Manufacturing method of flame-resistant wood floor in architectural decoration and finishing

A manufacturing method and technology of wooden flooring, applied in the direction of building structure, construction, manufacturing tools, etc., can solve the problems of life, property and living environment hazards, non-reusable, high installation costs, etc., and achieve the elimination of fire safety hazards and flame retardant performance Highly consistent, the effect of reducing environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

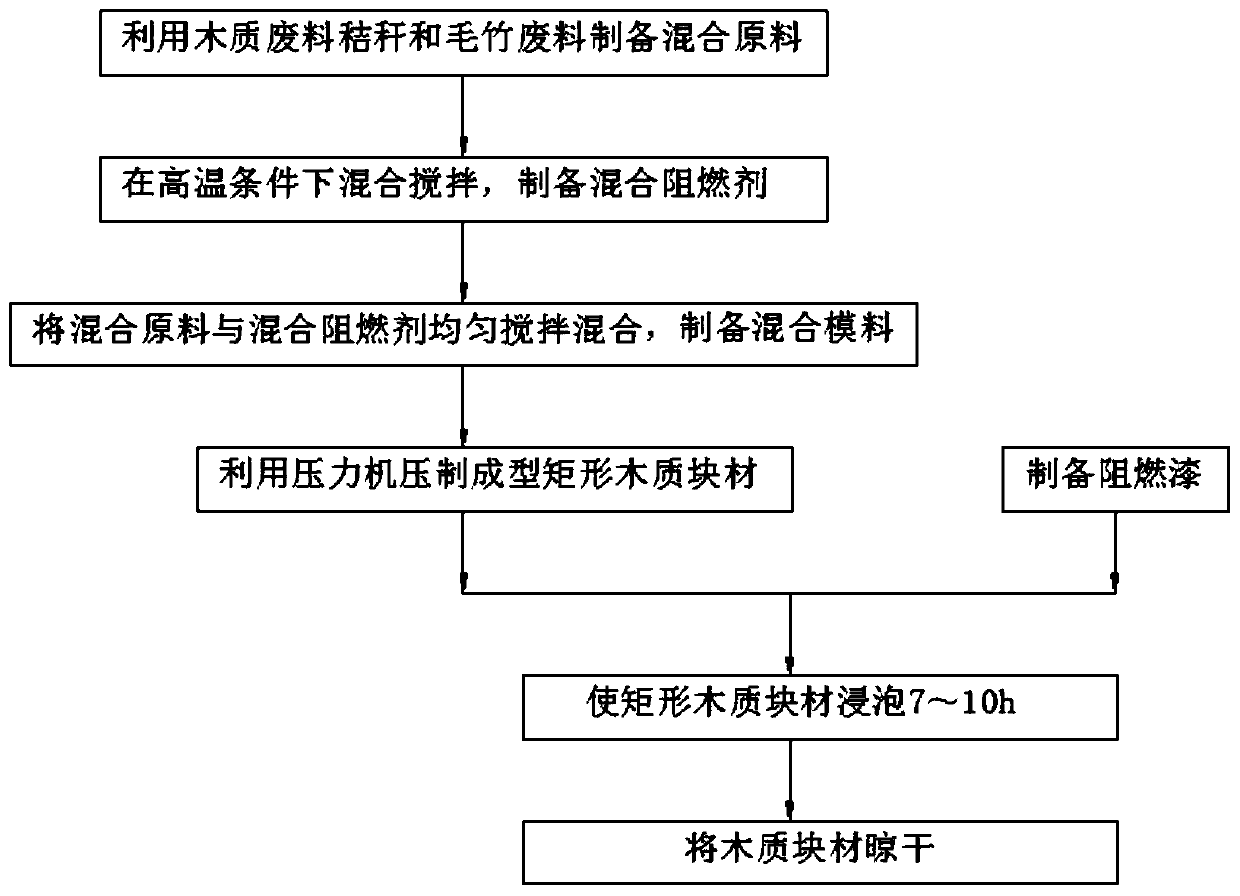

[0038] A kind of fire-retardant wooden floor manufacturing method used in building decoration engineering comprises the following steps:

[0039] Step 1: Preparation of mixed raw materials: use a crusher to crush woody waste straw and moso bamboo waste, so that the particle size of the crushed woody waste straw is less than 1 cm, and the particle size of the crushed moso bamboo waste is less than 3 cm. The woody waste straw and the crushed moso bamboo waste are evenly mixed according to the mass ratio of 7:3 to prepare the mixed raw material;

[0040] Step 2: Preparation of mixed flame retardant: Mix latex powder, polyvinyl alcohol, oxalic acid, phosphoric acid, silicon dioxide, hydrophobic powder and water at 80°C according to the following parts by mass, and then cool to room temperature to prepare Obtain a mixed flame retardant; further, in the step of preparing the mixed flame retardant described in step 2, the latex powder, polyvinyl alcohol, oxalic acid, phosphoric acid,...

Embodiment 2

[0059] A kind of fire-retardant wooden floor manufacturing method used in building decoration engineering comprises the following steps:

[0060] Step 1: Preparation of mixed raw materials: use a crusher to crush woody waste straw and moso bamboo waste, so that the particle size of the crushed woody waste straw is less than 1 cm, and the particle size of the crushed moso bamboo waste is less than 3 cm. The woody waste straw and the crushed moso bamboo waste are evenly mixed according to the mass ratio of 7:3 to prepare the mixed raw material;

[0061] Step 2: Preparation of mixed flame retardant: Mix latex powder, polyvinyl alcohol, oxalic acid, phosphoric acid, silicon dioxide, hydrophobic powder and water at 100°C according to the following parts by mass, and then cool to room temperature to prepare Obtain a mixed flame retardant; further, in the step of preparing the mixed flame retardant described in step 2, the latex powder, polyvinyl alcohol, oxalic acid, phosphoric acid...

Embodiment 3

[0080] A kind of fire-retardant wooden floor manufacturing method used in building decoration engineering comprises the following steps:

[0081] Step 1: Preparation of mixed raw materials: use a crusher to crush woody waste straw and moso bamboo waste, so that the particle size of the crushed woody waste straw is less than 1 cm, and the particle size of the crushed moso bamboo waste is less than 3 cm. The woody waste straw and the crushed moso bamboo waste are evenly mixed according to the mass ratio of 7:3 to prepare the mixed raw material;

[0082] Step 2: Preparation of mixed flame retardant: mix latex powder, polyvinyl alcohol, oxalic acid, phosphoric acid, silicon dioxide, hydrophobic powder and water according to the following mass parts at 120°C, and then cool to room temperature to prepare Obtain a mixed flame retardant; further, in the step of preparing the mixed flame retardant described in step 2, the latex powder, polyvinyl alcohol, oxalic acid, phosphoric acid, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com