High-temperature and high-enthalpy phase change material microcapsule with multiwall structure, and preparation method thereof

A technology of phase change materials and wall structures, applied in heat exchange materials, chemical instruments and methods, layered products, etc., to achieve the effects of improving service life, overcoming difficulties in recycling, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

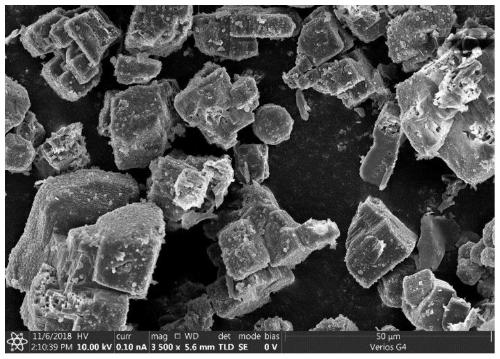

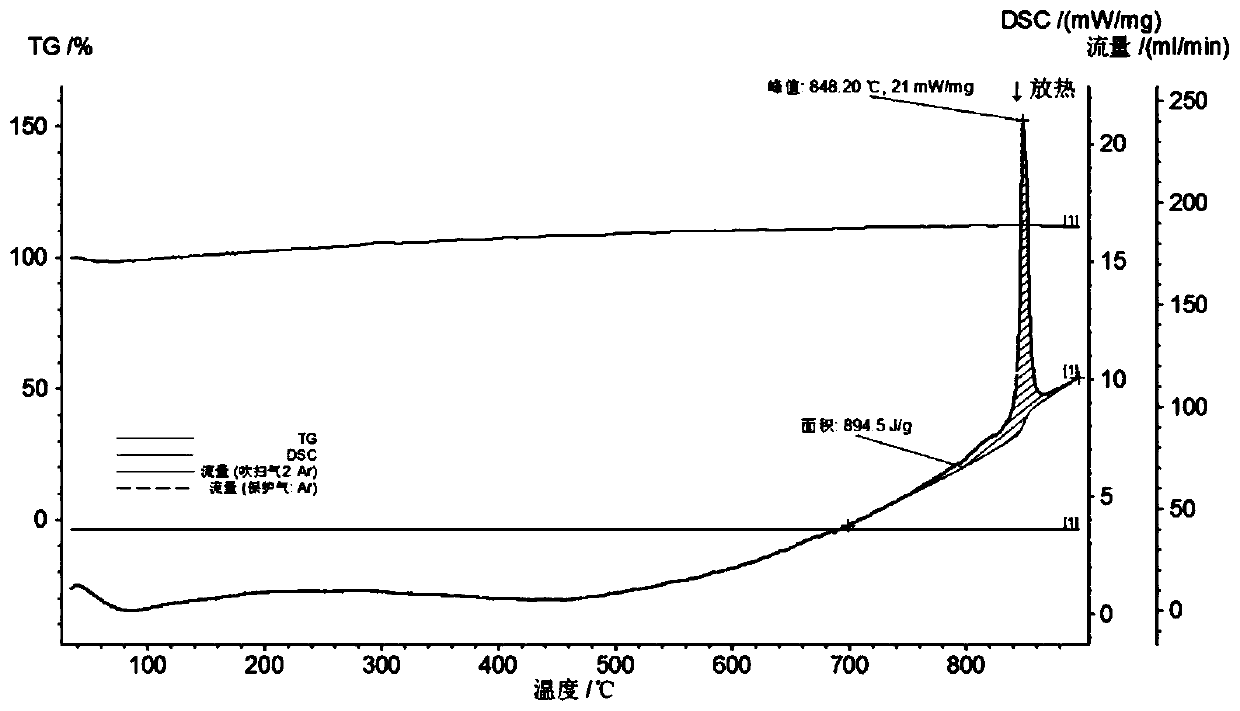

[0023] Example 1: Polyurethane is used as a volume expansion buffer layer, graphene oxide is used as an anti-corrosion layer and a polyborosilazane precursor is used as a high-temperature resistant strength layer to coat a high-temperature phase change material sodium chloride

[0024] Use a 400-mesh filter to screen out 5g of sodium chloride, add it to 10g of polyurethane system, and emulsify at high speed for 30 minutes to obtain particles coated with polyurethane on the surface, then disperse the obtained particles into 200ml of water phase, transfer them to a 500ml three-necked flask, and add 1.6g (1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride) and 0.5g N-hydroxysuccinimide, after activation for 30min, add 50ml dropwise with a constant pressure funnel, Graphene oxide aqueous solution with a solid content of 0.5% was reacted for 12 hours at 70° C. at a rotational speed of 200 rpm, centrifuged and washed three times, and freeze-dried. Then, by solvent extractio...

Embodiment 2

[0025] Example 2: Polydopamine is used as a volume expansion buffer layer, graphene is used as an anti-corrosion layer, and silicon dioxide is used as a high-temperature resistant strong layer to coat the high-temperature phase change material lithium fluoride

[0026] Use a 200-mesh filter to screen out 20g of lithium fluoride and 5g of dopamine hydrochloride, add it to 500ml of aqueous solution with pH=8.5, transfer it to a 1000ml three-necked flask, and react at 30°C with a rotation speed of 100rpm for 24 hours, then centrifuge, wash and dry . The obtained product repeats the above operation, so that the polydopamine layer reaches a certain thickness. The obtained two-layer polydopamine-coated lithium fluoride particles were dispersed into 500 ml of graphene oxide aqueous solution with a solid content of 0.05%, at a rotation speed of 150 rpm, at 60 degrees Celsius, for 18 hours, centrifuged and washed three times, and freeze-dried. Then adopt the sol-gel method, take 5g dr...

Embodiment 3

[0027] Example 3: Polyurethane is used as a volume expansion buffer layer, graphene oxide is used as an anti-corrosion layer and a polyborosiloxane precursor is used as a high-temperature resistant strong layer to coat a high-temperature phase change material lithium chloride

[0028] Use a 200-mesh filter to screen out 5g of lithium chloride, add it to 10g of polyurethane system, and emulsify at high speed for 30 minutes to obtain particles coated with polyurethane on the surface, then disperse the obtained particles into 200ml of water phase, transfer them to a 500ml three-necked flask, and add 1.6g (1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride) and 0.5g N-hydroxysuccinimide, after activation for 30min, add 50ml dropwise with a constant pressure funnel, Graphene oxide aqueous solution with a solid content of 0.5% was reacted for 12 hours at 70° C. at a rotational speed of 200 rpm, centrifuged and washed three times, and freeze-dried. Then, by solvent extractio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com