Coating paint mist treatment method

A treatment method and paint coating technology, applied in gas treatment, separation methods, biological treatment devices, etc., can solve the problems of high system maintenance requirements, frequent replacement, easy failure, etc., to achieve simple equipment maintenance, reduce the number of water changes, The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

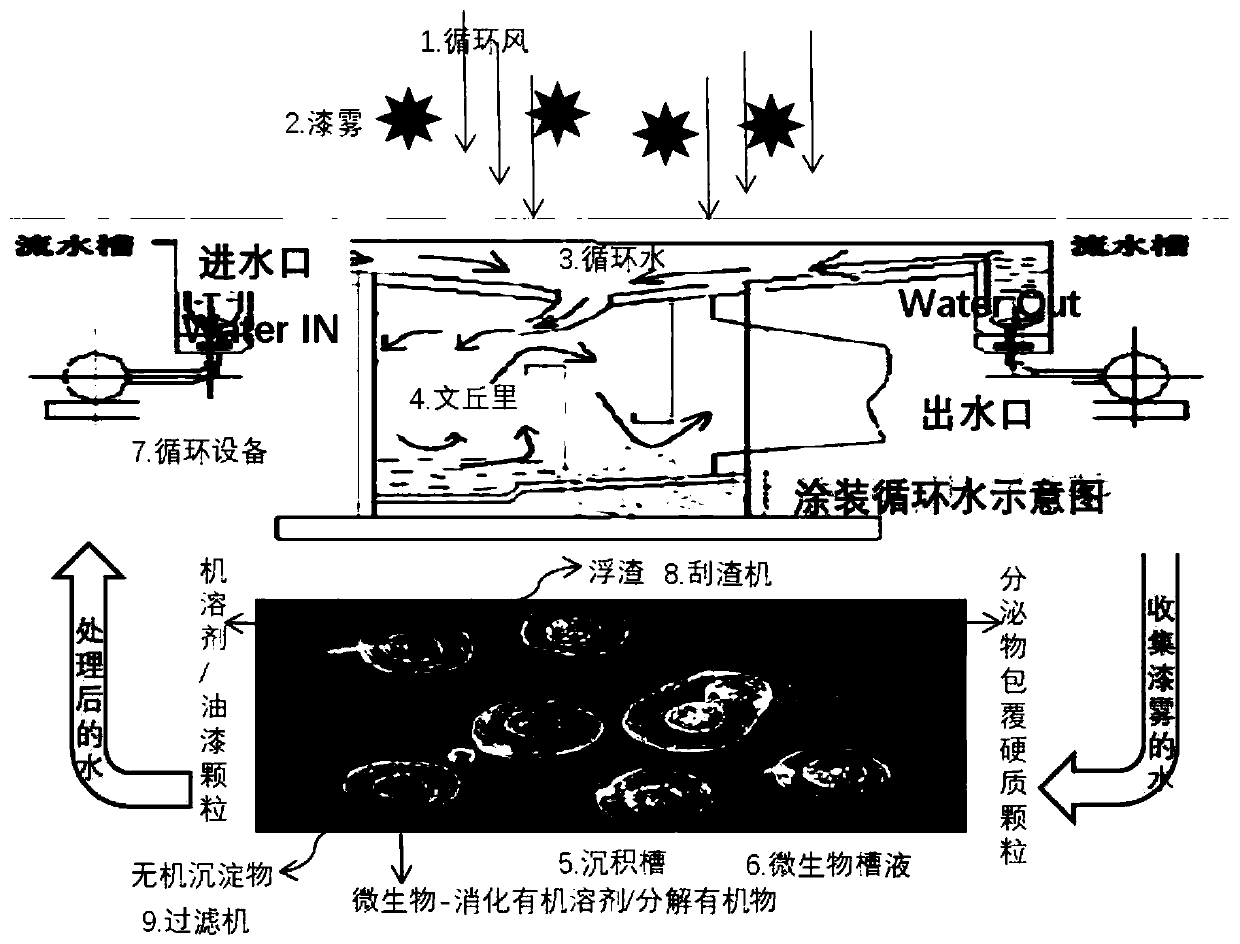

[0032] Such as figure 1 As shown, a schematic flow chart of a coating mist treatment method provided by an embodiment of the present invention is shown. The processing method includes:

[0033] (1) Coating paint mist 2 is carried by circulating air 1 into circulating water 3, washed by circulating water 3, and paint mist 2 enters the circulating water treatment system;

[0034] (2) The intercepted paint mist 2 enters the circulating water system, and the paint mist 2 is metabolized and decomposed by the microorganisms in the microbial tank 6, and a part of the remaining inorganic matter is wrapped by microbial secretions and floats on the surface of the tank liquid to be discharged. The machine 8 removes, and a part of the remaining inorganic matter is deposited at the bottom of the sedimentation tank 5 and is removed by the filter 9;

[0035] (3) The circulating water 3 in the circulating water treatment system washes the paint mist 2 and flows through the Venturi 4 and the sedime...

Embodiment 2

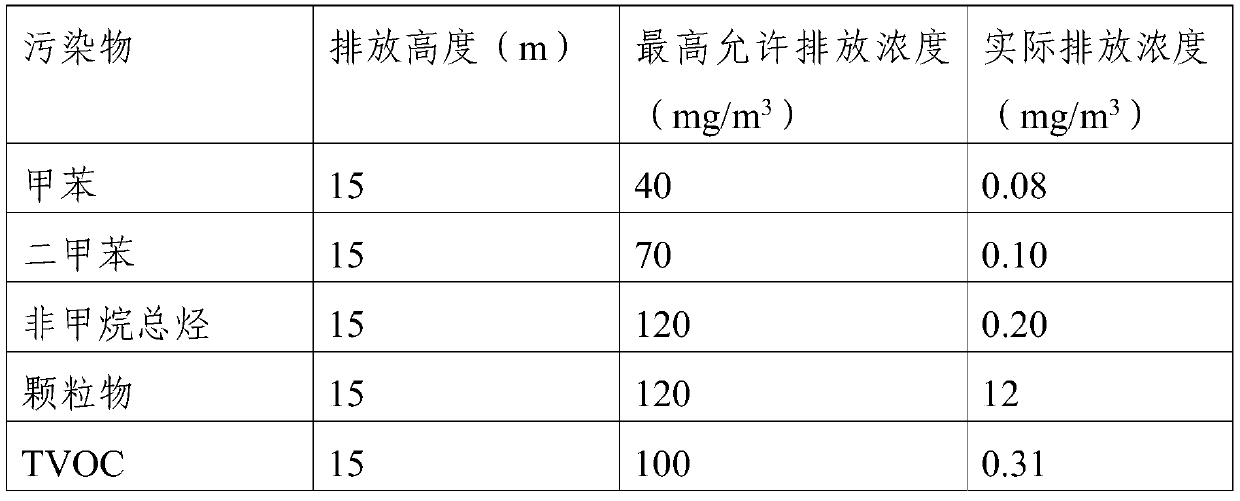

[0038] For example, if the method and system of Example 1 are run on a certain coating spraying line, the treatment cost can be saved by more than 80%, the exhaust gas can reach the standard stably, and the exhaust gas emissions are as follows:

[0039]

[0040] Waste residue emissions can be reduced by more than 90%:

[0041] By running this treatment method, the actual emission concentration of pollutants is far lower than the maximum allowable emission concentration standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com