Solar photovoltaic-thermal system and manufacturing process thereof

A thermal system and solar energy technology, applied in the direction of photovoltaic thermoelectric hybrid power generation, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of poor product reliability, high manufacturing cost, low energy utilization rate, etc., and achieve convenient production and assembly, long service life, The effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

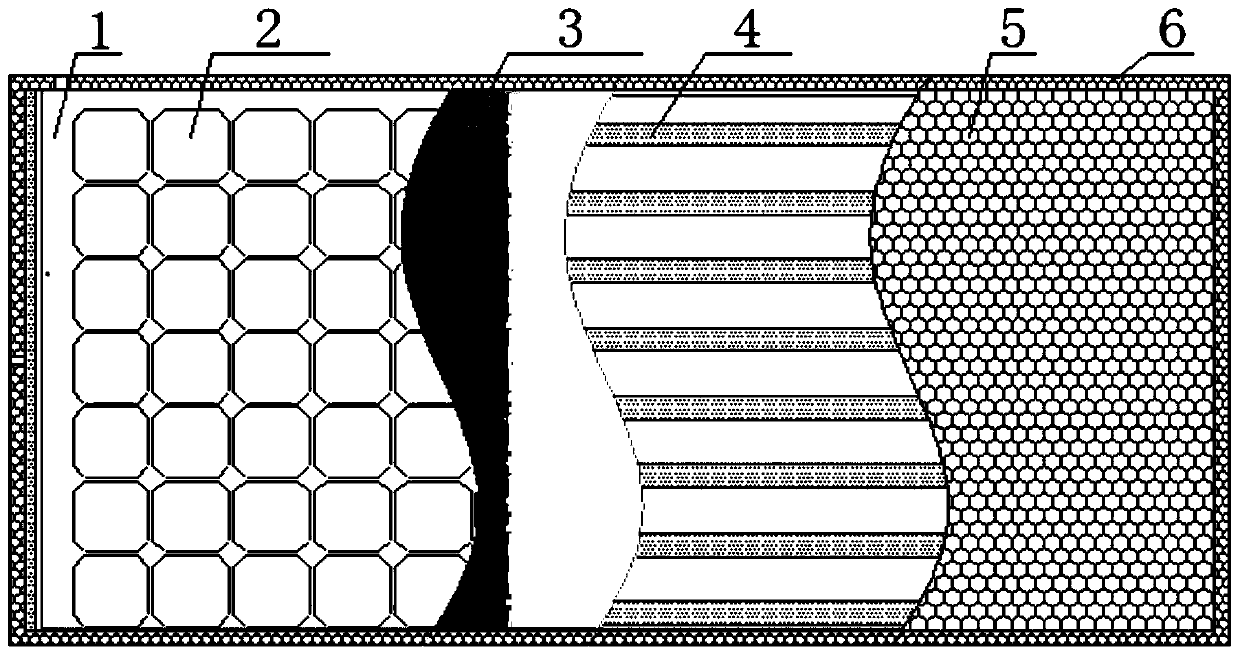

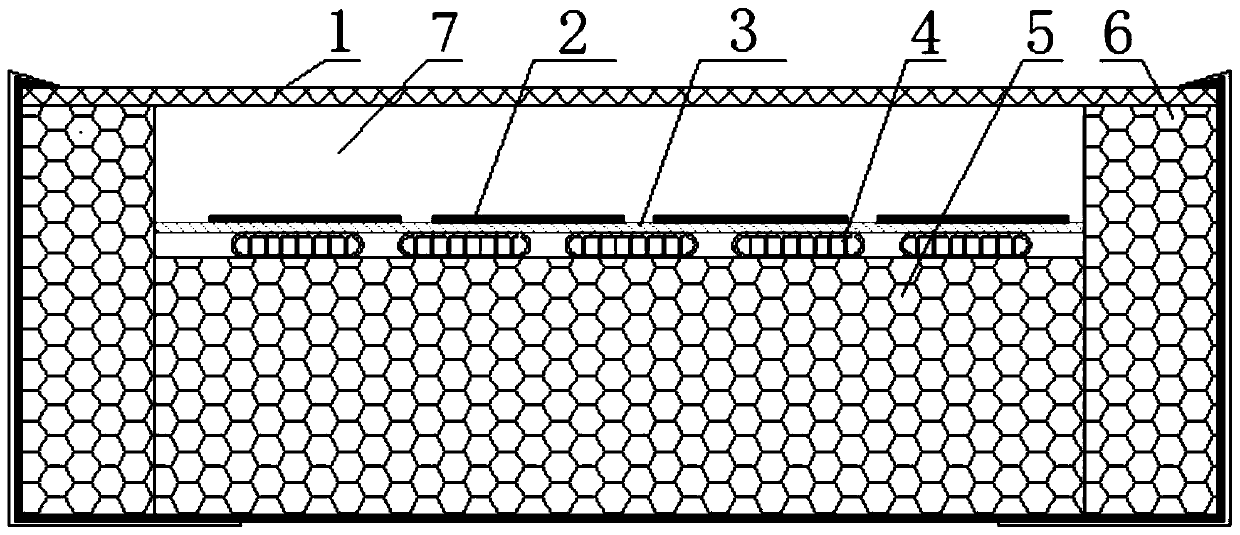

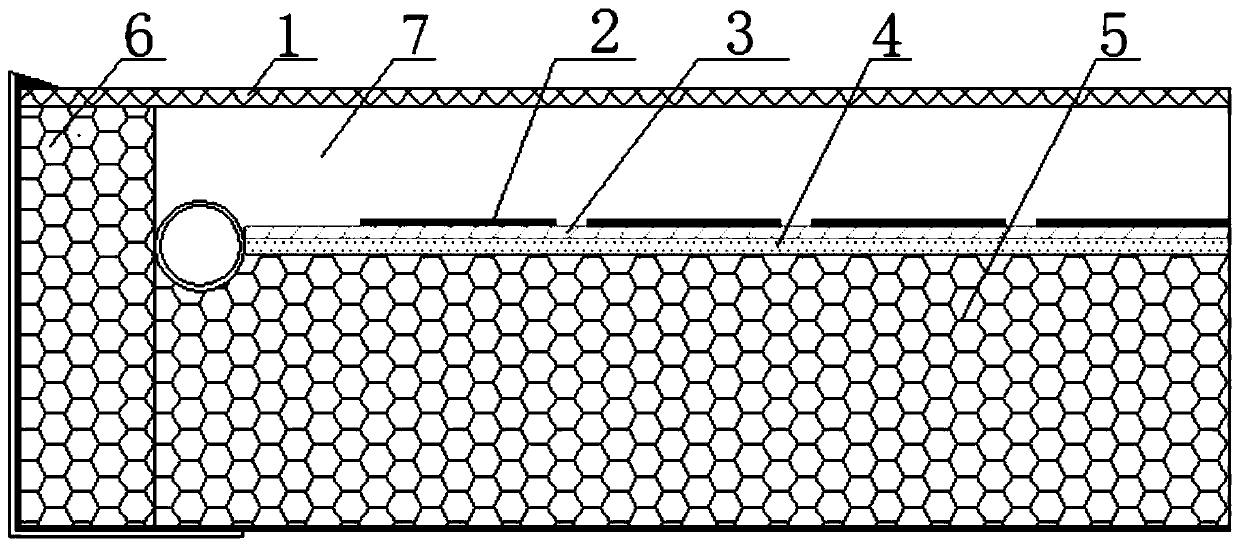

[0023] This embodiment provides a solar photovoltaic photothermal system, such as figure 1 Shown is the top view of the photovoltaic photothermal system provided by the present invention, figure 2 and image 3 The long side section and the short side section view of the system are shown, which include a metal frame body 6 with accommodating space, an insulation layer 5 arranged in the metal frame body 6, and a microchannel heat exchanger arranged on the upper surface of the insulation layer 5 4. The glass substrate 3 arranged on the upper surface of the microchannel heat exchanger 4, the photovoltaic module arranged on the upper surface of the glass substrate 3, the glass cover plate 1 installed above the corresponding photovoltaic module, and the photovoltaic module and the glass cover The heat insulation layer 7 arranged between the boards 1, in this embodiment, the heat insulation layer 7 is specifically an air layer; the core element of the photovoltaic module is a photo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com