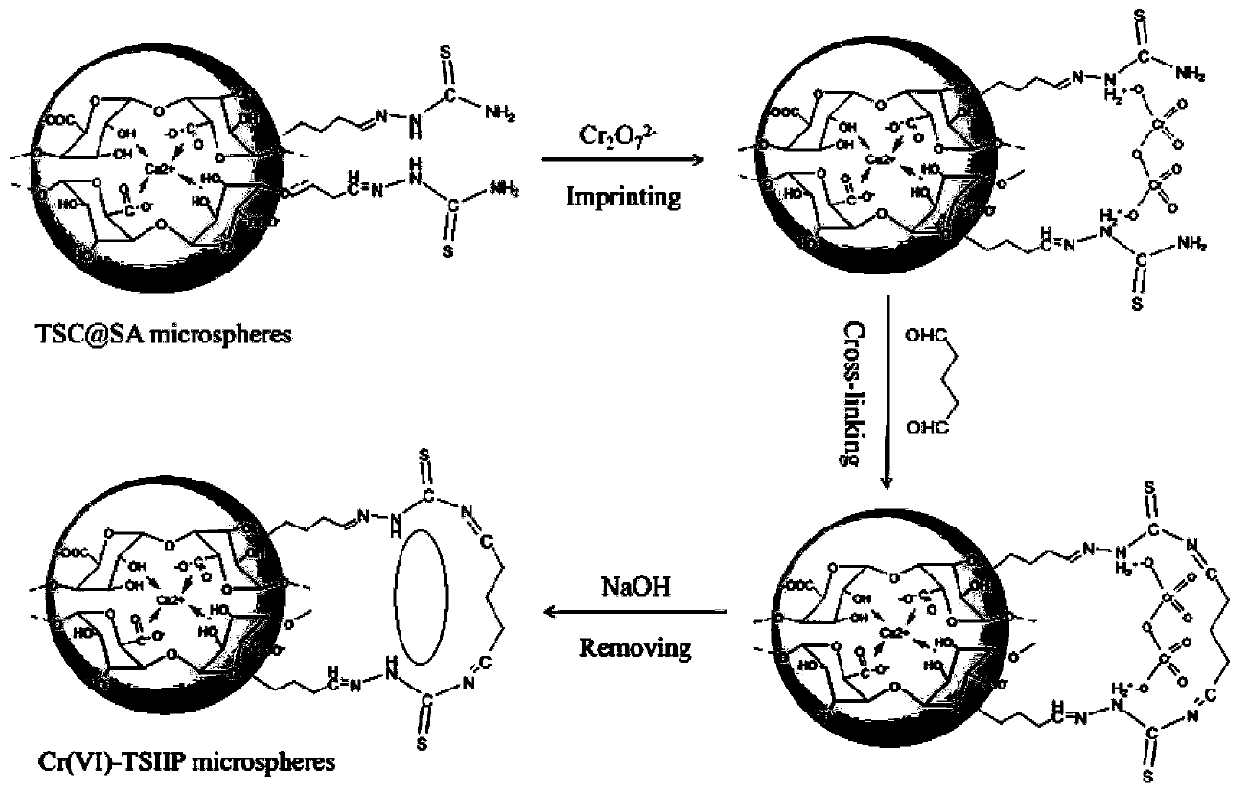

Microsphere adsorbent for highly selective adsorption of Cr(VI) and preparation method and application thereof

A highly selective, microsphere adsorption technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of non-selective and poor adsorbents, and improve imprinting efficiency and adsorption. speed, high adsorption capacity, and the effect of avoiding difficult elution of template ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Dissolve 2g of sodium alginate powder in 100mL of deionized water to prepare a 2wt% sodium alginate solution, and then add it dropwise to 100mL of 1wt% CaCl 2 In the solution, stir while adding, drop completely within 2 hours, and the magnetic stirring speed is 300rpm; cross-link at room temperature for 7 hours, filter, and wash repeatedly with deionized water to obtain gelatinous sodium alginate microspheres;

[0057] (2) Then drop the above-mentioned gelatinous sodium alginate microspheres into 50mL of thiosemicarbazide aqueous solution containing glutaraldehyde, wherein the mol ratio of sodium alginate repeating structural unit, glutaraldehyde, and thiosemicarbazide is 1: 1:1, add hydrochloric acid to adjust the pH of the solution to 4-5, keep the temperature at 65°C, and react with magnetic stirring for 6 hours at a magnetic stirring speed of 600rpm; filter and wash repeatedly with deionized water to obtain thiosemicarbazide-modified sodium alginate microspheres;...

Embodiment 2

[0066] (1) Dissolve 2g of sodium alginate powder in 100mL of deionized water to prepare a 2wt% sodium alginate solution, and then add it dropwise to 100mL of 1wt% CaCl 2 In the solution, stir while adding, drop completely within 1 hour, the magnetic stirring speed is 500rpm; cross-link at room temperature for 6 hours, filter, and wash repeatedly with deionized water to obtain gelatinous sodium alginate microspheres;

[0067] (2) Then the above-mentioned gelatinous sodium alginate microspheres are dropped into 60mL of thiosemicarbazide aqueous solution containing glutaraldehyde, wherein the mol ratio of sodium alginate repeating structural unit, glutaraldehyde, and thiosemicarbazide is 2: 1:1, add hydrochloric acid to adjust the pH of the solution to 4-5, keep the temperature at 60°C, and react with magnetic stirring for 5 hours at a magnetic stirring speed of 500rpm; filter and wash repeatedly with deionized water to obtain thiosemicarbazide-modified sodium alginate microsphere...

Embodiment 3

[0076] (1) Dissolve 2g of sodium alginate powder in 100mL of deionized water to prepare a 2wt% sodium alginate solution, and then add it dropwise to 100mL of 1wt% CaCl 2 In the solution, stir while adding, drop completely within 2 hours, the magnetic stirring speed is 400rpm; cross-link at room temperature for 6 hours, filter, and wash repeatedly with deionized water to obtain gelatinous sodium alginate microspheres;

[0077] (2) Then drop the above-mentioned gelatinous sodium alginate microspheres into 70mL of thiosemicarbazide aqueous solution containing glutaraldehyde, wherein the mol ratio of sodium alginate repeating structural unit, glutaraldehyde, and thiosemicarbazide is 1: 1:1, add hydrochloric acid to adjust the pH of the solution to 4-5, keep the temperature at 65°C, and react with magnetic stirring for 6 hours at a magnetic stirring speed of 600rpm; filter and wash repeatedly with deionized water to obtain thiosemicarbazide-modified sodium alginate microspheres;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com