Hydrotalcite-like composite material and preparation method thereof

A composite material, hydrotalcite technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of complex process and high cost, and achieve the effect of firm bonding, simple manufacturing process and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

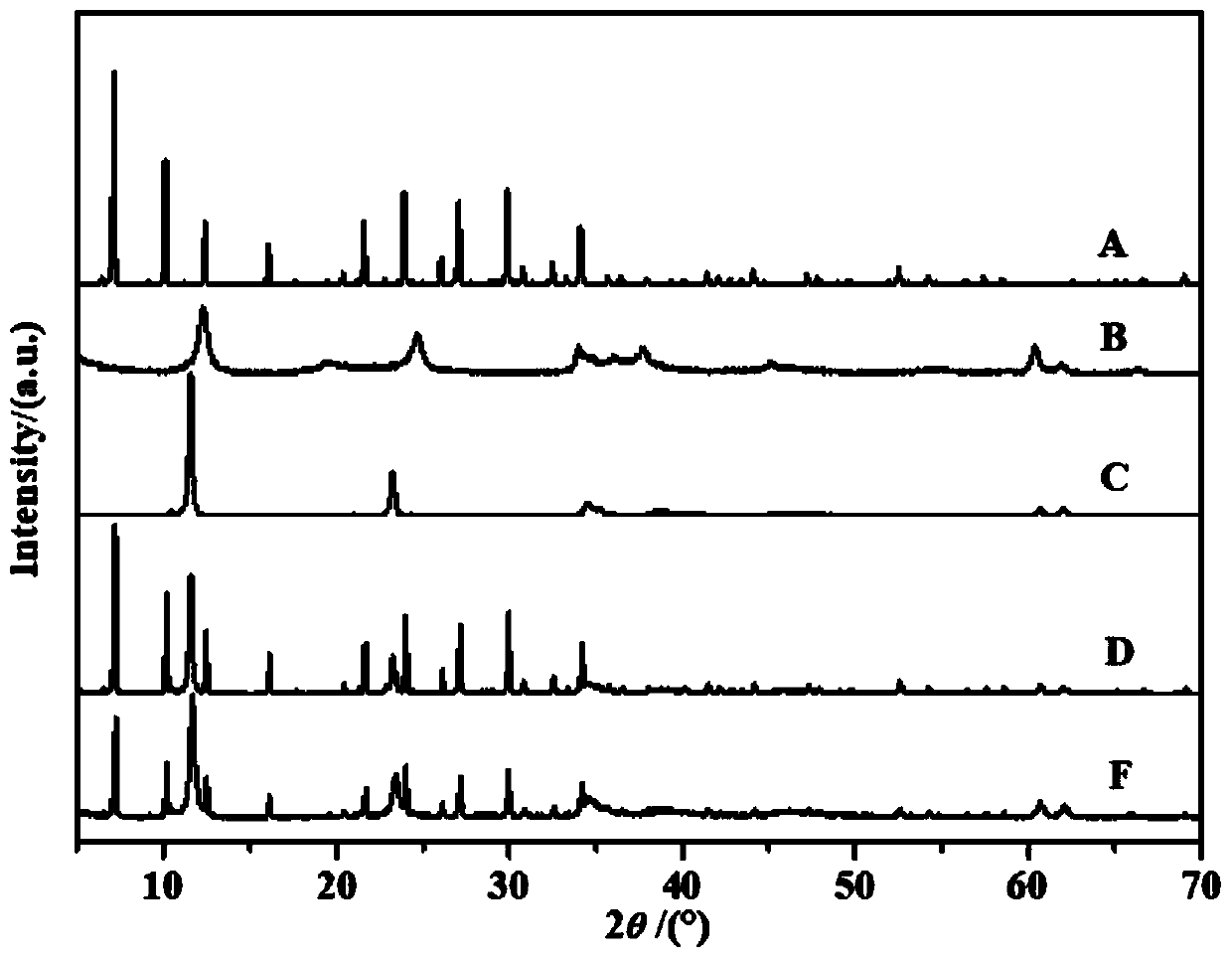

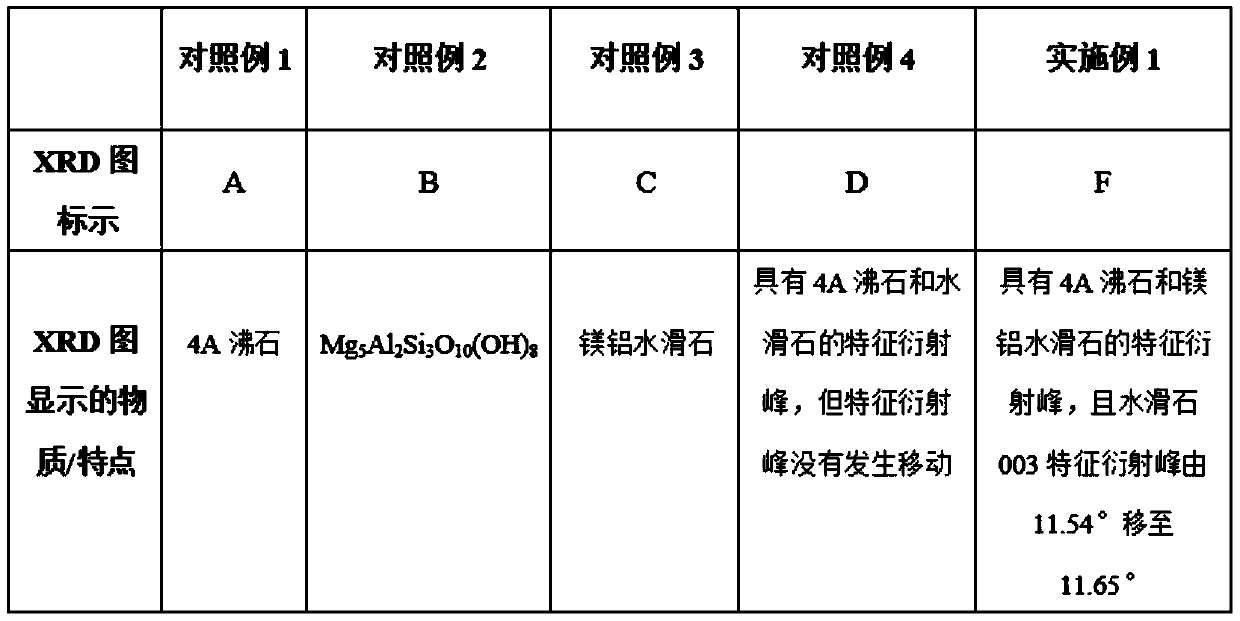

Image

Examples

preparation example Construction

[0039] The preparation method of the hydrotalcite-like composite material of the first aspect embodiment of the present invention comprises the following steps:

[0040] Step 1: Mix A-type zeolite, silane coupling agent and water, and mix and stir at a temperature of 30-80° C. to obtain a first slurry.

[0041] Wherein, the ratio of the A-type zeolite to water is: 100g A-type zeolite: 500-1500mL water, and the dosage of the silane coupling agent is 0.5%-10% of the A-type zeolite mass.

[0042] As preferably, A-type zeolite, silane coupling agent and water are mixed, and the proportioning of the three is:

[0043] Type A zeolite: water: silane coupling agent is 100g: 750mL: 5g.

[0044] Preferably, after mixing the A-type zeolite, the silane coupling agent and water, the mixed slurry is stirred at a temperature of 60°C.

[0045] Among them, mixing and stirring for 60 minutes at a temperature of 30-80° C. is more appropriate.

[0046] Type A zeolite is cheap, has a regular pore...

Embodiment 1

[0064] Step 1: Mix 200g of 4A zeolite, 10.0g of γ-(methacryloyloxy)propyltrimethoxysilane, and 1500mL of water, and stir at reflux at 60°C for 60min to obtain the first slurry;

[0065] Step 2: Add 215.02g of magnesium nitrate hexahydrate and 157.29g of aluminum nitrate nonahydrate to the first slurry, stir for 0.5h, and stir evenly to obtain the second slurry;

