Ginkgo polysaccharide functional candy and preparation method thereof

A ginkgo polysaccharide and functional technology, applied in the field of food processing, can solve problems such as unreported, and achieve the effects of widening the scope of application, good immune regulation, good economic benefits and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of ginkgo polysaccharide: select fresh ginkgo without mildew and hard core, dry, crush, and pass through a 60-mesh sieve; use ultrasonic-assisted water extraction and alcohol precipitation method to extract, according to the ratio of material to water 1:20, heat treatment at 50°C and 150W The extract was obtained in 50 minutes, and the polysaccharide in the extract was precipitated with 60% ethanol, washed and dried to obtain crude polysaccharide.

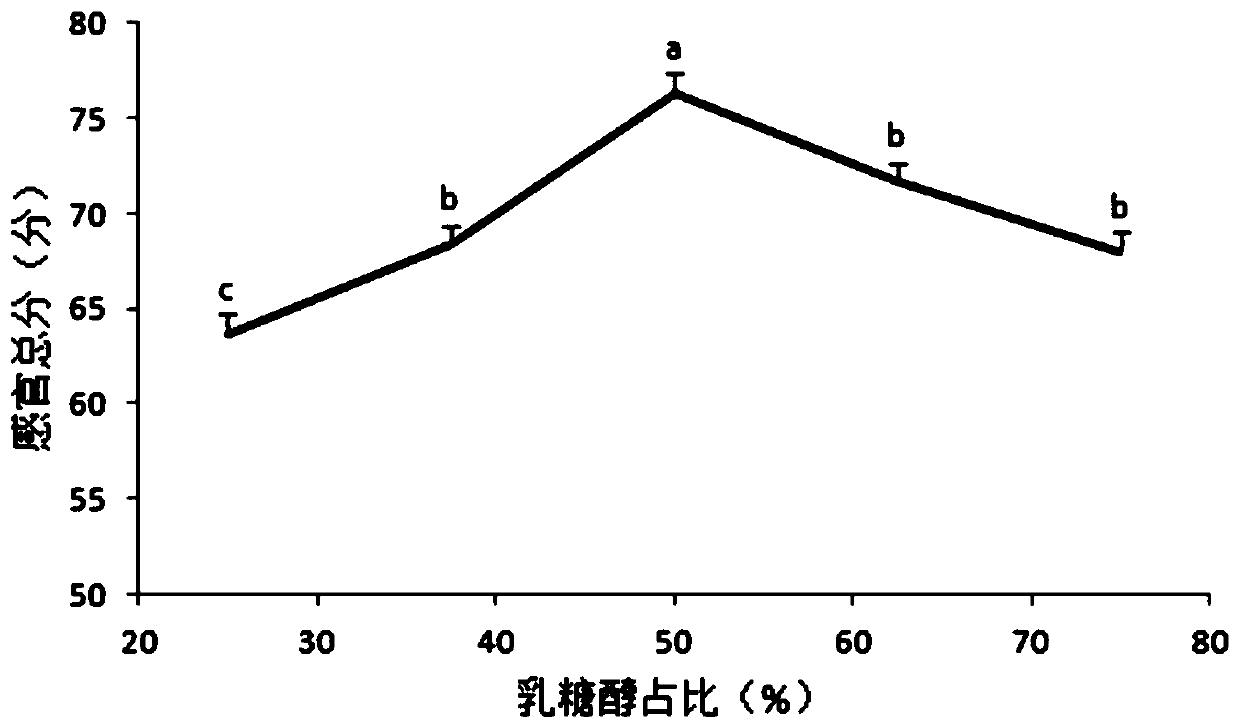

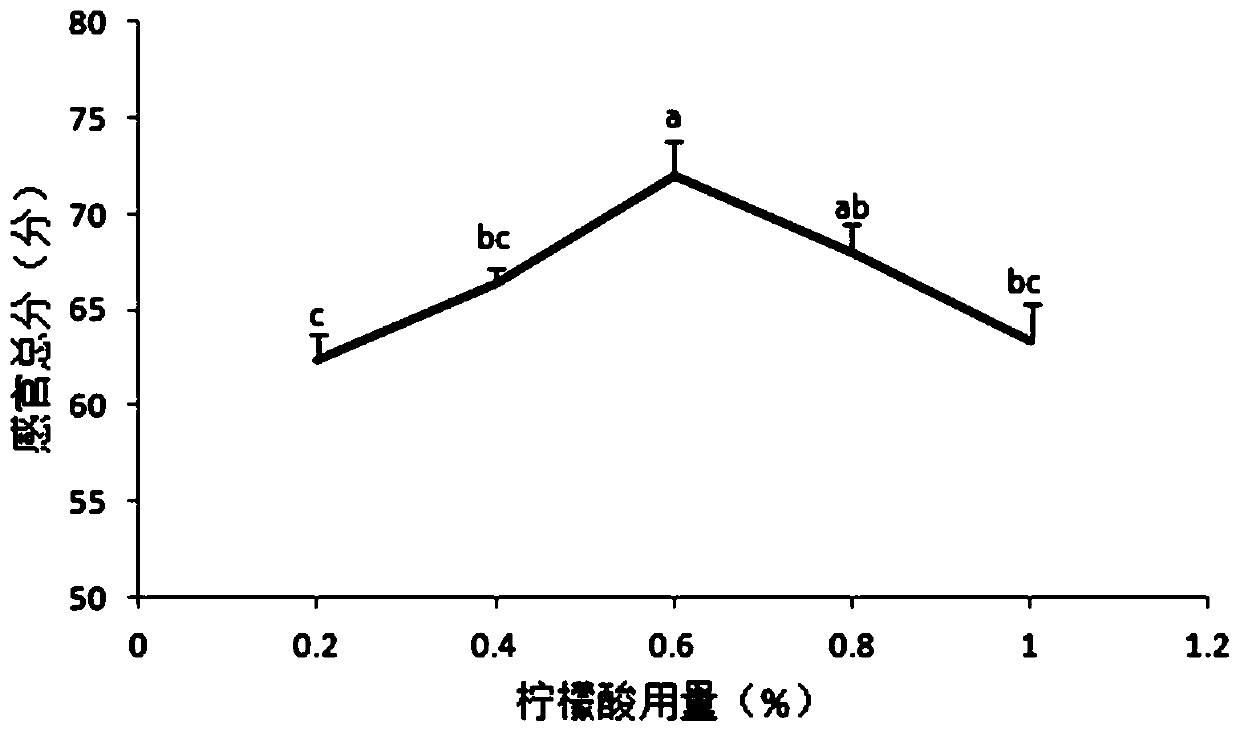

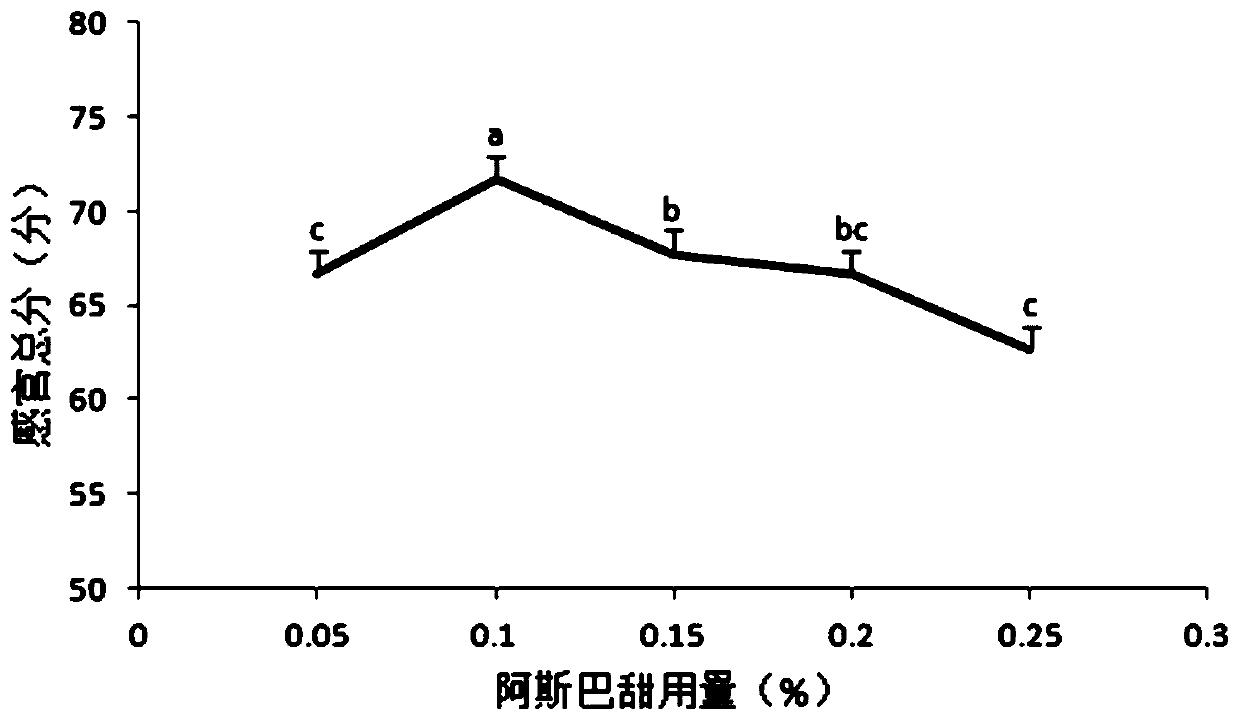

