Production technology for promoting acid resistance of double caramel color

A technology of double caramel and production process, which is applied to the functions of food ingredients, azo dyes, organic dyes, etc. It can solve the problems of precipitation and suspension, poor acid resistance of double caramel color, and affect the quality of beverages, so as to overcome environmental protection , Improve the effect of acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

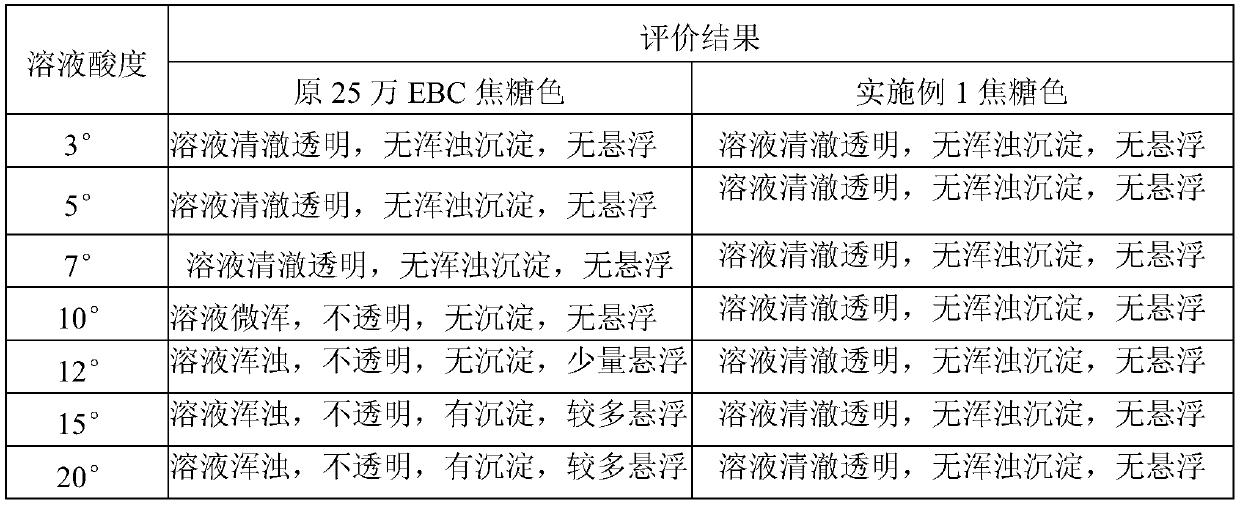

Embodiment 1

[0034] The present invention is a production process for improving the acid resistance of double caramel color, comprising the following steps:

[0035] 1), raw material metering concentration: the dry matter is 6000kg DE value of 97% glucose syrup is metered into the reaction tank, and concentrated to dry basis is 60%;

[0036] 2), a catalyzer: add sodium sulfite 120kg, ammonium sulfite 60kg in the already concentrated glucose syrup, open and stir and mix well;

[0037] 3), pressurized reaction for the first time: the above-mentioned syrup added with the catalyst is pressurized and heated up in the reaction tank, and the pressure gauge pressure in the reaction process control tank is 0.4Mpa, and the temperature in the tank is 150 ℃, and sampling is detected every 30 minutes. Its color rate, when the color rate is 0.190 (converted to EBC unit is 0.190÷0.076×20000=50000EBC, the same below) terminates a reaction;

[0038] 4), secondary catalyst: add 120kg of liquefied ammonia t...

