A three-dimensional ordered porous network structure of vo 2 Thin film and its preparation method and application

A porous network, three-dimensional ordered technology, applied in the direction of coating, vanadium oxide, etc., can solve the problems of film cracks and peeling, and achieve the effect of improved repeatability, difficult peeling, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation process of this thin film comprises the following steps:

[0043] (1) Use quartz glass with high light transmittance as the substrate for cleaning treatment. Concretely comprise the following steps: after the quartz glass with high light transmittance is respectively ultrasonically treated in acetone and ethanol for 20 to 90 minutes, in piranha solution (H 2 SO 4 :H 2 o 2 =7:3) for 5 to 30 minutes, ultrasonically treated in deionized water for 30 to 60 minutes; cleaned high-transmittance quartz glass as a substrate for later use.

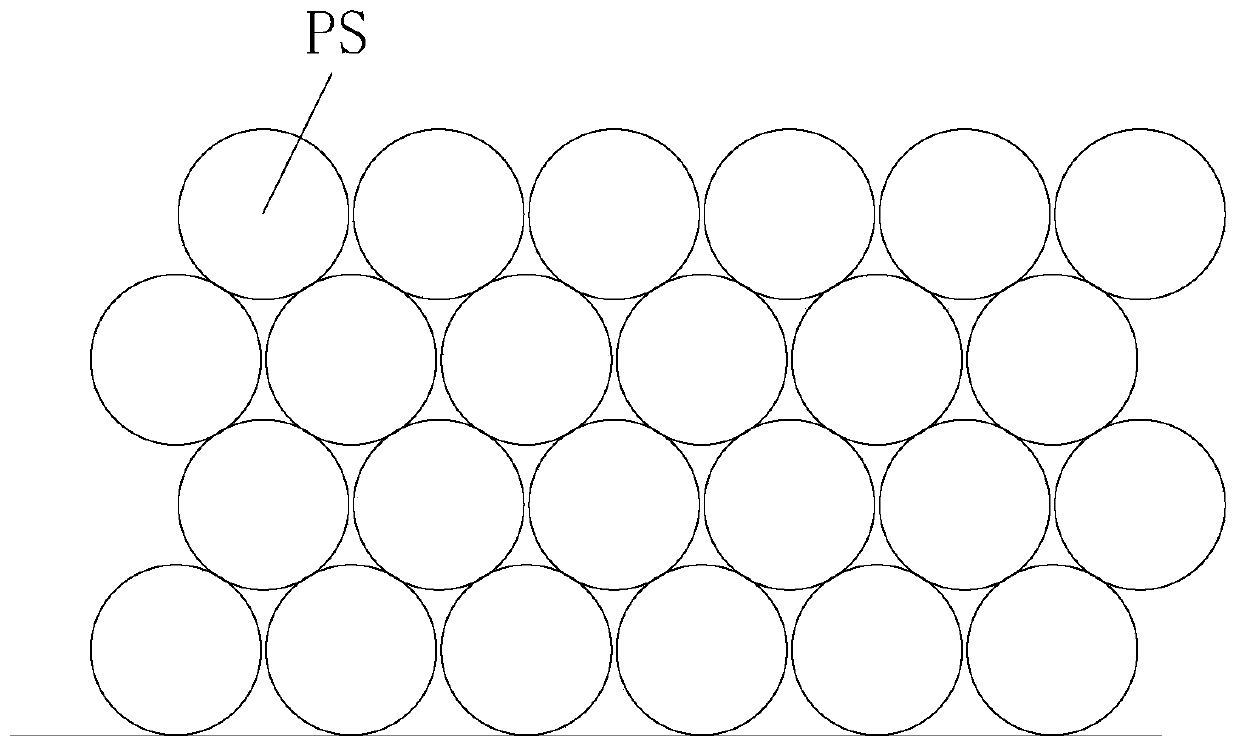

[0044] (2) Using the vertical dipping method, polystyrene (PS) microspheres are self-assembled and arranged on a glass substrate to form a VO 2 Film template. The specific process of this step is, commercially purchased or homemade PS ball emulsion, the size of PS balls in the general PS ball emulsion is 200-1500nm, the size of PS balls directly affects the size of the holes in the three-dimensional network structure; dil...

Embodiment 1

[0049] (1) The quartz sheet was ultrasonically treated in acetone and ethanol for 30 minutes respectively, soaked in piranha solution for 30 minutes, and then ultrasonically treated in deionized water for 30 minutes for later use;

[0050] (2) Add 2mL of PS sphere emulsion into 50mL of deionized water and ultrasonically disperse for 2 hours to prepare the PS sphere dilution, hang the quartz glass cleaned in step (1) vertically and dip it in the PS sphere dilution, and place it in the air to dry box, and evaporated at 60°C for 10 hours to form a PS sphere template.

[0051] (3) in 60mLCH 3 OH solution, add vanadium source, 4mL HCl and 0.25mLN 2 h 4 , to prepare V 2 o 5 Concentration is the precursor solution of 22.6mmol / L; Wherein CH 3 The volume ratio of OH and HCl is 15:1, CH 3 OH and N 2 h 4 The volume ratio is 60:0.25.

[0052] (4) Soak the self-assembled PS sphere template in VO at room temperature 2 In the blue precursor solution for 3h, remove it. Place in a b...

Embodiment 2

[0055] (1) The quartz sheet was ultrasonically treated in acetone and ethanol for 30 minutes respectively, soaked in piranha solution for 30 minutes, and then ultrasonically treated in deionized water for 30 minutes for later use;

[0056](2) Add 2 mL of PS sphere emulsion into 50 mL of deionized water and ultrasonically disperse for 2 hours to prepare a PS sphere dilution. Hang and immerse the cleaned quartz glass in step (1) in the PS sphere dilution, and place it in a blast drying oven. Evaporated at 60°C for 12 hours to form a PS sphere template.

[0057] (3) in 60mLCH 3 OH solution, sequentially add vanadium source, 8mL HCl and 0.5mLN 2 h 4 , to prepare V 2 o 5 Concentration is the precursor solution of 33.9mmol / L; Wherein CH 3 The volume ratio of OH and HCl is 15:2, CH 3 OH and N 2 h 4 The volume ratio is 60:0.5.

[0058] (4) Soak the self-assembled PS sphere template in VO at room temperature 2 In the blue precursor solution for 5h, remove it. Place in a blas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com