FePt-MgO magnetic recording film and preparation method thereof

A magnetic recording and thin-film technology, which is applied in the direction of coating with magnetic layers, disc carrier manufacturing, sputtering coating coating, etc., can solve the problem that crystal grains cannot be completely separated from each other, which is not conducive to magnetic storage density, and reduces the size of magnetic devices and other problems, to achieve the effect of free self-organized growth process, not easy to fall off, and reduce the size of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

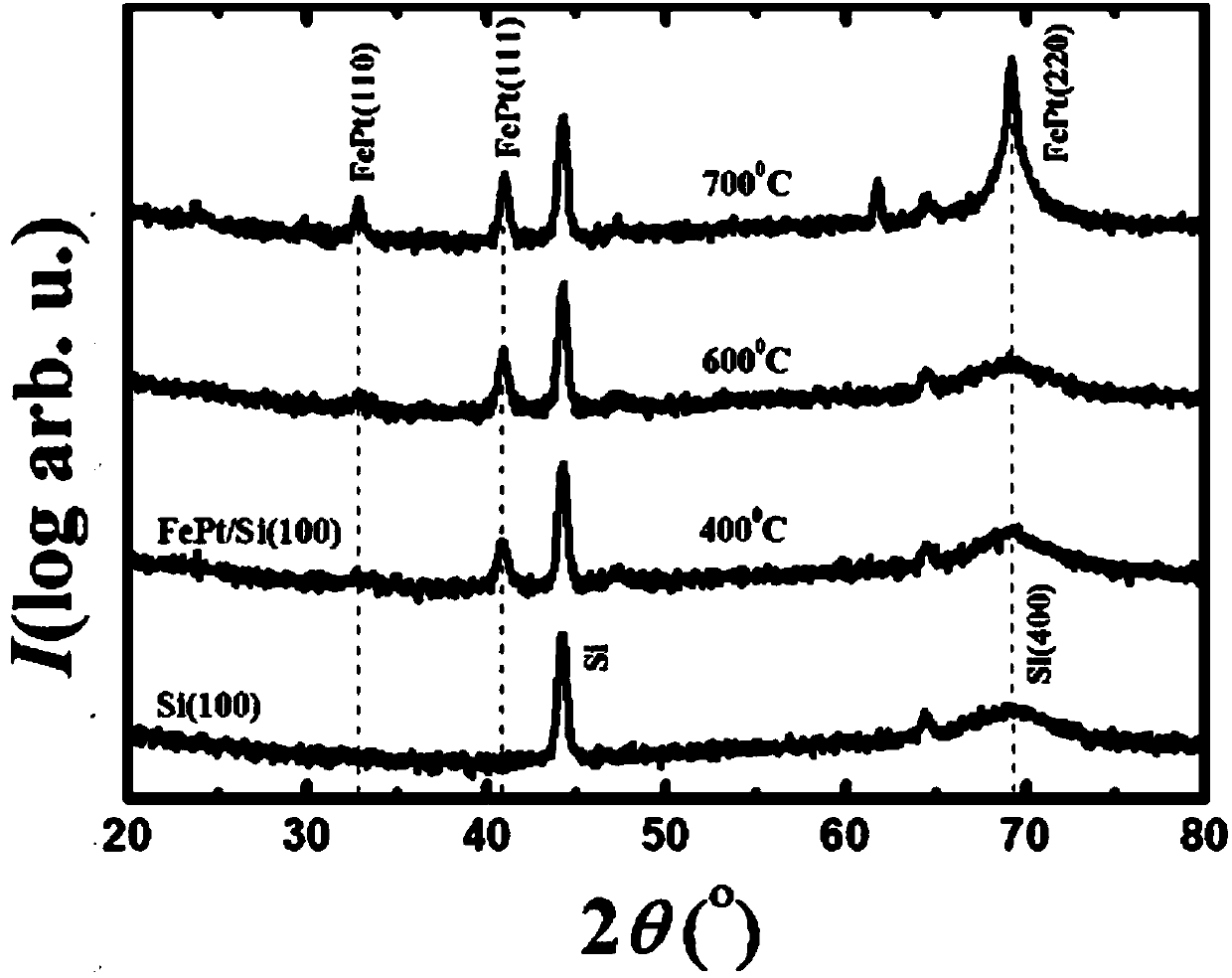

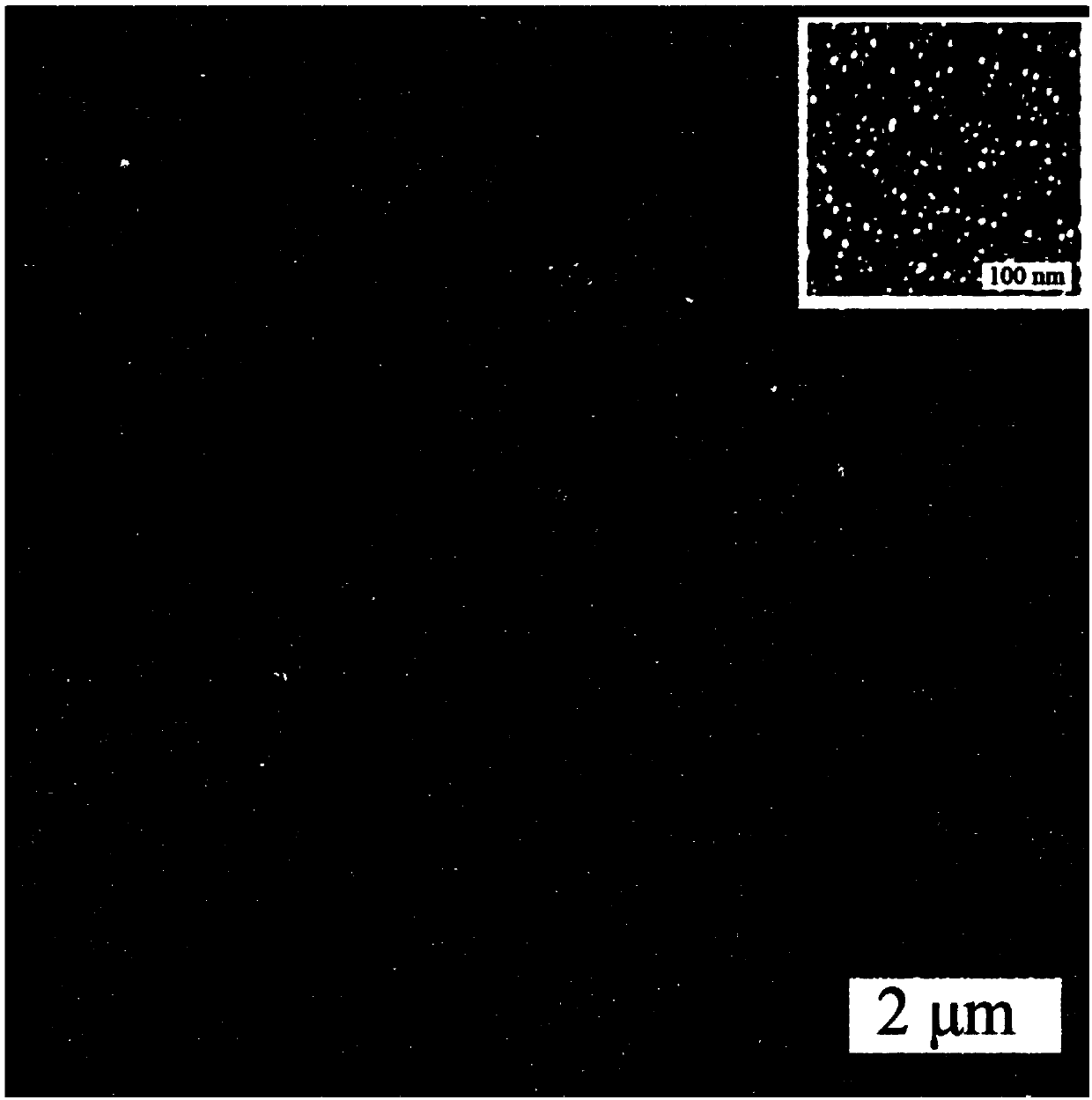

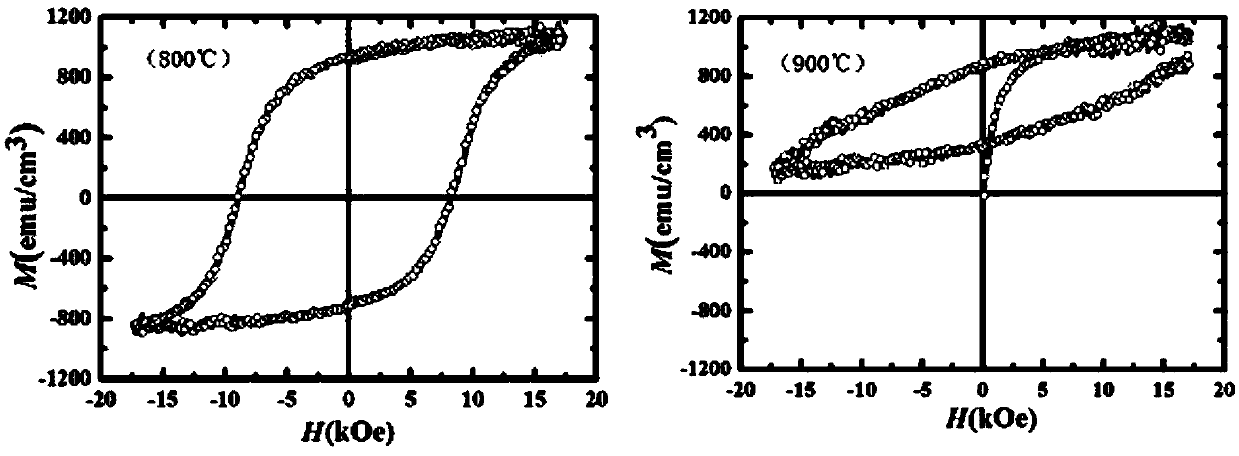

[0033] Embodiment one, a kind of FePt-MgO magnetic recording thin film, by substrate, be deposited on the pad layer on described substrate and be deposited on the magnetic layer on described pad layer, described substrate is Si substrate, described pad The layer is an MgO cushion layer, and the magnetic layer includes an MgO embedding layer and an array of FePt nano-tables embedded in the MgO embedding layer. One end of the FePt