LDMOS device resistant to total dose effect

An anti-total dose and effect technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of reducing gate oxygen high voltage tolerance, affecting device performance, device performance parameter degradation and failure, etc., to improve the total dose reinforcement ability. , the effect of suppressing threshold voltage drift and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

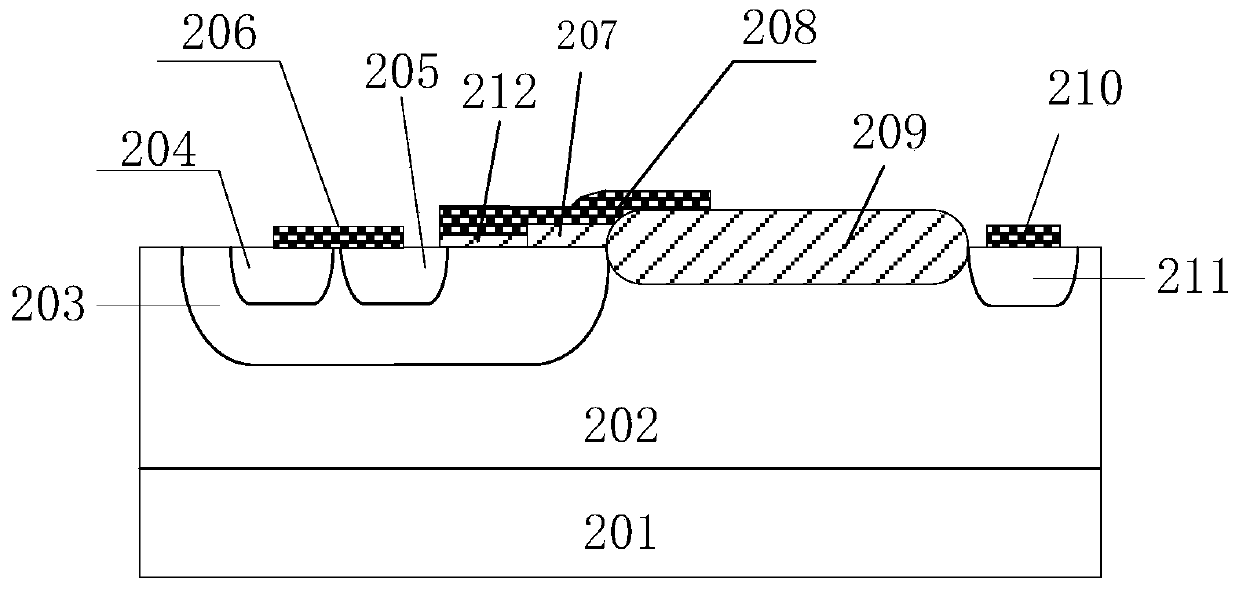

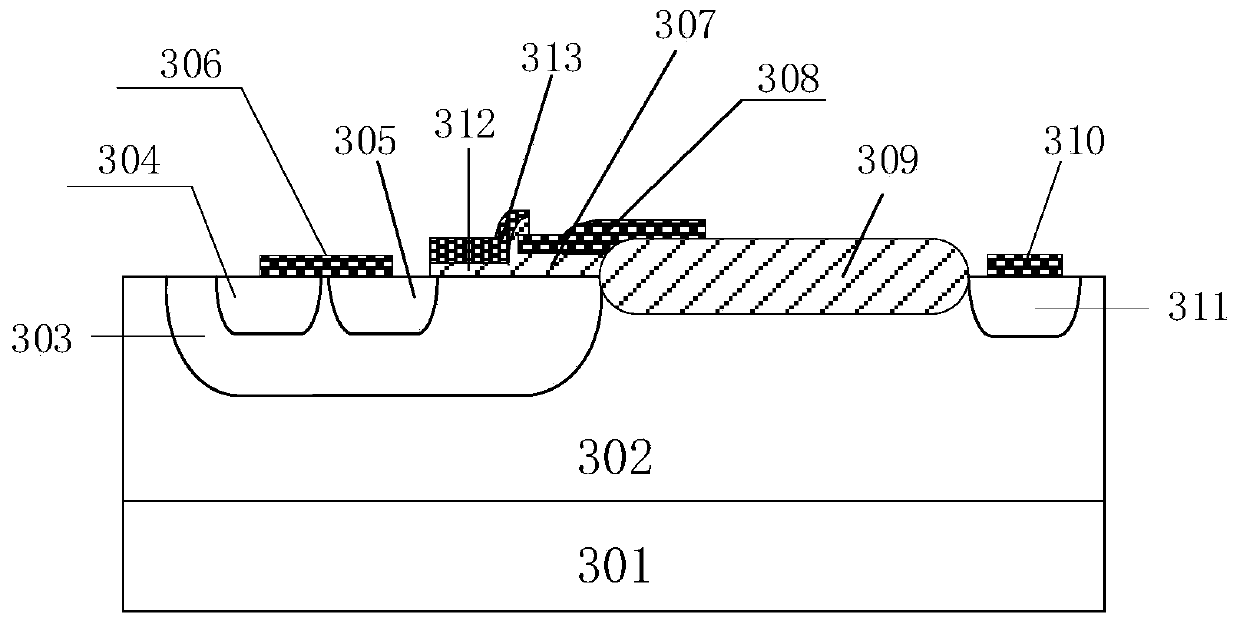

[0027] The present invention proposes a LDMOS device structure with total dose effect hardening capability, and its specific structure is as follows figure 2 with image 3 shown. figure 2 The device shown has a thin gate oxide (212) and a thick gate oxide (207). The amount of transistor