Nanometer zirconium dioxide with high specific surface area and preparation method thereof

A technology of nano zirconia and high specific surface area, which is applied in nanotechnology, zirconia, nanotechnology, etc. for materials and surface science, and can solve the unpublished primary particle size of zirconia, which is unfavorable for industrial production and preparation process cumbersome and other problems, to achieve the effect of eliminating post-processing, low cost, and simple post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 1383.5g of zirconium oxychloride, add water to dilute to a concentration of 0.4mol / l, take 10.15L of the solution, add PEG20000-10g, the molar ratio of zirconium oxychloride to ammonia water is 1:3.5, take 1.1L of ammonia water, and dilute to 14.2L, positive sedimentation, dropping time 2h, after precipitation, add 2% sodium dodecylbenzenesulfonate, stir for 1h, age at room temperature for 2h, suction filter, wash with water, water temperature 60℃, wash until pH is about 7 , and then washed with 10L ethanol, baked at 90°C for 15 hours, burned at 500°C, kept for 2 hours, and sieved to obtain nano-zirconia.

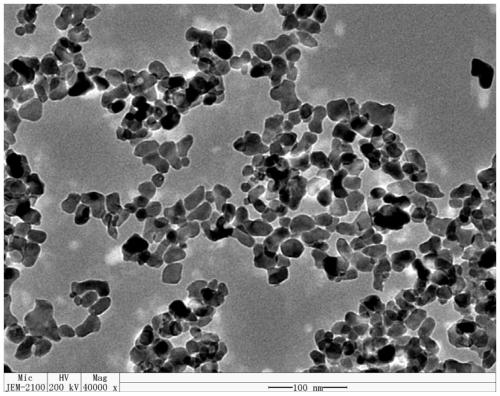

[0031] After TEM detection, the primary particle size is: 10-30nm, the particles are uniformly dispersed, and the BET is 68m 2 / g.

[0032] figure 1 For the TEM figure of the nano zirconium dioxide that this embodiment makes, from figure 1 It can be seen that the particles are well dispersed and relatively uniform in size, with a size of 10-30nm.

Embodiment 2

[0034] Weigh 2767g of zirconium oxychloride, add water to dilute to a concentration of 0.5mol / l, take 16.23L of the solution, add 30g of n-butanol, the molar ratio of zirconium oxychloride to sodium hydroxide is 1:3.0, and take 974g of sodium hydroxide , dilute to 48.7L, positively settle, add dropwise for 5 hours, add 3% sodium dodecylbenzenesulfonate after precipitation, stir for 1 hour, age at room temperature for 3 hours, filter with suction, wash with water, water temperature 70°C, wash to pH 7, then wash with 25L of ethanol, bake at 90°C for 18 hours, burn at 550°C, keep warm for 2 hours, and sieve to obtain nano-zirconia.

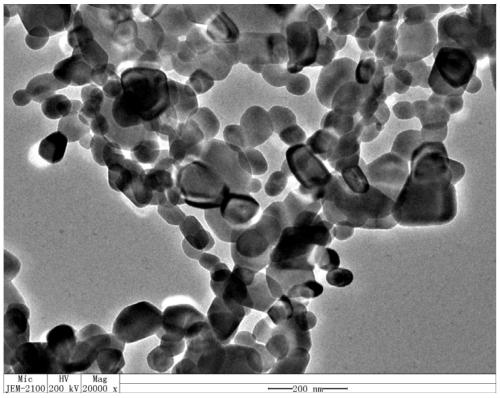

[0035] After TEM detection, the primary particle size is: 10-30nm, the particles are uniformly dispersed, and the BET is 80m 2 / g.

Embodiment 3

[0037] Weigh 5534g of zirconium oxychloride and prepare it to a concentration of 0.8mol / l. Take 20.3L of this solution, add 80g of n-butanol, the molar ratio of zirconium oxychloride to ammonia water is 1:4, take 5L of ammonia water, and dilute to 43.17L , is settling, and the dropping time is 5 hours. After the precipitation, add 5% sodium lauryl sulfate, stir for 1 hour, age at room temperature for 3 hours, filter with suction, wash with water, and wash at a water temperature of 80°C until the pH is about 7, and then use Wash with 30L ethanol, bake at 90°C for 20 hours, burn at 600°C, keep warm for 3 hours, and sieve to obtain nano-zirconia.

[0038] After TEM detection, the primary particle size is: 10-30nm, the particles are uniformly dispersed, and the BET is 75m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com