Heat-conducting flame-retardant epoxy resin composite material and preparation method thereof

A composite material and epoxy resin technology, applied in the field of composite materials, can solve the problems of poor thermal conductivity and flame retardant performance, affecting the processing performance and mechanical properties of epoxy resin matrix, to improve thermal conductivity, solve low thermal conductivity, To achieve the effect of uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

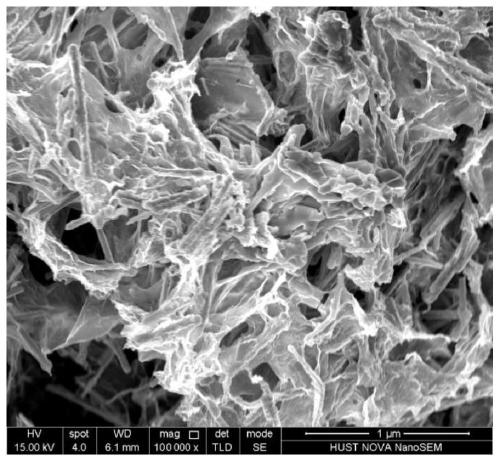

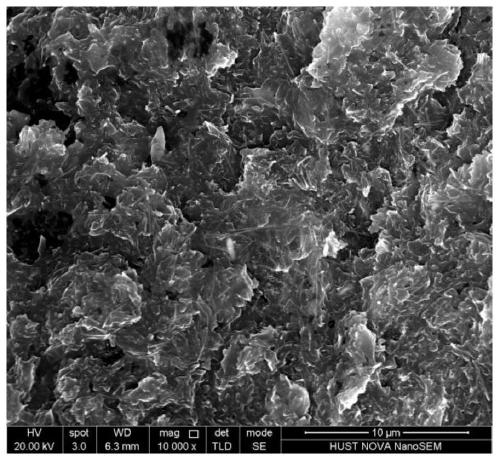

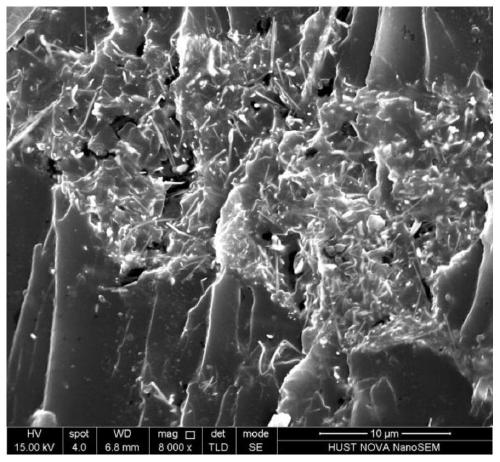

[0044] An epoxy resin / reduced graphene oxide-silver nanowire airgel composite coated with molybdenum disulfide with thermal conductivity and flame retardancy. This composite material includes an epoxy resin matrix material, and a reduced graphene oxide-silver nanowire aerogel coated with molybdenum disulfide. The aspect ratio of the silver nanowire is 100; in the reduced graphene oxide-silver nanowire airgel coated with molybdenum disulfide, the gas condensation of molybdenum disulfide and the reduced graphene oxide-silver nanowire The mass ratio of colloid is 1:4; in the reduced graphene oxide-silver nanowire airgel, the mass ratio of reduced graphene oxide to silver nanowire is 1:5; the epoxy resin matrix is bisphenol A-type epoxy resin, the reduced graphene oxide-silver nanowire airgel coated with molybdenum disulfide, its addition ratio is 2vol% by volume.

[0045] The preparation method of the reduced graphene oxide-silver nanowire airgel composite material coated with...

Embodiment 2

[0053] An epoxy resin / reduced graphene oxide-silver nanowire airgel composite coated with molybdenum disulfide with thermal conductivity and flame retardancy. This composite material includes an epoxy resin matrix material, and a reduced graphene oxide-silver nanowire aerogel coated with molybdenum disulfide. The aspect ratio of the silver nanowire is 200; in the reduced graphene oxide-silver nanowire airgel coated with molybdenum disulfide, the gas condensation of molybdenum disulfide and the reduced graphene oxide-silver nanowire The mass ratio of colloid is 1:4; in the reduced graphene oxide-silver nanowire airgel, the mass ratio of reduced graphene oxide to silver nanowire is 1:10; the epoxy resin matrix is bisphenol Type A epoxy resin, the reduced graphene oxide-silver nanowire airgel coated with molybdenum disulfide, its addition ratio is 4vol% by volume.

[0054] The preparation method of the reduced graphene oxide-silver nanowire airgel composite material coated wit...

Embodiment 3

[0062] An epoxy resin / reduced graphene oxide-silver nanowire airgel composite coated with molybdenum disulfide with thermal conductivity and flame retardancy. This composite material includes an epoxy resin matrix material, and a reduced graphene oxide-silver nanowire aerogel coated with molybdenum disulfide. The aspect ratio of the silver nanowire is 200; in the reduced graphene oxide-silver nanowire airgel coated with molybdenum disulfide, the gas condensation of molybdenum disulfide and the reduced graphene oxide-silver nanowire The mass ratio of colloid is 1:2; in the reduced graphene oxide-silver nanowire airgel, the mass ratio of reduced graphene oxide to silver nanowire is 1:4; the epoxy resin matrix is bisphenol F-type epoxy resin, the reduced graphene oxide-silver nanowire airgel coated with molybdenum disulfide, its addition ratio is 1vol% by volume.

[0063] The preparation method of the reduced graphene oxide-silver nanowire airgel composite material coated with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com