Porphyrin sensitization carbon nitride photocatalyst for producing hydrogen peroxide and preparation method of photocatalyst

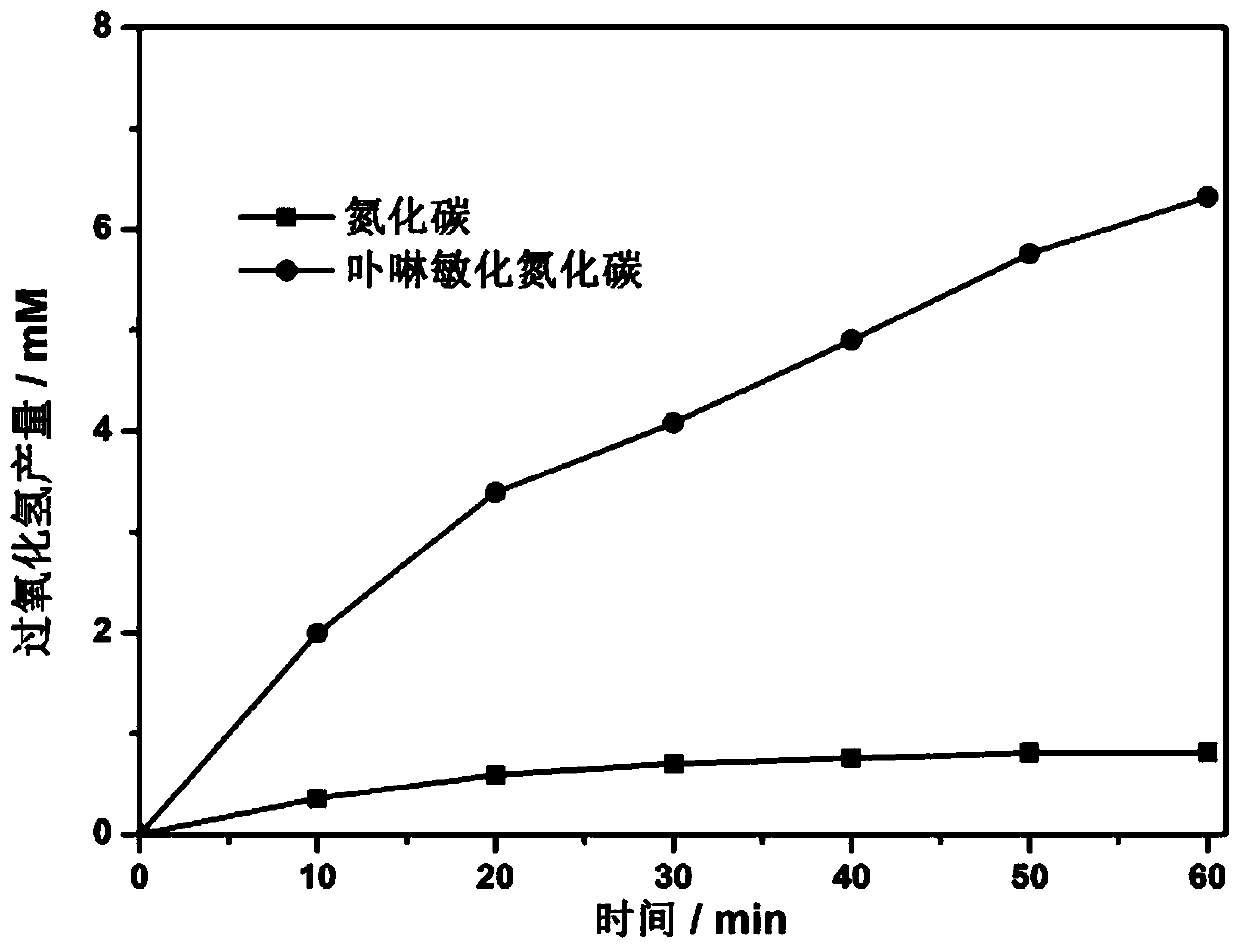

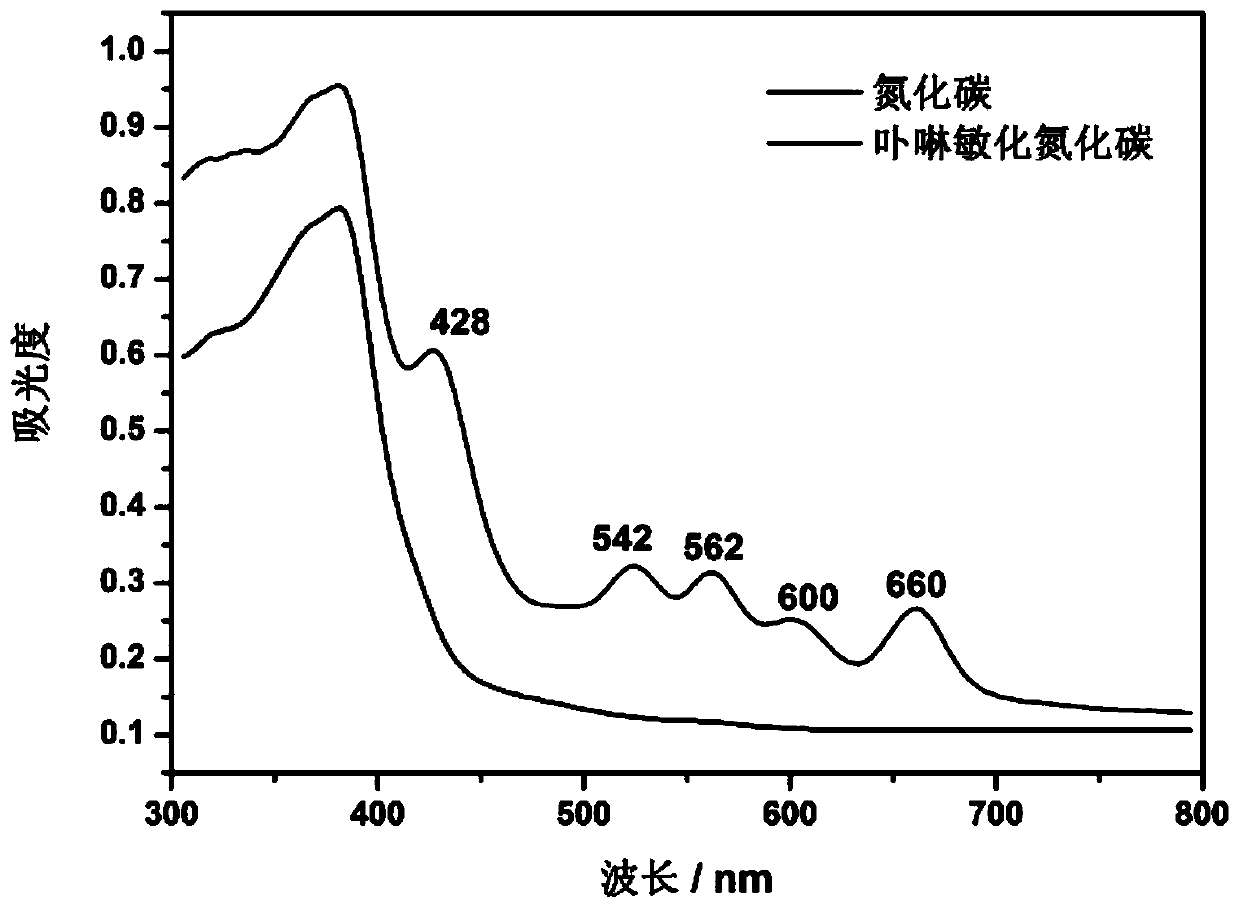

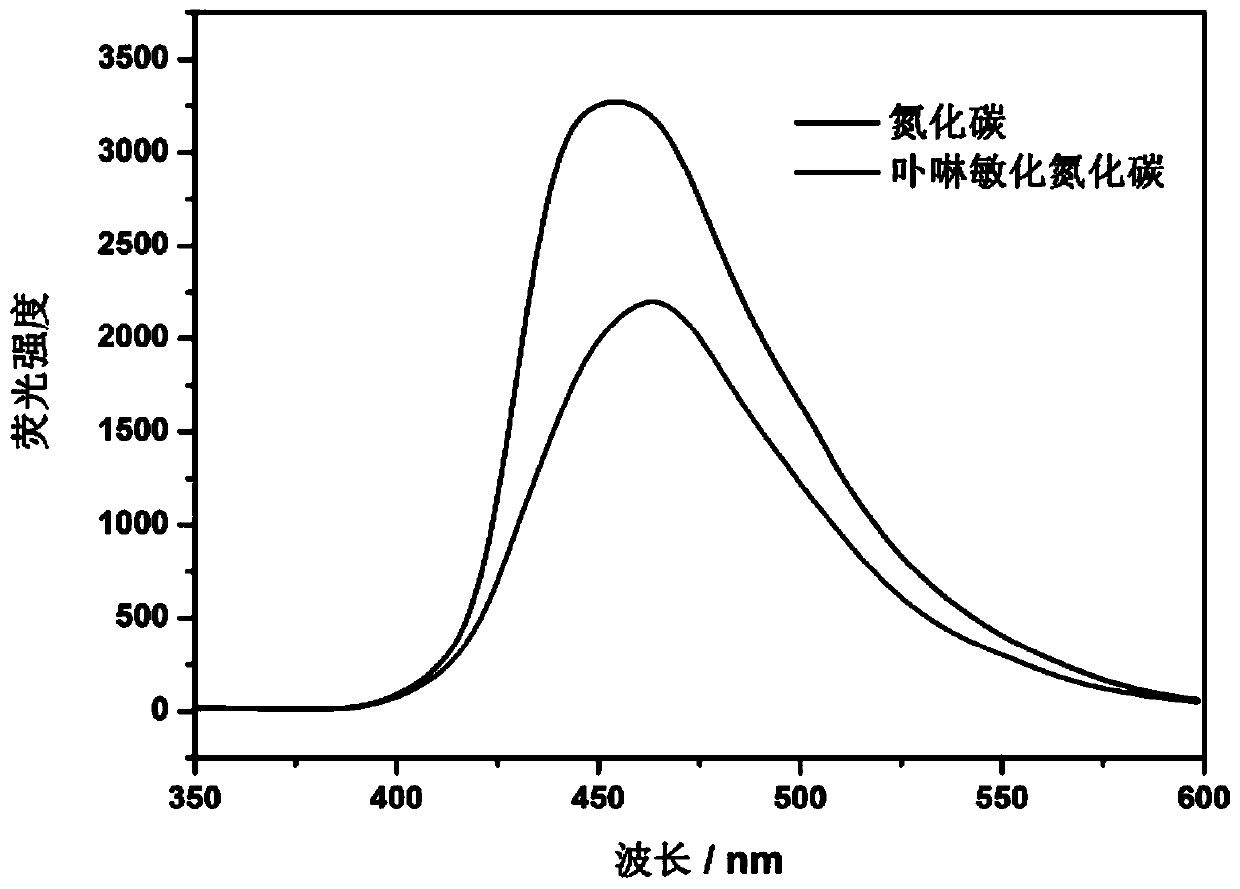

A technology for porphyrin sensitization of carbon nitride and hydrogen peroxide, applied to organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, peroxides/peroxyhydrates/peroxyacids/super Oxides/ozonides and other directions can solve the problems of high photogenerated electron-hole pair recombination rate, low hydrogen peroxide production efficiency, and low quantum efficiency, and achieve low raw material cost, excellent visible light effect, and the effect of inhibiting recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing a porphyrin-sensitized carbon nitride composite photocatalyst for producing hydrogen peroxide, comprising the steps of:

[0036] (1) Take 5 g of melamine and place it in a muffle furnace, heat it up to 550 °C for 4 hours at a heating rate of 1 °C / min and calcinate it for 4 hours, grind the resulting solid into a fine powder with a particle size of 50 μm, and then heat it at a heating rate of 5 °C / min The heating rate is raised to 500°C for 2 hours and calcined to obtain carbon nitride nanosheets;

