mL of 95% (volume fraction) ethanol, stir and dissolve at room temperature. After the ginger resin is completely dissolved, add water to the solution while homogenizing, add 730 mL of water within 1 hour to adjust the volume fraction of ethanol to about 55%, and obtain a yellow ginger resin ethanol emulsion.

[0051] (2) Cooling and impurity removal: Cool the above-mentioned ginger resin ethanol emulsion at 0-5°C for 12 hours to precipitate a brown precipitate, then place it at room temperature and allow it to warm up to room temperature naturally, and the precipitate gradually melts into a dark brown oily liquid , then remove the dark brown oily liquid in the lower layer through liquid separation, keep the light yellow and clear ethanol solution of ginger r...

Embodiment 2-5

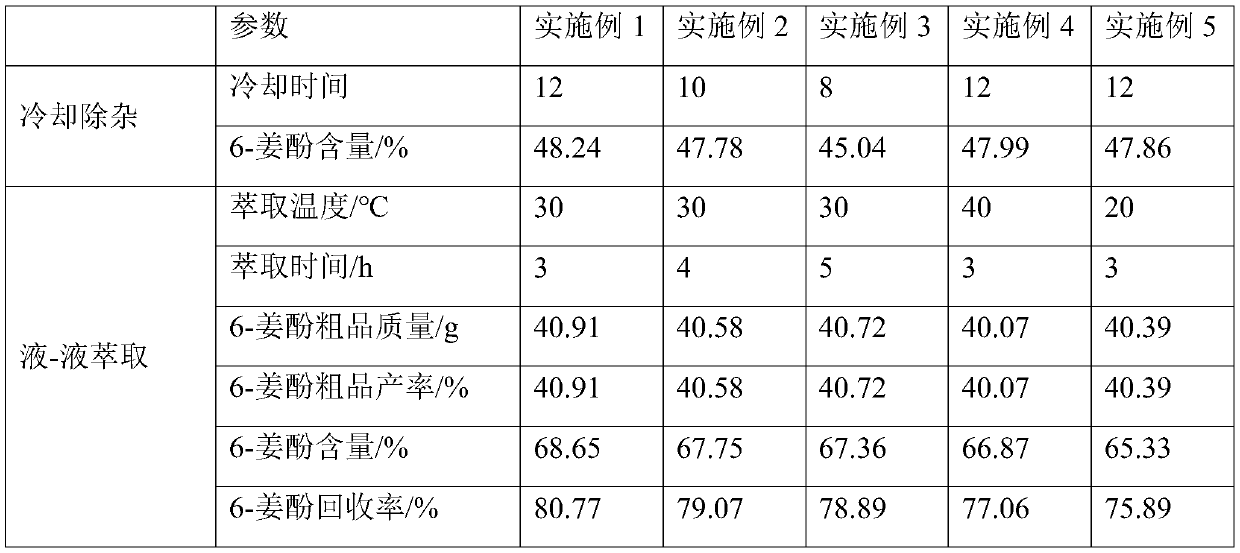

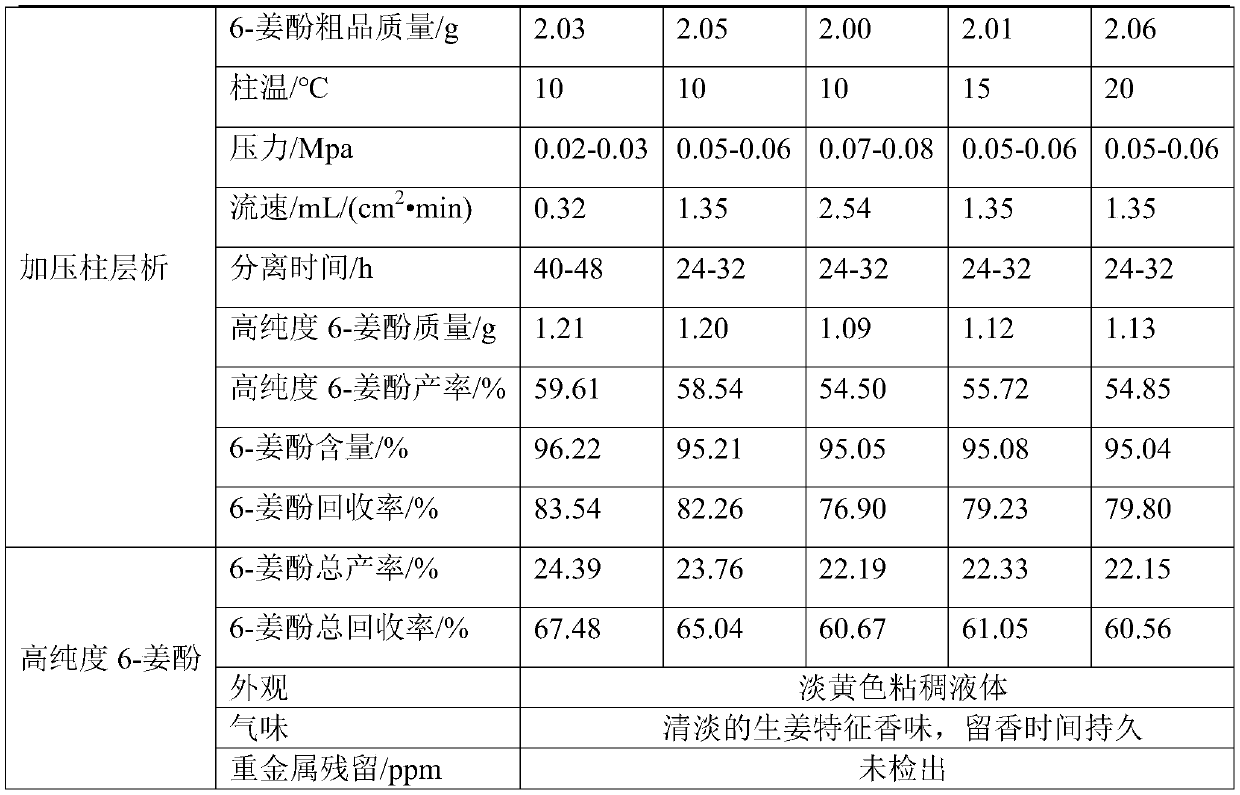

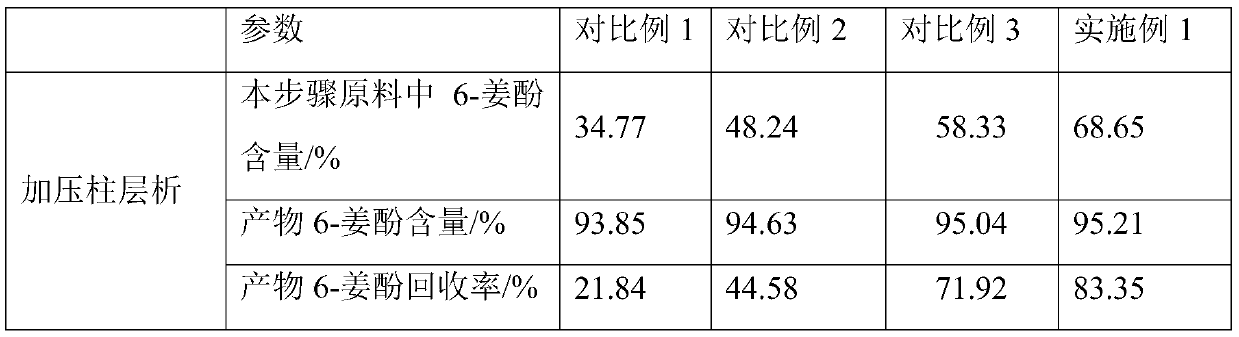

[0055] Embodiment 2-5 is the preparation method of high-purity 6-gingerol, with reference to the preparation method of embodiment 1 high-purity 6-gingerol, part parameter conditions are as shown in Table 1, all the other steps are identical with embodiment 1. In addition, the test results of Examples 1-5 are also shown in Table 1.

[0056] Table 1

[0057]

[0058]

