A kind of concrete waterproof anti-cracking agent and preparation method thereof

A technology of anti-cracking agent and concrete, which is applied in the field of concrete admixtures, can solve the problems of small amount of concrete waterproofing and anti-cracking agent, low preparation cost, and low equipment dependence, and achieve great promotion and application value, low preparation cost, and equipment less dependent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

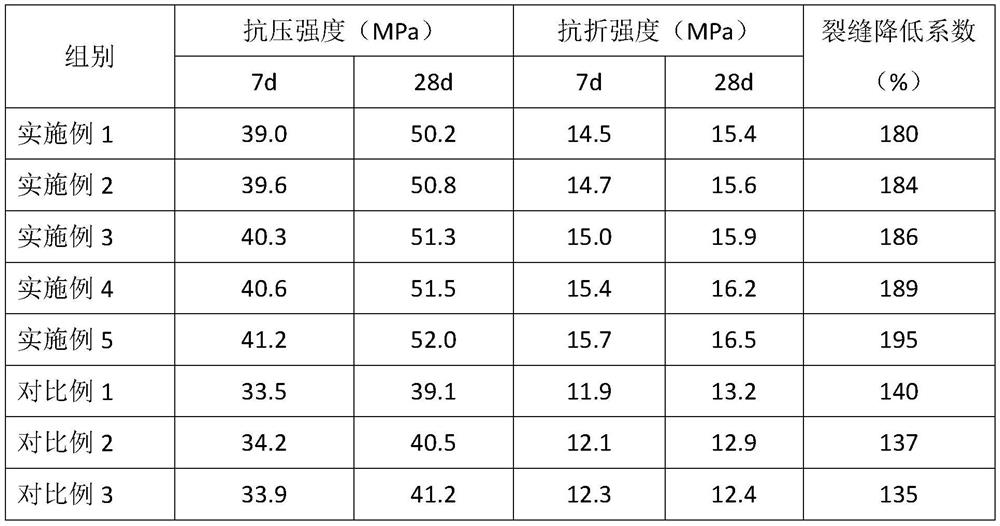

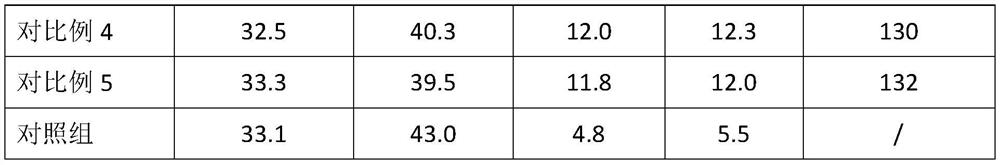

Examples

Embodiment 1

[0030] A concrete waterproof anti-cracking agent, made of the following raw materials in parts by weight: 20 parts of surface-soluble polymer modified expansion components, 2-carboxyethyl-bis(2-hydroxyethyl)-[3-(2, 2,3,3,4,4,5,5,6,6,7,7,8,8,8-Pentadecafluorooctanoylamino)propyl]ammonium hydroxide modified rare earth oxide nanostructured fibers 3 parts, chloromethylphenethyltris(trimethylsiloxy)silane ionized N,N'-[1,2-ethanediylbis[oxy(4-fluoro-2,1-phenyl)] ]5 parts of bis[N-(carboxymethyl)glycine], 5 parts of aluminum silicate fiber, 3 parts of waste gypsum, and 2 parts of polyacrylonitrile fiber.

[0031] The expansion component is prepared by mixing the following components by weight: 5 parts of alumite, 1 part of quicklime, 2 parts of magnesium oxide, 3 parts of kyanite, and 2 parts of magnesium aluminum silicate.

[0032] The preparation method of the surface-soluble polymer modified expansion component comprises the following steps: dispersing the expansion component in...

Embodiment 2

[0039] A concrete waterproof anti-cracking agent, made of the following raw materials in parts by weight: 23 parts of surface-soluble polymer modified expansion components, 2-carboxyethyl-bis(2-hydroxyethyl)-[3-(2, 2,3,3,4,4,5,5,6,6,7,7,8,8,8-Pentadecafluorooctanoylamino)propyl]ammonium hydroxide modified rare earth oxide nanostructured fibers 5 parts, chloromethylphenethyltris(trimethylsiloxy)silane ionized N,N'-[1,2-ethanediylbis[oxy(4-fluoro-2,1-phenyl)] ] 7 parts of bis[N-(carboxymethyl) glycine], 7 parts of aluminum silicate fiber, 5 parts of waste gypsum, and 3 parts of polyacrylonitrile fiber.

[0040] The expansion component is prepared by mixing the following components by weight: 6 parts of alumite, 2 parts of quicklime, 3 parts of magnesium oxide, 4 parts of kyanite, and 3 parts of magnesium aluminum silicate.

[0041] The preparation method of the surface-soluble polymer modified expansion component comprises the following steps: dispersing the expansion component...

Embodiment 3

[0048] A concrete waterproof anti-cracking agent, made of the following raw materials in parts by weight: 25 parts of surface-soluble polymer modified expansion components, 2-carboxyethyl-bis(2-hydroxyethyl)-[3-(2, 2,3,3,4,4,5,5,6,6,7,7,8,8,8-Pentadecafluorooctanoylamino)propyl]ammonium hydroxide modified rare earth oxide nanostructured fibers 6 parts, chloromethylphenethyltris(trimethylsiloxy)silane ionized N,N'-[1,2-ethanediylbis[oxy(4-fluoro-2,1-phenyl)] ] 8 parts of [N-(carboxymethyl) glycine], 8 parts of aluminum silicate fiber, 6 parts of waste gypsum, and 3.5 parts of polyacrylonitrile fiber.

[0049] The expansion component is prepared by mixing the following components by weight: 8 parts of alumite, 2 parts of quicklime, 3.5 parts of magnesium oxide, 4.5 parts of kyanite, and 3.5 parts of magnesium aluminum silicate.

[0050] The preparation method of the surface-soluble polymer modified expansion component comprises the following steps: dispersing the expansion comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com