[0037] (2) Dissolve 5.58g of p-bromobenzaldehyde and 2.1mL of pyrrole in 150mL of nitrobenzene, add 225mL of acetic acid, mix well, and react at 120°C for 1 hour. After the reaction, filter the filter residue and use methanol and deionized Washed with water, then recrystallized with methanol and chloroform to obtain the product porphyrin;

[0038] (3) Dissolving the porphyrin obtained in step (2) in tetrahydrofuran to obtain a porphyrin solution, the c...

Embodiment 2

[0046] A method for preparing a porphyrin-sensitized carbon nitride composite photocatalyst for producing hydrogen peroxide, comprising the steps of:

[0047] (1) Take 5g of melamine and place it in a muffle furnace, heat up to 500°C for 3 hours at a heating rate of 0.5°C / min and calcinate for 3 hours. The heating rate was increased to 450°C for 2.5 hours and calcined to obtain carbon nitride nanosheets;

[0048] (2) Dissolve 3g of p-bromobenzaldehyde and 1.13mL of pyrrole in 150mL of nitrobenzene, add 150mL of acetic acid, mix well, and react at 130°C for 2 hours. After the reaction, filter the filter residue and wash it with methanol and deionized water Washing, then recrystallization with methanol and chloroform to obtain the product porphyrin;