[0066] Step 3: Add 22.22 g of anhydrous sodium carbonate to the second slurry and stir evenly, then add sodium hydroxide, adjust the pH to 13.0 and stir evenly to obtain the third slurry;

[0067] Step 4: crystallize the obtained third slurry at 135° C. for 12 hours, then cool and filter, wash, dry and pulverize the filter cake to obtain the magnesium aluminum hydrotalcite / 4A zeolite composite material.

[0068] The magnesium aluminum hydrotalcite / 4A zeolite composite material prepared in Example 1 has good dispersion properties, and has the advantages of low cost, mild preparation conditions, and simple process.

Embodiment 2

[0070] Step 1: Mix 200g of 4A zeolite, 1g of n-octyltriethoxysilane, and 1000mL of water, and stir at reflux at 30°C for 5min to obtain the first slurry;

[0071] Step 2: Add 215.02g of magnesium nitrate hexahydrate and 157.29g of aluminum nitrate nonahydrate to the first slurry, stir for 0.2h, and stir evenly to obtain the second slurry;

[0072] Step 3: Add 22.22 g of anhydrous sodium carbonate to the second slurry and stir evenly, then add sodium hydroxide, adjust the pH to 10.0 and stir evenly to obtain the third slurry;

[0073] Step 4: crystallize the obtained third slurry at 60° C. for 24 hours, then cool and filter, wash, dry and pulverize the filter cake to obtain the magnesium aluminum hydrotalcite / 4A zeolite composite material.

[0074] The magnesium aluminum hydrotalcite / 4A zeolite composite material prepared in Example 2 has good dispersion properties, and has the advantages of low cost, mild preparation conditions, and simple process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com