Outside-furnace denitration system and method for breaking constraints of chemical bonds

A chemical bond and denitrification technology, which is applied in the field of flue gas denitrification treatment, can solve the problems of low out-of-stock efficiency and achieve the effects of increased Brownian motion speed, large molecular potential energy, and increased molecular potential energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

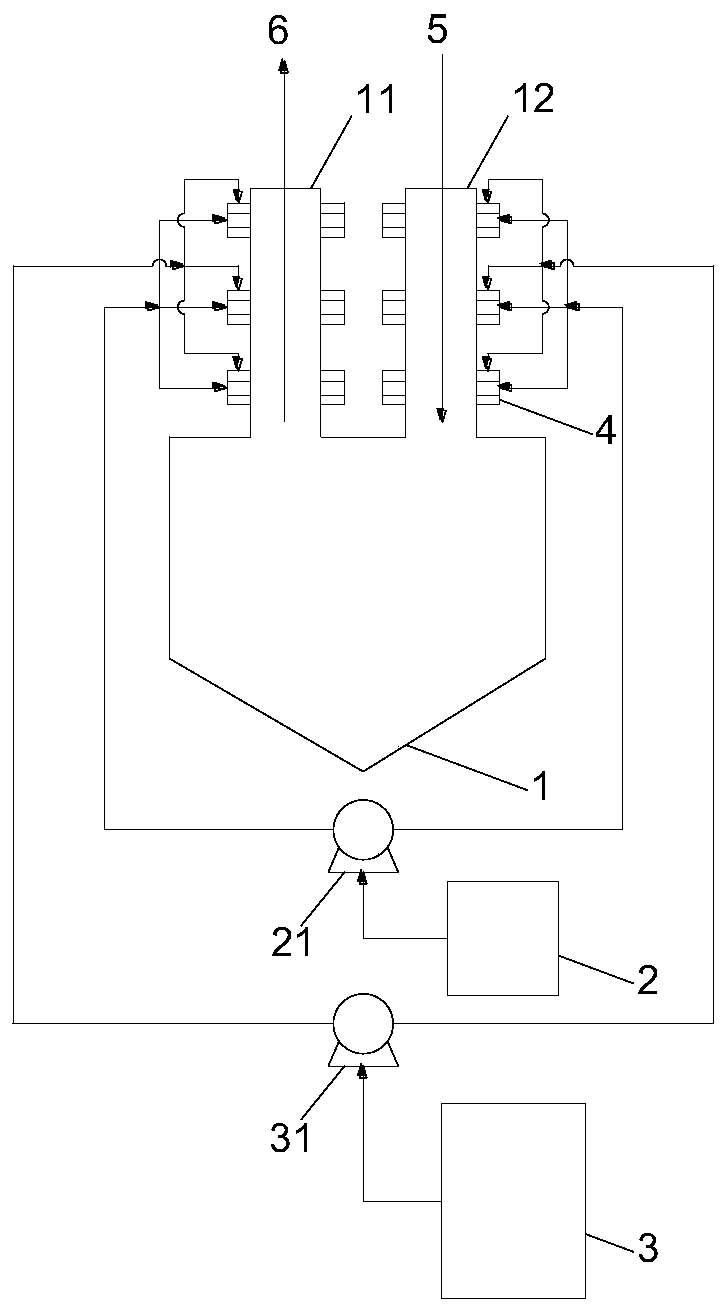

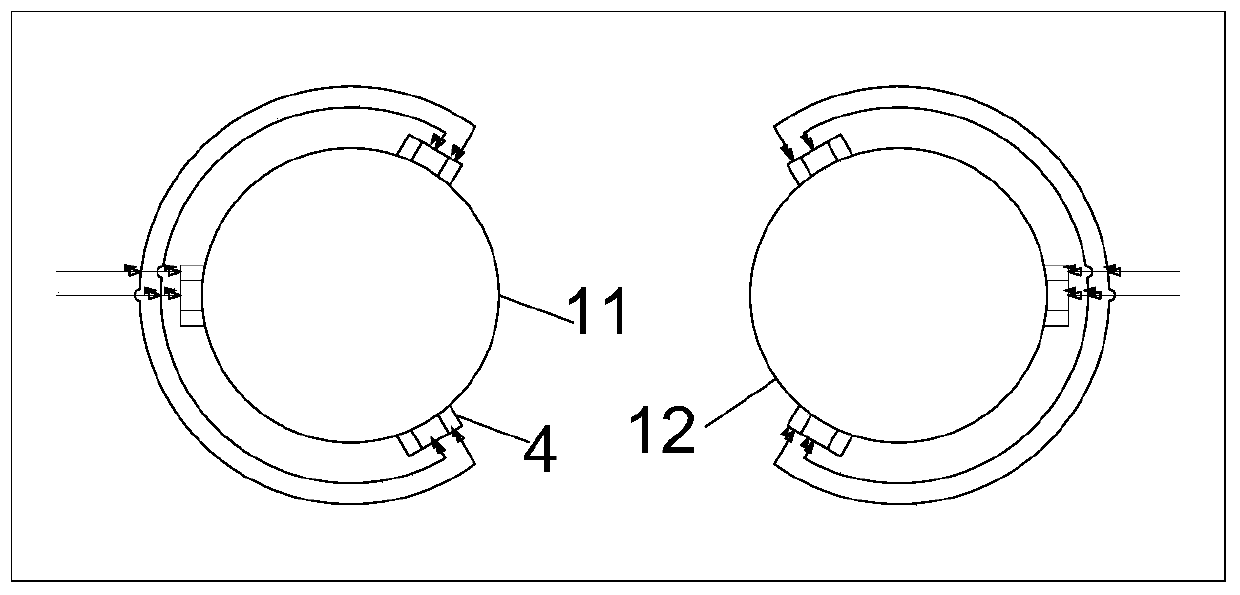

[0052] a): Add a denitration agent with a concentration ratio of 20% to the interior of the denitration agent storage tank 2, and add ammonia water to the interior of the steam boiler 3 at the same time, start the steam boiler 3 to produce high-temperature and high-pressure water vapor and high-temperature ammonia at a temperature of 190°C , the denitration agent, the high temperature and high pressure water vapor and the high temperature ammonia gas are transported to the inside of the denitration agent nozzle 4 through the denitrification agent delivery pump 21 and the steam delivery pump 31 respectively;

[0053] b): The denitrification agent nozzle 4 sprays the denitrification agent, high temperature and high pressure water vapor and high temperature ammonia into the interior of the denitrification agent inlet pipe 11 and the interior of the denitrification agent outlet pipe 12 at the same time. 3 The flue gas 5 of the coal-fired boiler enters the interior of the buffer tan...

Embodiment 2