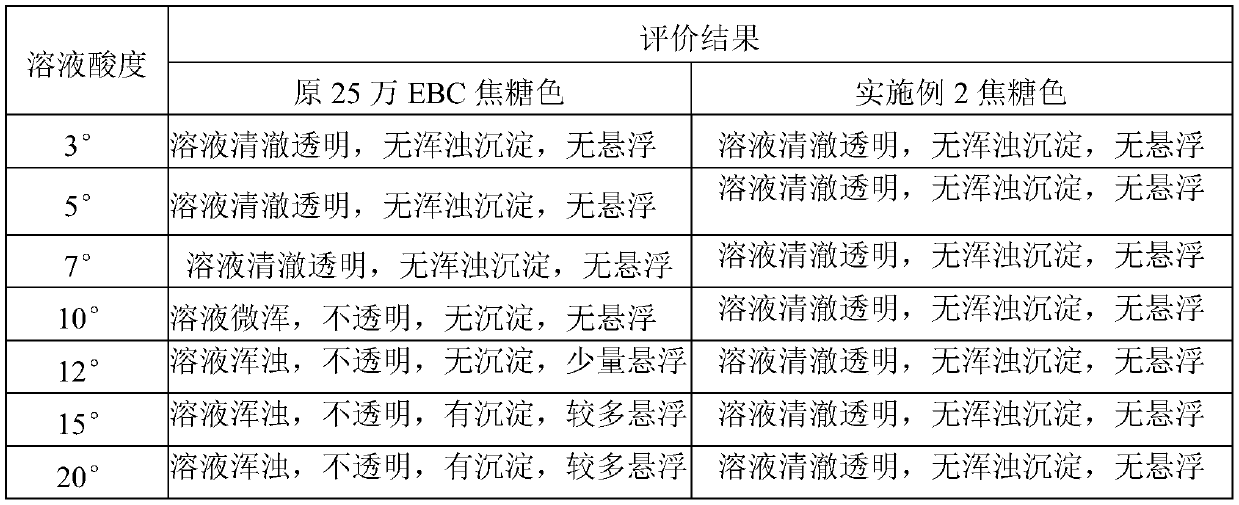

Embodiment 2

[0049] A process technology for improving the acid resistance of double caramel color, comprising the following steps:

[0050]1), raw material metering concentration: the dry matter is 6000kg DE value of 97% glucose syrup is metered into the reaction tank, and concentrated to dry basis is 60%;

[0051] 2), a catalyst: add sodium sulfite (according to the ratio recorded in the claims, the amount of the first catalyst should be 3~5% of the raw material) 180kg, 120kg of ammonium sulfite in the concentrated glucose syrup, open and stir fully mix;

[0052] 3), pressurized reaction for the first time: the above-mentioned syrup added with the catalyst is pressurized and heated up in the reaction tank, and the pressure gauge pressure in the reaction process control tank is 0.4Mpa, and the temperature in the tank is 150 ℃, and sampling is detected every 30 minutes. Its color rate, when the color rate is 0.190 (converted to EBC unit is 0.190÷0.076×20000=50000EBC, the same below) termi...

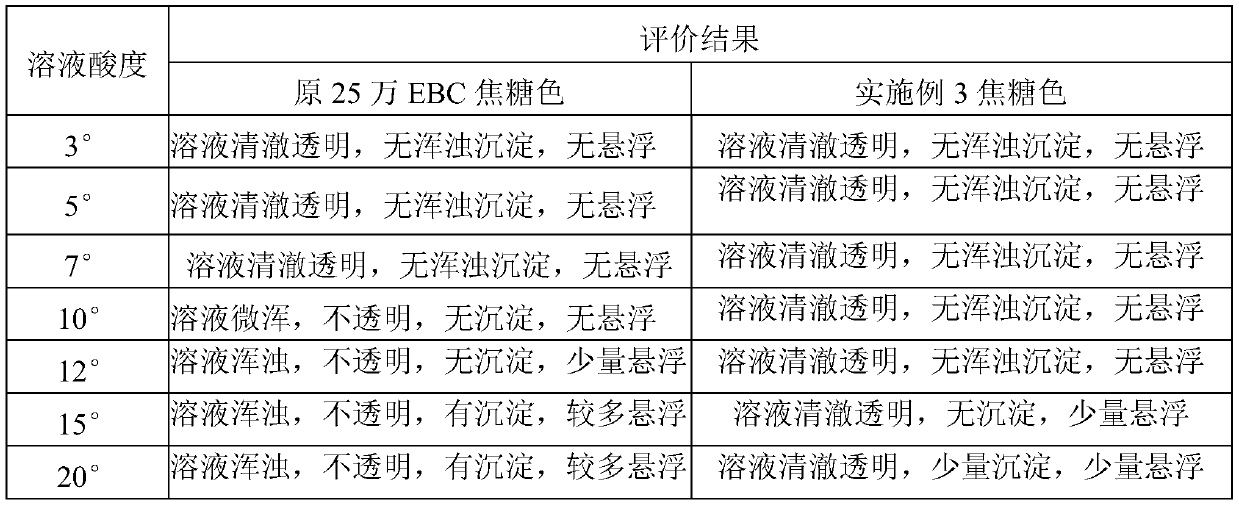

Embodiment 3

[0063] A process technology for improving the acid resistance of double caramel color, comprising the following steps:

[0064] 1), raw material metering concentration: the dry matter is 6000kg DE value of 97% glucose syrup is metered into the reaction tank, and concentrated to dry basis is 60%;

[0065] 2), a catalyzer: add sodium sulfite 140kg, ammonium sulfite 80kg in the already concentrated glucose syrup, open and stir and mix well;

[0066] 3), pressurized reaction for the first time: the above-mentioned syrup added with the catalyst is pressurized and heated up in the reaction tank, and the pressure gauge pressure in the reaction process control tank is 0.4Mpa, and the temperature in the tank is 150 ℃, and sampling is detected every 30 minutes. Its color rate, when the color rate is 0.190 (converted to EBC unit is 0.190÷0.076×20000=50000EBC, the same below) terminates a reaction;

[0067] 4), secondary catalyst: add 120kg of liquefied ammonia to the raw material of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com