Method for jointly treating polluted sludge by electroosmosis and solidification

A combined treatment and electroosmotic treatment technology, applied in the direction of electrochemical sludge treatment, fixed/solidified sludge treatment, chemical instruments and methods, etc., can solve the problems of large amount of curing agent, long construction time, secondary pollution, etc. , to achieve the effect of low construction cost, good curing effect, and short time-consuming electroosmosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

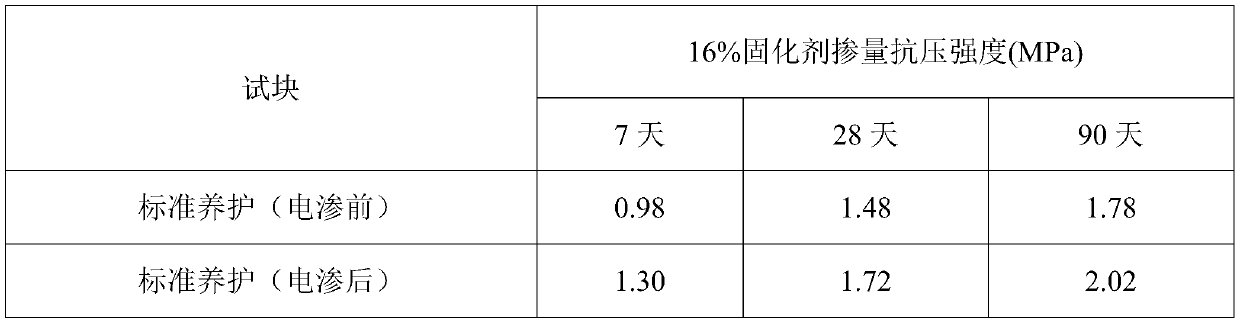

Embodiment 1

[0044] A method for electroosmotic solidification combined treatment of polluted sludge, it comprises the following steps:

[0045] 1) pull out the polluted sludge, filter and remove the water on the surface of the polluted sludge, and obtain the pretreated sludge;