threshold voltage shift induced by total dose radiation is generally proportional to the square of the thickness of the gate oxide, so the thinner gate oxide The threshold voltage shift caused by the total dose effect is relatively small. image 3 The device can be regarded as a double gate oxide device including a thin oxide layer gate (313) and a thick oxide layer gate (308). Applying an appropriate voltage to the two gates can turn on the device, but when any one of the devices is turned on alone The LDMOS is not turned on.

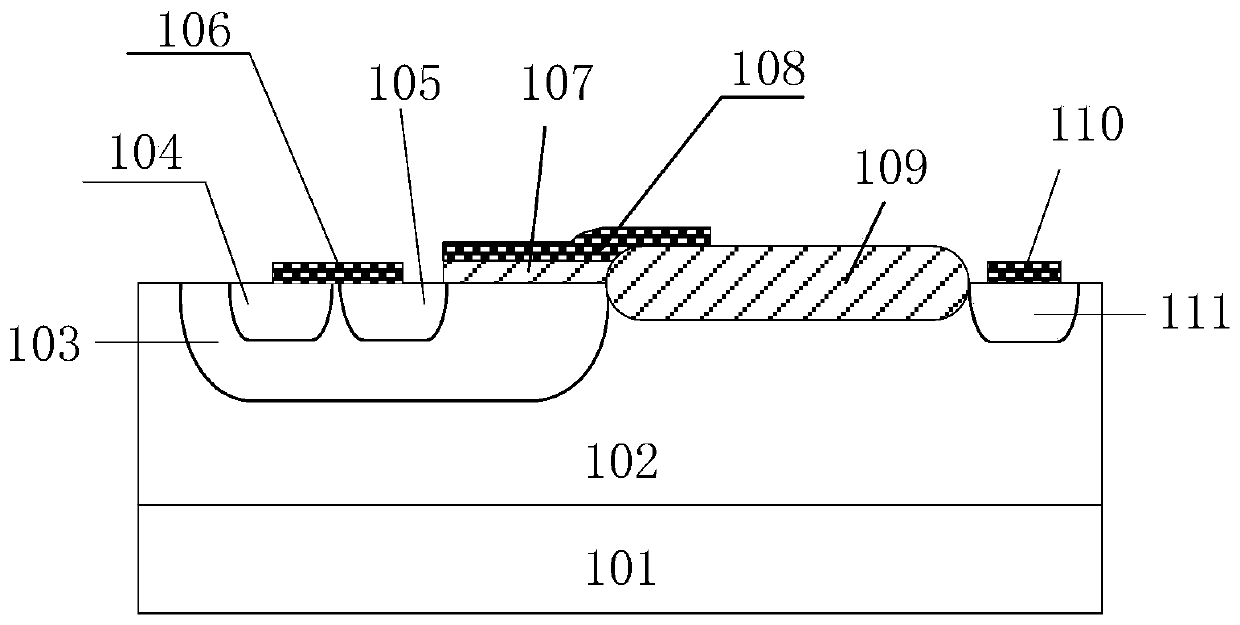

[0028] when figure 1 When the device shown is subjected to total dose effect radiation, the thickness of its gate oxide layer (107) is much greater than that of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com