Yellowing resistant and waterborne epoxy hardener and preparation technology thereof

A water-based epoxy and anti-yellowing technology, which is applied in the field of curing agent, can solve the problems of yellowing of cured film and poor application effect, and achieve the effects of improved anti-yellowing performance, improved quality, and good application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

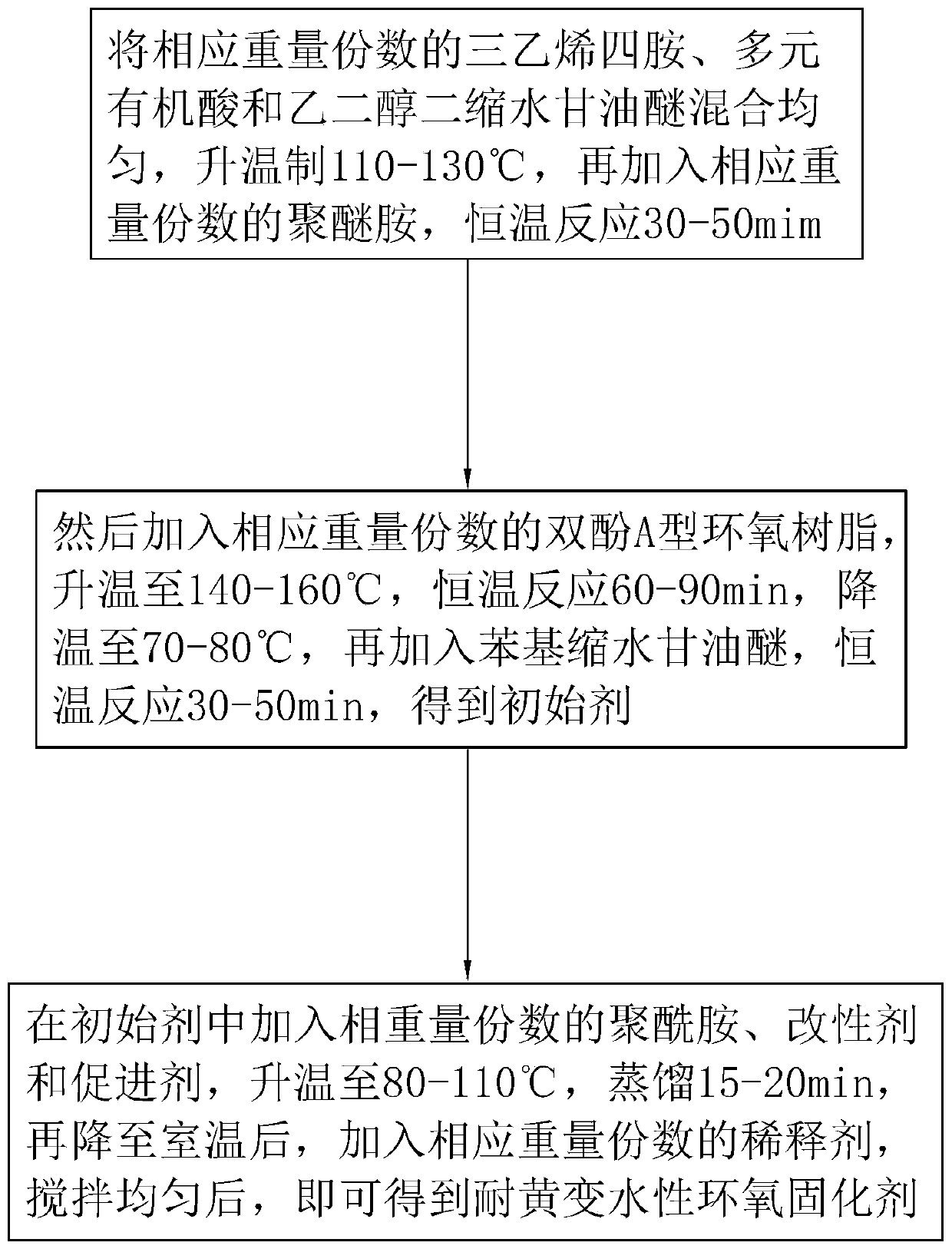

[0043] Embodiment 1: A kind of anti-yellowing water-based epoxy curing agent, each component and its corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0044] Step 1: Mix the corresponding parts by weight of triethylenetetramine, dimer acid and ethylene glycol diglycidyl ether evenly, raise the temperature to 120°C, then add the corresponding parts by weight of polyetheramine, and react at a constant temperature of 40 min;

[0045] Step 2, then add bisphenol A epoxy resin in corresponding parts by weight, heat up to 150°C, react at a constant temperature for 75 minutes, cool down to 75°C, add phenyl glycidyl ether, react at a constant temperature for 40 minutes, and obtain the initial agent;

[0046] Step 3: Add polyamide, polyamide resin, and triethanolamine in parts by weight to the initial agent, raise the temperature to 95°C, distill for 17.5 minutes, and then cool down to room temperature, add ethanol in parts by weight, and...