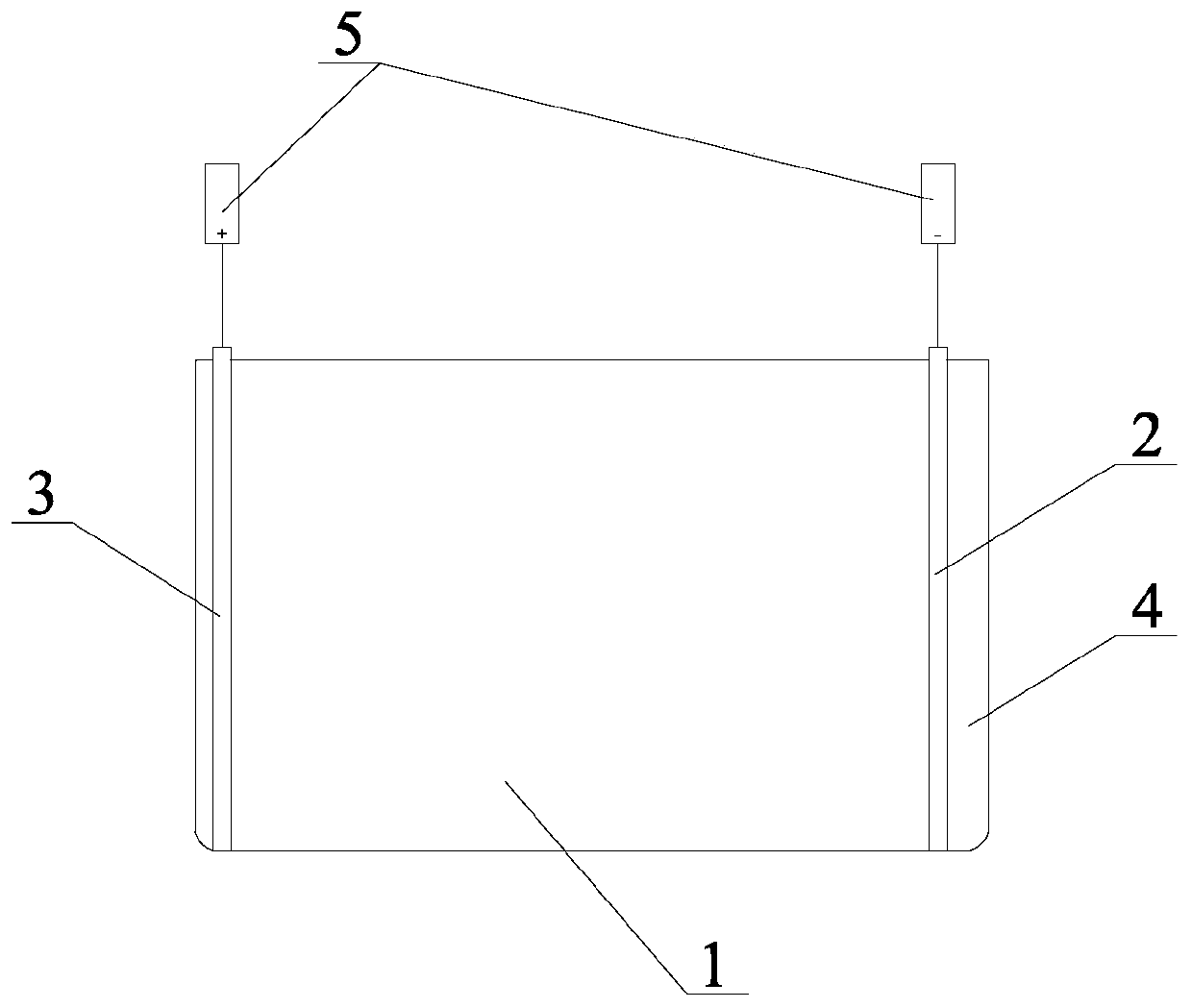

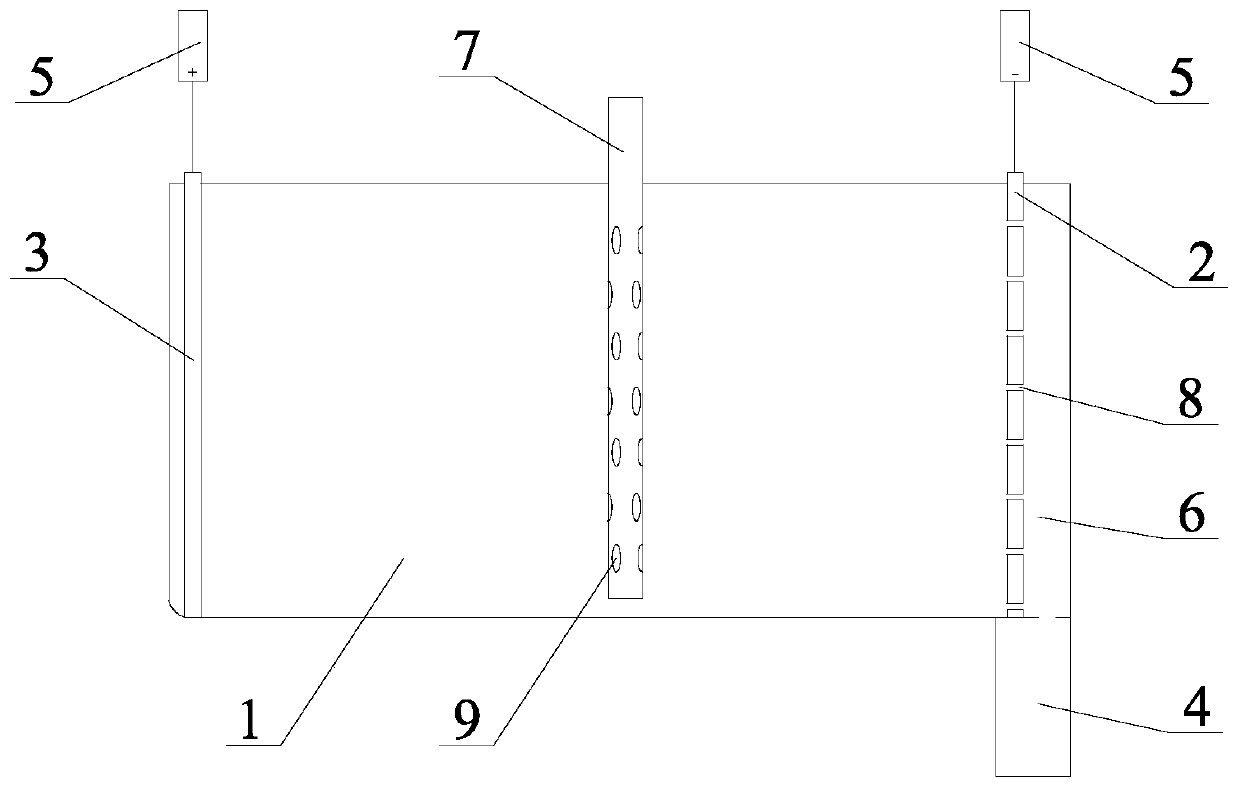

[0046] 2) Fill the pretreated sludge into the electroosmotic device for electroosmotic treatment until the required water content is reached; the electroosmotic device includes a treatment pool 1, an electrode, a DC power supply 5 and wires, and the electrode includes a The cathode 2 on the side wall and the anode 3 located on the right side wall of the treatment tank 1, the cathode 2 and the anode 3 are respectively connected to the DC power supply 5 through wires; the electroosmosis treatment refers to turning on the DC power supply 5 to make the Water and heavy metal ions are transported from the anode 3 to the cathode 2; there is no need to use a water pump if there is no special need, and the drainage process...

Embodiment 2

[0053] A method for electroosmotic solidification combined treatment of polluted sludge, it comprises the following steps:

[0054] 1) pull out the polluted sludge, filter and remove the water on the surface of the polluted sludge, and obtain the pretreated sludge;

[0055] 2) Fill the pretreated sludge into the electroosmotic device for electroosmotic treatment until the required water content is reached; the electroosmotic device includes a treatment pool 1, an electrode, a DC power supply 5 and wires, and the electrode includes a The cathode 2 on the side wall and the anode 3 located on the right side wall of the treatment tank 1, the cathode 2 and the anode 3 are respectively connected to the DC power supply 5 through wires; the electroosmosis treatment refers to turning on the DC power supply 5 to make the Water and heavy metal ions move from the anode 3 to the cathode 2;

[0056] 3) Take out the electrodes of the electroosmosis device, add a curing agent into the treatm...

Embodiment 3

[0062] A method for electroosmotic solidification combined treatment of polluted sludge, the difference from Example 1 is that the curing agent is made of the following components in parts by weight: 30 parts of sulphoaluminate cement, 35 parts of sodium hydroxide , 20 parts of sodium silicate, 5 parts of hydrogen peroxide, and 1 part of triethanolamine. The dosage of the curing agent is 8% of the mass of the sludge after electroosmosis treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com