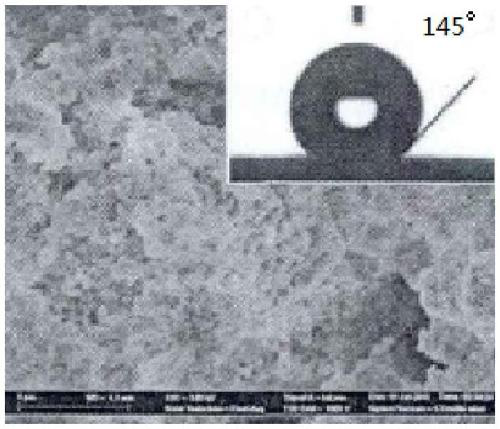

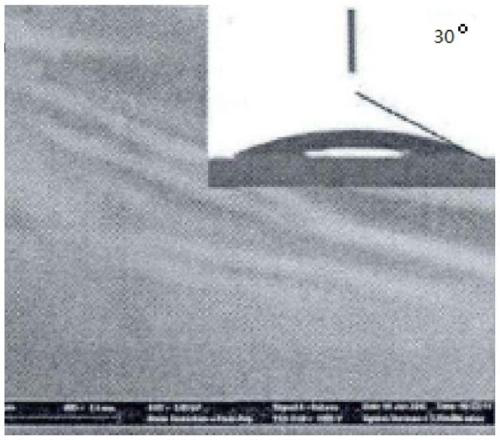

Self-cleaning coating applied to doors and windows, and preparation method thereof

A self-cleaning coating and self-cleaning technology, used in coatings, anti-corrosion coatings, paints containing biocides, etc. Increases adhesion, good cohesion and peelability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

