Plastic with graphene/anthraquinone compound composite grafted on surface and preparing method and application of plastic

A technology of surface grafting and composite materials, which is applied in the field of plastics for the preparation of surface grafted graphene/anthraquinone compound composite materials, can solve the problems of weak binding force, unfavorable environment and operators, etc., and achieve low cost and high growth rate. Fast biodegradation rate, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

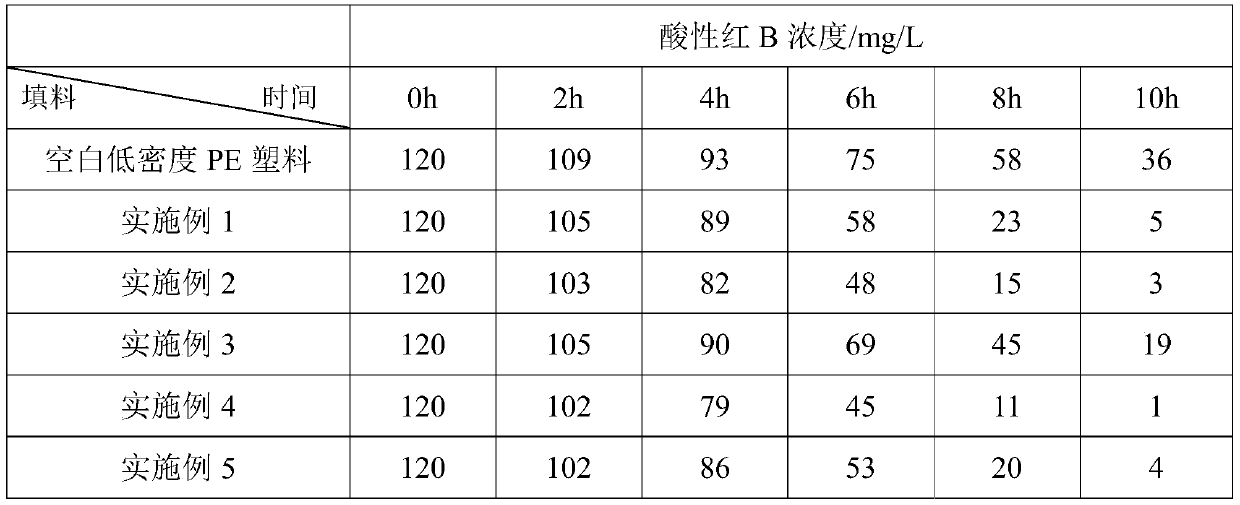

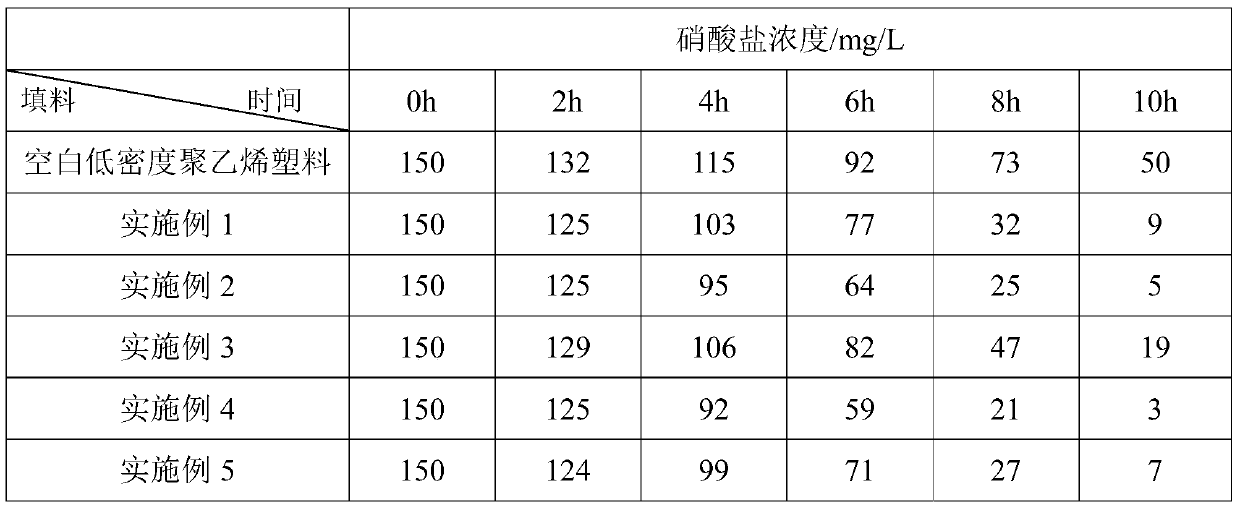

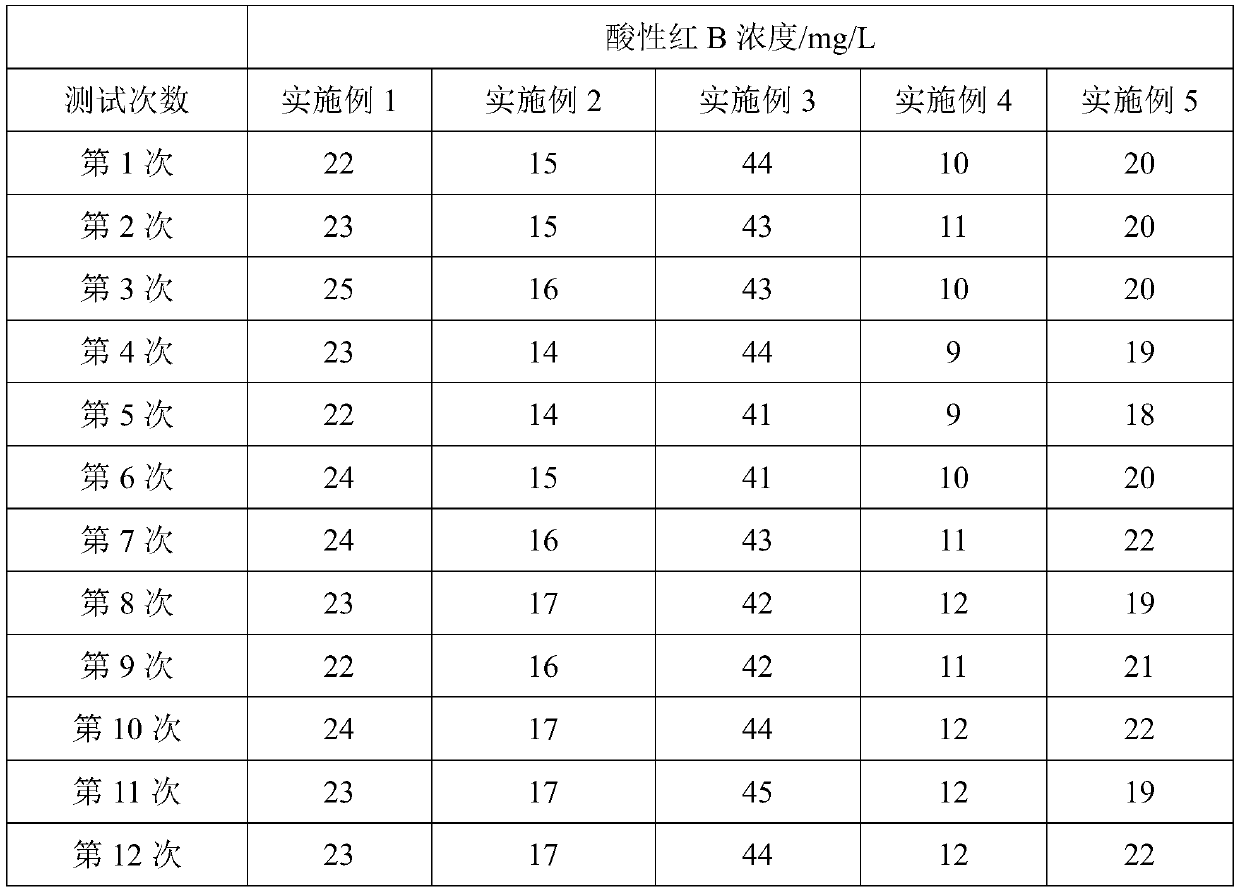

Examples

Embodiment 1

[0039] Hydrophilic modification of the surface of low-density PE plastic with an average particle size of 0.2mm by ozone;

[0040] Add 6 parts of 3-aminopropyltrimethoxysilane to 100 parts of alcohol aqueous solution with a volume ratio of 95:5, stir for half an hour, add 40 parts of the above-mentioned low-density PE plastic with hydrophilic surface, raise the temperature to 55°C, and react for 1.5 hour, filter, filter out the solid and wash three times with absolute ethanol, dry to obtain amino-modified low-density PE plastics;

[0041] Add 1 part of modified Hummers method graphene oxide to 500 parts of tetrahydrofuran, ultrasonically disperse, add 10 parts of the above-mentioned amino-modified low-density PE plastic, stir and react for 1 hour, filter, filter out the solid, wash it with absolute ethanol three times, and dry , to obtain low-density PE plastics with graphene oxide grafted on the surface;

[0042] Ultrasonically disperse 100 parts of the above-mentioned low-d...

Embodiment 2

[0046] Use plasma to modify the surface of PP plastic with an average particle size of 0.05mm;