[0059] As can be seen from Table 1, the ginger resin with a 6-gingerol content of 34.77% is used as a raw material, and after cooling and removal of impurities, a ginger resin ethanol solution is obtained, and an appropriate amount of sample is taken to concentrate and dewater and then detect the content of 6-gingerol by HPLC , 6-gingerol content is increased to 45%-50%; Then utilize liquid-liquid extraction, obtain 6-gingerol crude product, 6-gingerol content further improves to 65%-70%, at this moment, 6-gingerol The productive rate of crude product is about 40%, and the rate of recovery of 6-gingerol is ...

Embodiment 6

[0071] Referring to the preparation method of embodiment 1 high-purity 6-gingerol. Embodiment 6 carries out scale-up test.

[0072] (1) Ethanol pretreatment: Weigh 1000 g ginger resin (6-gingerol content is 34.77%), add in 10.0 L of 95% (volume fraction) ethanol, stir and dissolve at room temperature. After the ginger resin is completely dissolved, add water to the solution while homogenizing, add 7.3L of water within 1 hour to adjust the ethanol volume fraction to about 55%, and obtain a yellow ginger resin ethanol emulsion.

[0073] (2) Cooling to remove impurities: Cool the above-mentioned ginger resin ethanol emulsion at 0-5°C for 12 hours to precipitate a brown precipitate, then let it stand at room temperature and allow it to warm up to room temperature naturally, and the precipitate gradually melts into a dark brown oily liquid. Then remove the dark brown oily liquid of the lower floor through liquid separation, keep the light yellow clear ginger resin ethanol solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com