[0056] a): Add a denitration agent with a concentration ratio of 20% to the interior of the denitration agent storage tank 2, and add ammonia water to the interior of the steam boiler 3 at the same time, start the steam boiler 3 to produce high-temperature and high-pressure water vapor and high-temperature ammonia at a temperature of 200°C , the denitrification agent, high temperature and high pressure water vapor and high temperature ammonia gas are transported to the interior of the denitrification agent nozzle 4 through the denitrification agent transfer pump 21 and the steam transfer pump 31 respectively;

[0057] b): The denitrification agent nozzle 4 injects the denitrification agent, high temperature and high pressure water vapor and high temperature ammonia into the interior of the denitrification agent inlet pipe 11 and the interior of the denitrification agent outlet pipe 12 at the same time. 3 The flue gas 5 of the coal-fired boiler is passed into the interior of the...

Embodiment 3

[0060] a): Add a denitration agent with a concentration ratio of 20% to the interior of the denitration agent storage tank 2, and add ammonia water to the interior of the steam boiler 3 at the same time, start the steam boiler 3 to produce high-temperature and high-pressure water vapor and high-temperature ammonia at a temperature of 210°C , the denitrification agent, high temperature and high pressure water vapor and high temperature ammonia gas are transported to the interior of the denitrification agent nozzle 4 through the denitrification agent transfer pump 21 and the steam transfer pump 31 respectively;

[0061] b): The denitration agent nozzle 4 sprays the denitration agent, high temperature and high pressure water vapor and high temperature ammonia gas into the denitration agent inlet pipe 11 and the denitration agent outlet pipe 12 at the same time, and at the same time, 150000m3 of coal-fired boiler flue gas 5 is discharged from the buffer tank 1 The inlet channel lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com