Embodiment 2-8

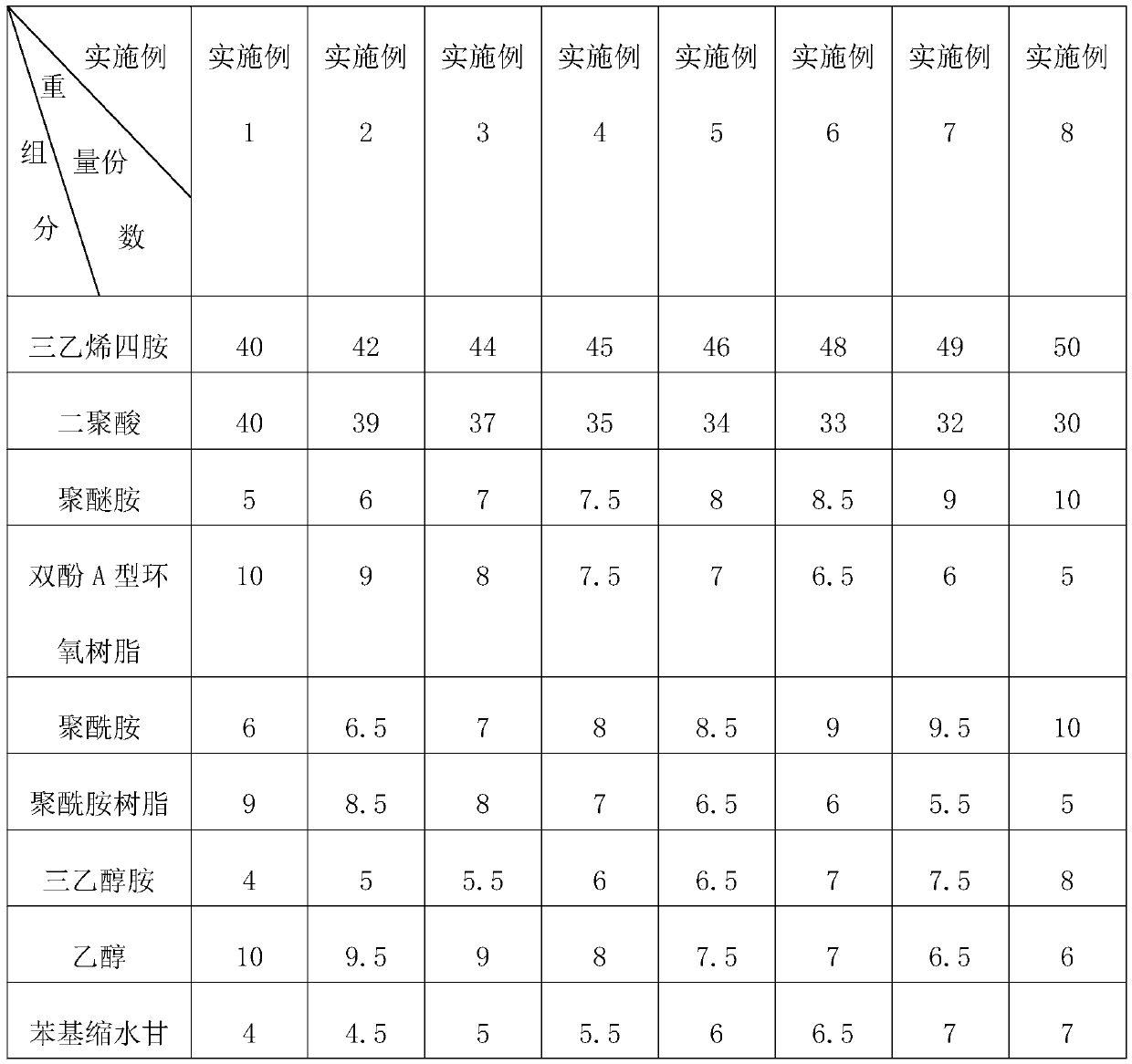

[0047] Example 2-8: A yellowing-resistant water-based epoxy curing agent, the difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

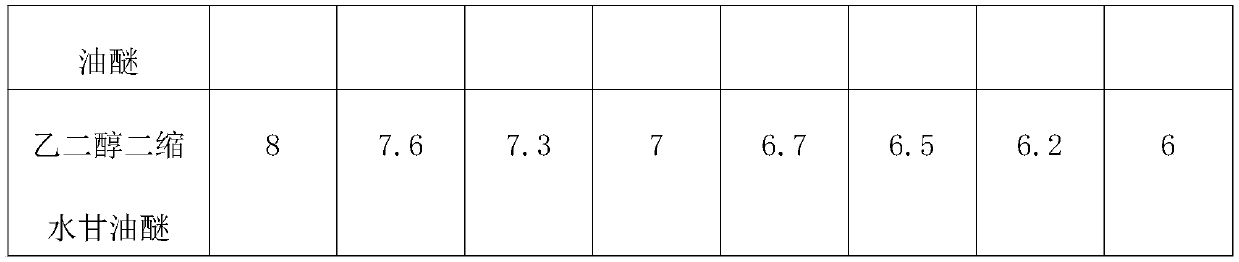

[0048] Each component and parts by weight thereof in table 1 embodiment 1-8

[0049]

[0050]

Embodiment 9

[0051] Embodiment 9: A kind of anti-yellowing water-based epoxy curing agent, the difference from Example 1 is that step one is specifically set as, the corresponding parts by weight are 40 parts of triethylenetetramine, 40 parts of benzoic acid Mix evenly with 8 parts of ethylene glycol diglycidyl ether, raise the temperature to 120°C, then add corresponding parts by weight of polyetheramine, and react at a constant temperature of 40mim.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com