Environment-friendly shell powder coating and processing process thereof

A processing technology and technology of shell powder, applied in the field of environmental protection shell powder coating and its processing technology, can solve problems such as inability to guarantee environmental health and safety, human harm, etc., and achieve the effects of prolonging normal service life, improving quality, and accelerating purification speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

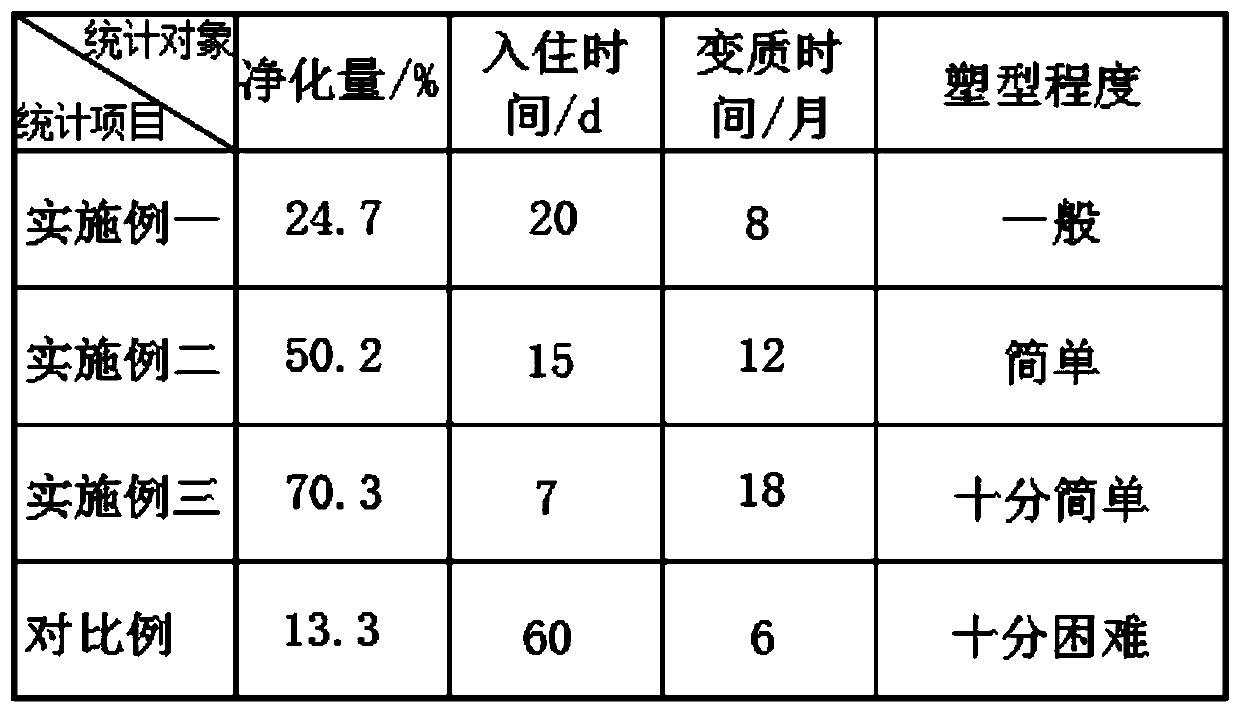

Examples

Embodiment 1

[0031] Step 1. Material pretreatment: select the cleaned pearls and waste shells, dry them in a ventilated place for a period of time, then calcinate the pearls and shells at high temperature, then grind them, and then screen out 80 parts of shell powder through an 800-mesh sieve ;

[0032] Step 2. Production of stock solution: inject 120 parts of water into the blender, add 80 parts of shell powder and 4 parts of deodorizing agent, and stir for 1 hour at a speed of 350 r / min to obtain raw material A;

[0033] Step 3, effect enhancement: add 1 part of enhancer and 3 parts of ammonium dihydrogen phosphate to the raw material A prepared in step 2, stir at a speed of 300 r / min for 0.5 h, and obtain raw material B;

[0034] Step 4: Congealing type preparation: Add 10 parts of Tianzhu fiber and 8 parts of glutinous rice flour to the raw material B prepared in Step 3, stir at a speed of 300r / min for 0.6h, put it into a sealed tank, and obtain a finished product.

Embodiment 2

[0036] Step 1. Material pretreatment: select the cleaned pearls and waste shells, dry them in a ventilated place for a period of time, then calcinate the pearls and shells at high temperature, then grind them, and then screen 90 parts of shell powder through an 800-mesh sieve ;

[0037] Step 2. Production of stock solution: inject 130 parts of water into the blender, add 90 parts of shell powder and 5 parts of deodorizing agent, and stir for 1.5 hours at a speed of 300 r / min to obtain raw material A;

[0038] Step 3, effect enhancement: Add 2 parts of enhancer and 4 parts of ammonium dihydrogen phosphate to the raw material A prepared in step 2, stir at a speed of 300r / min for 0.6h, and obtain raw material B;

[0039] Step 4: Congealing preparation: Add 15 parts of Tianzhu fiber and 9 parts of glutinous rice flour to the raw material B prepared in Step 3, stir at 200 r / min for 1 hour, put it into a sealed tank, and obtain a finished product.

Embodiment 3

[0041] Step 1. Material pretreatment: select the cleaned pearls and waste shells, dry them in a ventilated place for a period of time, then calcinate the pearls and shells at high temperature, then grind them, and then screen 100 parts of shell powder through an 800-mesh sieve ;

[0042] Step 2. Production of stock solution: inject 150 parts of water into the blender, add 100 parts of shell powder and 6 parts of deodorizing agent, and stir for 2 hours at a speed of 200 r / min to obtain raw material A;

[0043] Step 3, effect enhancement: Add 3 parts of enhancer and 5 parts of ammonium dihydrogen phosphate to the raw material A prepared in step 2, stir at a speed of 250r / min for 0.8h, and obtain raw material B;

[0044] Step 4, preparation of congealed form: Add 20 parts of Tianzhu fiber and 10 parts of glutinous rice flour to the raw material B prepared in Step 3, stir at a speed of 150r / min for 1.5h, put it into a sealed tank, and obtain a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com