In-situ-doped iron-based Fenton-like catalyst and synthesis method and application thereof

A technology of in-situ doping and synthesis methods, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as poor stability, low utilization rate of hydrogen peroxide, poor activity, etc., to achieve Good stability, easy to separate from water, strong chemical adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

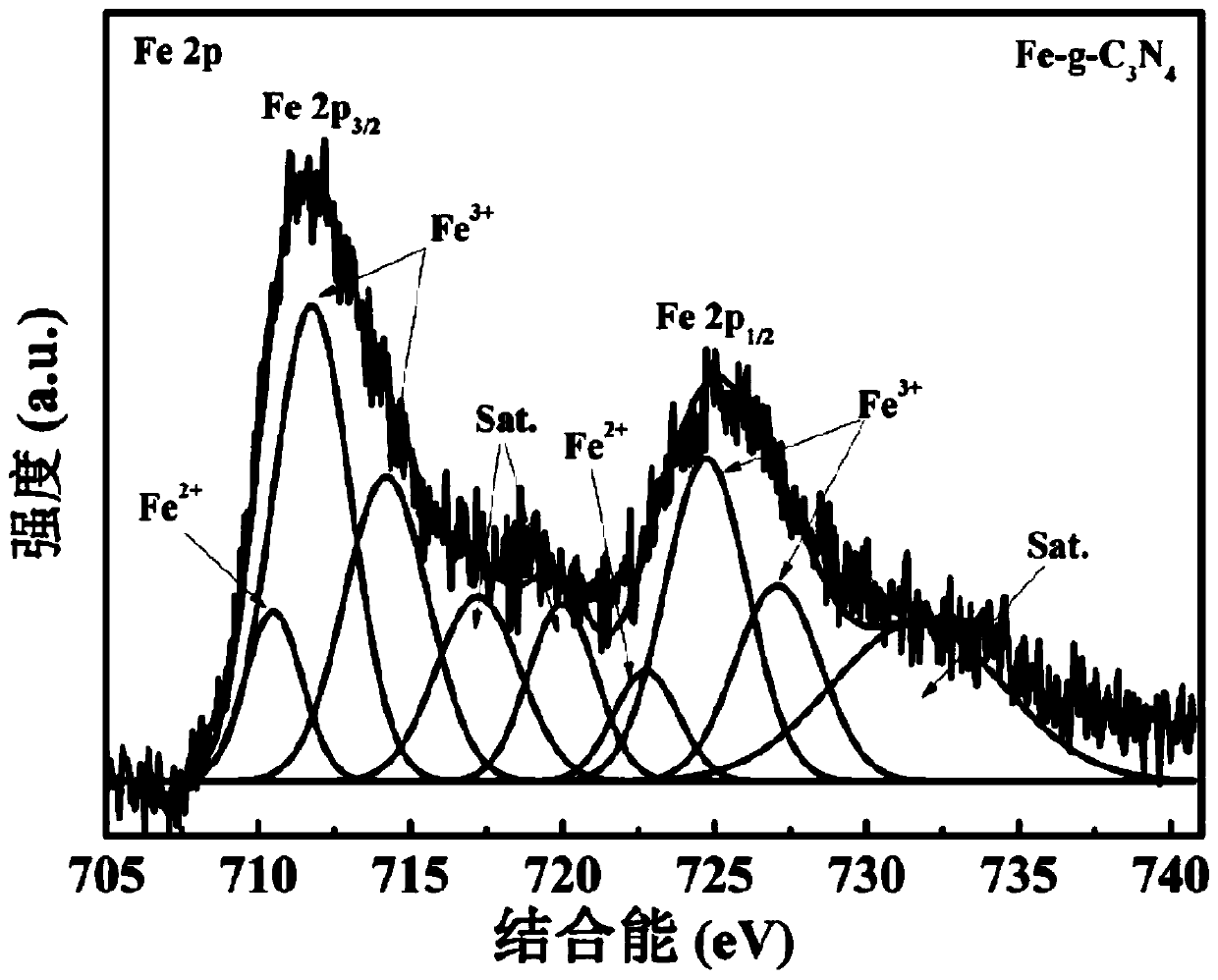

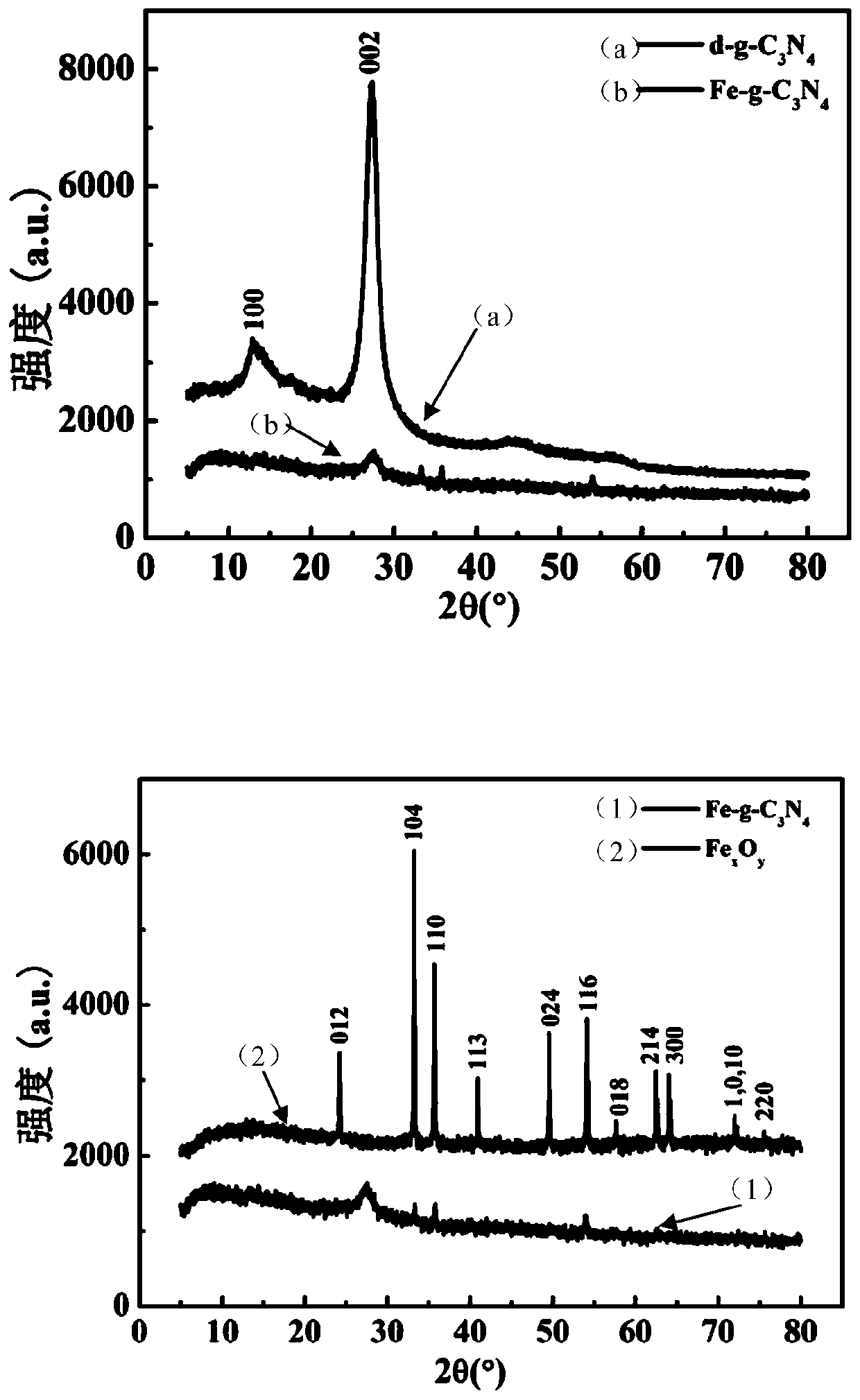

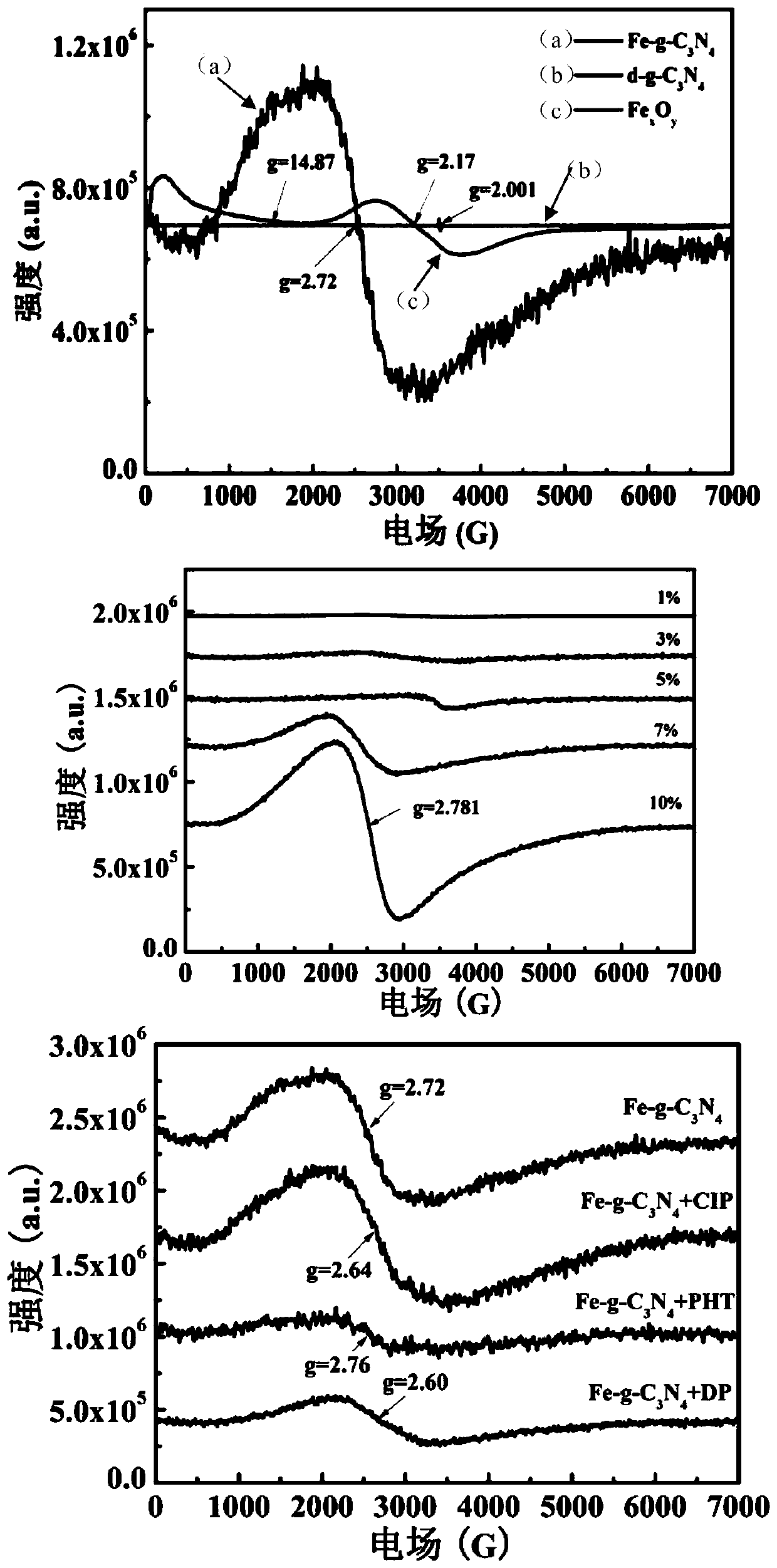

[0040] In-situ doped iron-based Fenton-like catalyst Fe-g-C of the present invention 3 N 4 The synthetic method comprises the following steps:

[0041] (1) 1.07g ferric chloride hexahydrate (FeCl 3 ·6H 2 O) Dissolve in 25mL of water, place the beaker on a 70°C collector type constant temperature heating magnetic stirrer in a water bath and stir for 30min to form solution A.

[0042] (2) 5g melamine (C 3 N 3 (NH 2 ) 3 ) Grind evenly to fine powder, and gradually add to solution A to form solution B.

[0043] (3) The solution B was placed on a magnetic stirrer with a collector type constant temperature heating at 70° C. and evaporated to dryness in a water bath to obtain a solid product A.

[0044] (4) Put the solid product A in an oven at 70°C for 8 hours, and then grind it evenly for later use.

[0045] (5) Put the solid powder uniformly ground in step (4) into a muffle furnace and roast at 550°C for 2h at a heating rate of 5°C / min, and cool naturally to obtain an in-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com