CoO/NPC@SnO2 bifunctional catalyst obtained by employing metal organic frame and preparation method thereof

A technology of metal-organic frameworks and nano-catalysts, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of impact, low operating temperature, and poor durability of Pt-based catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

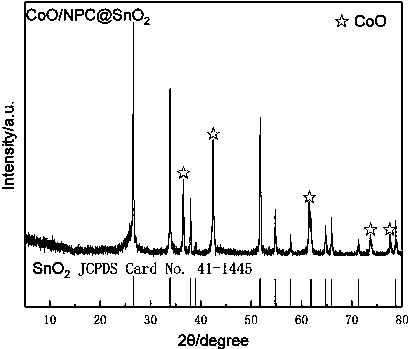

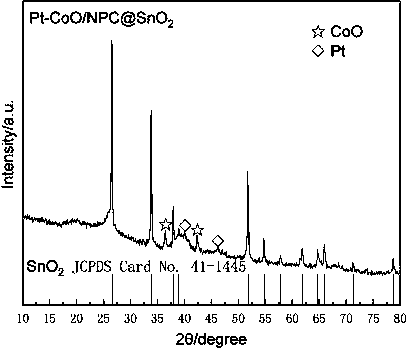

[0022] Specific implementation method 1: rhombohedral core-shell structure CoO / NPC@SnO 2 The preparation method of composite nano catalyst is as follows:

[0023] 1. Dissolve the soluble cobalt salt and 2-methylimidazole in 25mL of methanol respectively. After fully ultrasonicating and stirring, quickly pour the methanol solution of 2-methylimidazole into the methanol solution of the soluble cobalt salt, continue stirring, and then statically Placed, washed with methanol by centrifugation, and dried to obtain purple MOFs;

[0024] 2. Put the MOFs prepared in step 1 into a tube-type resistance furnace, heat-treat in an inert gas protective atmosphere, and after natural cooling, take out the samples and wash them with acid and deionized water for several times to obtain Co / NPCs;

[0025] 3. Take the sample from step 2 and stir it with tin salt in methanol, then add sodium borohydride to the above mixed solution to prepare Co / NPC@Sn;

[0026] 4. Take the sample obtained in st...

Embodiment approach 2

[0028] Specific implementation method two: the difference between this implementation method and the specific implementation method one is that the selected soluble cobalt salt in step one is Co(NO 3 ) 2 ·6H 2 0, ultrasonic and stirring time are 20min, other is identical with specific embodiment one;

Embodiment approach 3

[0029] Specific implementation method three: the difference between this implementation mode and specific implementation mode one or mode two is that in step two, nitrogen is selected as the inert gas, the heat treatment temperature is 700 ° C, and the maintenance time is 2 hours; Or the same as the second method;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com