[0049] (3) dissolving the porphyrin obtained in step (2) in tetrahydrofuran to obtain a porphyrin solution, the concentration of the porphyrin solution is 0.1 mg / mL;

[0050] (4) Take 0.15g of carbon nitride nanosheets and ultras...

Embodiment 3

[0053] A method for preparing a porphyrin-sensitized carbon nitride composite photocatalyst for producing hydrogen peroxide, comprising the steps of:

[0054] (1) Take 5g of melamine and place it in a muffle furnace, heat up to 600°C for 5 hours at a heating rate of 2°C / min and calcinate for 5 hours, grind the resulting solid into a fine powder with a particle size of 100 μm, and then heat it at a heating rate of 10°C / min The heating rate is raised to 400°C for 3 hours and calcined to obtain carbon nitride nanosheets;

[0055] (2) Dissolve 9g of p-bromobenzaldehyde and 3.37mL of pyrrole in 150mL of nitrobenzene, add 300mL of acetic acid, mix well, and react at 140°C for 3 hours. After the reaction, filter the filter residue and wash it with methanol and deionized water Washing, then recrystallization with methanol and chloroform to obtain the product porphyrin;

[0056] (3) The porphyrin obtained in step (2) is dissolved in tetrahydrofuran to obtain a porphyrin solution, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com