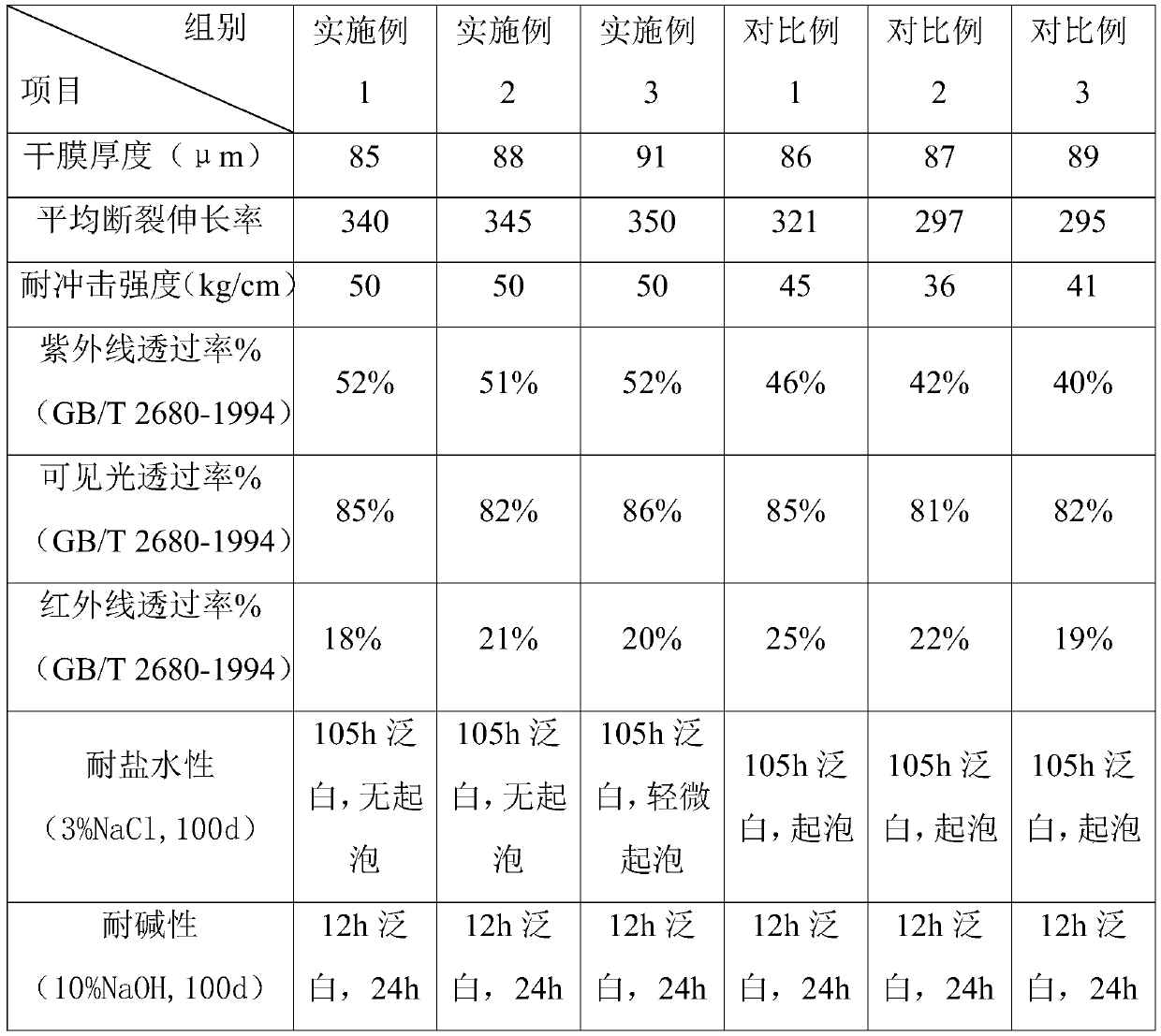

Embodiment 1

[0027] In this embodiment, a self-cleaning coating applied to doors and windows is provided, including the following components by mass percentage: 40 parts of modified polyurethane monomer dispersion, 5 parts of nano-titanium dioxide, 1.6 parts of nano-zinc oxide, and 25 parts of coupling agent , 0.1 part of leveling agent, 10 parts of solvent, 0.1 part of film-forming agent, 1.2 parts of co-emulsifier, 9 parts of emulsifier, 0.08 part of initiator; and the modified polyurethane monomer dispersion is composed of polyether glycol, The carboxyl-containing half-ester diol and butyl acrylate are added to the disperser according to the weight ratio of 5:2:1, and stirred at a speed of 1500r / min for 20min to react.

[0028] Wherein, the particle size of the nano-titanium dioxide is 10nm; the coupling agent is selected from silane coupling agent; the leveling agent is selected from butyl cellulose; the solvent is dehydrated alcohol; The film agent is glycol ether; the emulsifier is s...

Embodiment 2

[0035] In this embodiment, a self-cleaning coating applied to doors and windows is provided, including the following components in mass percentage: 60 parts of modified polyurethane monomer dispersion, 25 parts of nano-titanium dioxide, 1.6 parts of nano-zinc oxide, and 25 parts of coupling agent , 0.1 part of leveling agent, 10 parts of solvent, 0.8 part of film forming agent, 1.2 parts of co-emulsifier, 9 parts of emulsifier, 0.08 part of initiator; and the modified polyurethane monomer dispersion is composed of polyether glycol, The carboxyl-containing half-ester diol and butyl acrylate are added to the disperser according to the weight ratio of 7:2:1, and stirred at a speed of 1500r / min for 20-45min to react.

[0036] Wherein, the particle size of the nano titanium dioxide is 35nm; the coupling agent is selected from silane coupling agent; the leveling agent is selected from GLP-588 leveling agent; the solvent is ethylene glycol; The film forming agent is vinyl glycol buty...

Embodiment 3

[0043] In this embodiment, a self-cleaning coating applied to doors and windows is provided, including the following components in mass percentage: 50 parts of modified polyurethane monomer dispersion, 20 parts of nano-titanium dioxide, 0.08 parts of nano-zinc oxide, and 18 parts of coupling agent , 0.4 parts of leveling agent, 12 parts of solvent, 0.7 part of film-forming agent, 0.5 part of co-emulsifier, 5 parts of emulsifier, 0.04 part of initiator; and the modified polyurethane monomer dispersion is composed of polyether glycol, The carboxyl-containing half-ester diol and butyl acrylate are added to the disperser according to the weight ratio of 6:1:1, and the reaction is obtained by stirring at a speed of 1200r / min for 30min.

[0044] Wherein, the particle diameter of described nano-titanium dioxide is 20nm; Described coupling agent is selected from silane coupling agent; Described leveling agent is selected from the mixing of butyl cellulose and hydroxymethyl cellulose; D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com