[0047] Add 9 parts of 3-aminopropyltriethoxysilane to 100 parts of alcohol aqueous solution with a volume ratio of 95:5, stir for half an hour, add 45 parts of the above-mentioned PP plastic with hydrophilic surface, raise the temperature to 60°C, and react for 2 hours , filtered, the filtered solid was washed three times with absolute ethanol, and dried to obtain amino-modified PP plastics;

[0048] Add 1 part of modified Hummers method graphene oxide to 600 parts of tetrahydrofuran, ultrasonically disperse, add 15 parts of the above-mentioned amino-modified PP plastic, stir and react for 1 hour, filter, filter out the solid and wash it with absolute ethanol three times, and dry to obtain Graphene oxide modified PP plastic;

[0049] Ultrasonic disperse 100 parts of the above-mentioned graphene oxide modified PP plastic in 750 parts of tetrahydrofuran, add 15 parts of carbodiimide...

Embodiment 3

[0052] Hydrophilic modification of the surface of semi-soft fillers for sewage treatment by electron beams;

[0053] Add 5 parts of 3-aminopropylmethyldiethoxysilane to 100 parts of alcohol aqueous solution with a volume ratio of 95:5, stir for half an hour, add 35 parts of semi-soft filler with hydrophilic surface, and heat up to 65°C. React for 2 hours, filter, filter out the solid, wash it three times with absolute ethanol, and dry to obtain the amino-modified semi-soft filler;

[0054] Add 1 part of modified Hummers method graphene oxide to 500 parts of tetrahydrofuran, ultrasonically disperse, add 20 parts of the above-mentioned amino-modified semi-soft filler, stir and react for 1.5 hours, filter, filter out the solid and wash it with absolute ethanol three times, Dry to obtain graphene oxide modified semi-soft filler;

[0055] Ultrasonically disperse 100 parts of the above-mentioned graphene oxide modified semi-soft filler in 500 parts of tetrahydrofuran, add 20 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com