[0032] Preparation of ginkgo polysaccharide functional candy: dissolve isomaltooligosaccharide and lactitol in water, boil, add ginkgo polysaccharide, citric acid, and aspartame, pour into a mold, cool and set, release the mold and package the finished product. The mixture of isomaltooligosaccharide and lactitol is fully dissolved in water and then heated until the sugar solution is clear and transparent, and the bubbles become smaller. Stop heating when dipping the filament with a shovel to keep drawing it; Stir...

Embodiment 2

[0034] In this example, isomaltooligosaccharide and lactitol are mixed in a mass ratio of 1:3, fully dissolved in water, and then heated continuously with stirring until the sugar solution is clear and transparent, and the bubbles become smaller. Stop heating; When the isomaltooligosaccharide and lactitol sugar liquid are boiled to start to produce bubbles, add the solution that the ginkgo crude polysaccharide with a quality of 0.2% of the total mass of isomaltooligosaccharide and lactitol is made; When the temperature drops to 80-90°C, add 0.4% citric acid and 0.1% aspartame whose mass is the total mass of isomaltooligosaccharide and lactitol for blending; pour the blended syrup into the mold to cool and shape it, and release the mold. The finished product is packaged after removing irregular sugar lumps. The prepared candy is relatively hard.

Embodiment 3

[0036] In this example, isomaltooligosaccharide and lactitol are mixed in a mass ratio of 1:1, fully dissolved in water, and then heated continuously with stirring until the sugar solution is clear and transparent, and the bubbles become smaller. Stop heating; When the isomaltooligosaccharide and lactitol sugar liquid are boiled to start to produce bubbles, add the solution that the ginkgo crude polysaccharide with a quality of 0.2% of the total mass of isomaltooligosaccharide and lactitol is made; When the temperature drops to 80-90°C, add 0.1% citric acid and 0.1% aspartame whose mass is the total mass of isomalto-oligosaccharide and lactitol for blending; pour the blended syrup into the mold to cool and shape it, and release the mold. The finished product is packaged after removing irregular sugar lumps. The sweetness of the prepared candy is too much.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com