Tunnel illumination lamps and tunnel illumination system capable of improving visual range

A technology for tunnel lighting and tunnel lighting, which is applied in outdoor lighting, lighting devices, fixed lighting devices, etc. It can solve problems such as discontinuous spectral wavelength of lamps, impact on driving safety, high brightness and short viewing distance, etc., to achieve the elimination of glare problems, Improve illumination uniformity and reduce the effect of black holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation method of the above-mentioned luminescent material is:

[0020] 1. Mix the above raw materials according to M (1-x-y-z) Al 2 o 4 :xEu 2+ , 2xDy, yR 3+ , zCe 3+ Measuring ratio firing into crystal structure, x value is 0.005-0.03, y+z value is 0.01-0.06, z value is 0.0005-0.01;

[0021] (Raw material example: the raw material of Al element is α-Al 2 o 3 ; Sr, Mg, Ca, Ba, Eu, Dy, La, Nd, Tb and Ce elements are their oxides or carbonates).

[0022] 2. Dry and sieve the powder of the mixture in N 2 / H 2 (75%N 2 +25%H 2 ) calcining at 700-1100°C for 2-4 hours in a reducing atmosphere furnace;

[0023] 3. Again in N 2 / H 2 (75%N 2 +25%H 2 ) Calcined at 1250-1400℃ for 3-5 hours in a reducing atmosphere furnace to form M (1-x-y-z) Al 2 o 4 :xEu 2+ , 2xDy, yR 3+ , zCe 3++ crystal structure blocks;

[0024] 4. Crushing and grinding.

Embodiment 2

[0026] The preparation method of above-mentioned light-emitting film 4 is:

[0027] 1. Mix and knead one or more of the above-mentioned luminous materials in PP, PE, PC, PS, ABS, PVC, PET, and the above-mentioned luminescent materials together. Among them, the weight ratio of the polymer resin is 20% to 80%. Material 80%~20% (particle size 100~800 mesh);

[0028] 2. The mixed material that has been banburyed is then granulated by a special granulator;

[0029] 3. Inject the granulated mixture into a special extruder to produce a luminescent film 4 with a film thickness of 0.2-3mm.

Embodiment 3

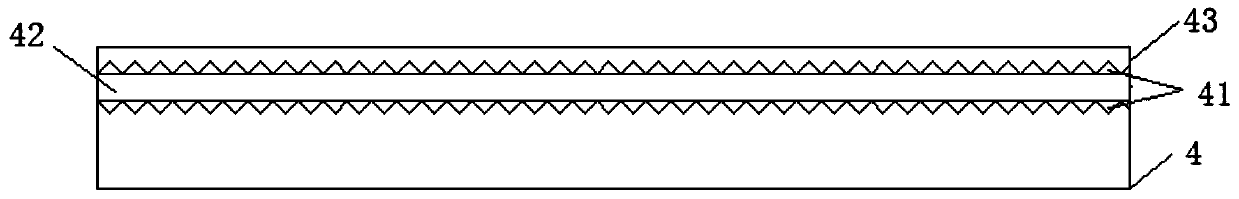

[0031] In order to better improve the homogenization of the tunnel lighting lamp in the present invention, on the basis of the preparation of the above-mentioned luminous film 4, as image 3 As shown, a grating 41 can be micro-engraved on one side of the luminescent film 4, and a 0.2-1mm thick uniform film 43 with a grating diffraction effect can be bonded outside the grating 41 through a transparent resin organic glue 42. The uniform film 44 can be made of PP, PE , PC, PS, ABS, PVC, PET, and one or more polymer transparent resins, and the grating constant d of the luminescent film 4 and the uniform light film 43 is selected to be 10nm-100um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| reflection | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com