nano-tables is fixed on the MgO cushion layer, and the other end protrudes from the membrane. noodle. The thickness of the MgO cushion layer is 10nm. The atomic ratio of Fe and Pt in the magnetic layer is 1:1; the thickness of the MgO embedded layer is 1-5nm.

Embodiment 2

[0034] Embodiment two, a kind of preparation method of FePt-MgO magnetic recording film, it comprises the following steps:

[0035]1) Prepare the MgO cushion layer, use the Si single crystal with the orientation of (100) as the substrate, clean it in acetone and alcohol with an ultrasonic device, and dry it with compressed air, and put the dried Si substrate into the substrate with tweezers Sample holder, the sample holder is transferred from the sampling chamber to the magnetron sputtering chamber by a robot, and a 10nm thick MgO cushion layer is deposited on the substrate by vacuum magnetron sputtering coating method; the temperature of the Si substrate during sputtering is 100°C , the background vacuum of the sputtering chamber is 2×10 -5 Pa, the argon gas pressure is 2.8Pa.

[0036] 2) Prepare the magnetic layer, and use the magnetron sputtering method to alternately sputter the FePt-MgO mixed layer and the MgO embedded layer on the MgO underlayer prepared in step 1), and...

Embodiment 3

[0039] Embodiment three, a kind of preparation method of FePt-MgO magnetic recording film, it comprises the following steps:

[0040] 1) Prepare the MgO cushion layer, use Si(100) single crystal as the substrate, clean it in acetone and alcohol with an ultrasonic device, and dry it with compressed air, put the dried Si substrate into the sample holder with tweezers, The sample holder is transferred from the sampling chamber to the magnetron sputtering chamber by a robot, and a 10nm thick MgO cushion layer is deposited on the substrate by vacuum magnetron sputtering coating method; the temperature of the Si substrate is 100°C during sputtering, and the The back vacuum of the cavity is 2×10 -5 Pa, the argon gas pressure is 2.8Pa.

[0041] 2) Prepare the magnetic layer, and use the magnetron sputtering method to alternately sputter the FePt-MgO mixed layer and the MgO embedded layer on the MgO underlayer prepared in step 1), and obtain the substrate, the MgO underlayer, the FePt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com