Solar thermal membrane distillation device

A technology of distillation device and photothermal film, which is applied in general water supply saving, water/sludge/sewage treatment, water/sewage treatment, etc. It can solve the problems of bulky device, high system cost and high manufacturing cost, and achieve efficient collection , avoid membrane fouling, and solve the effect of blocking light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

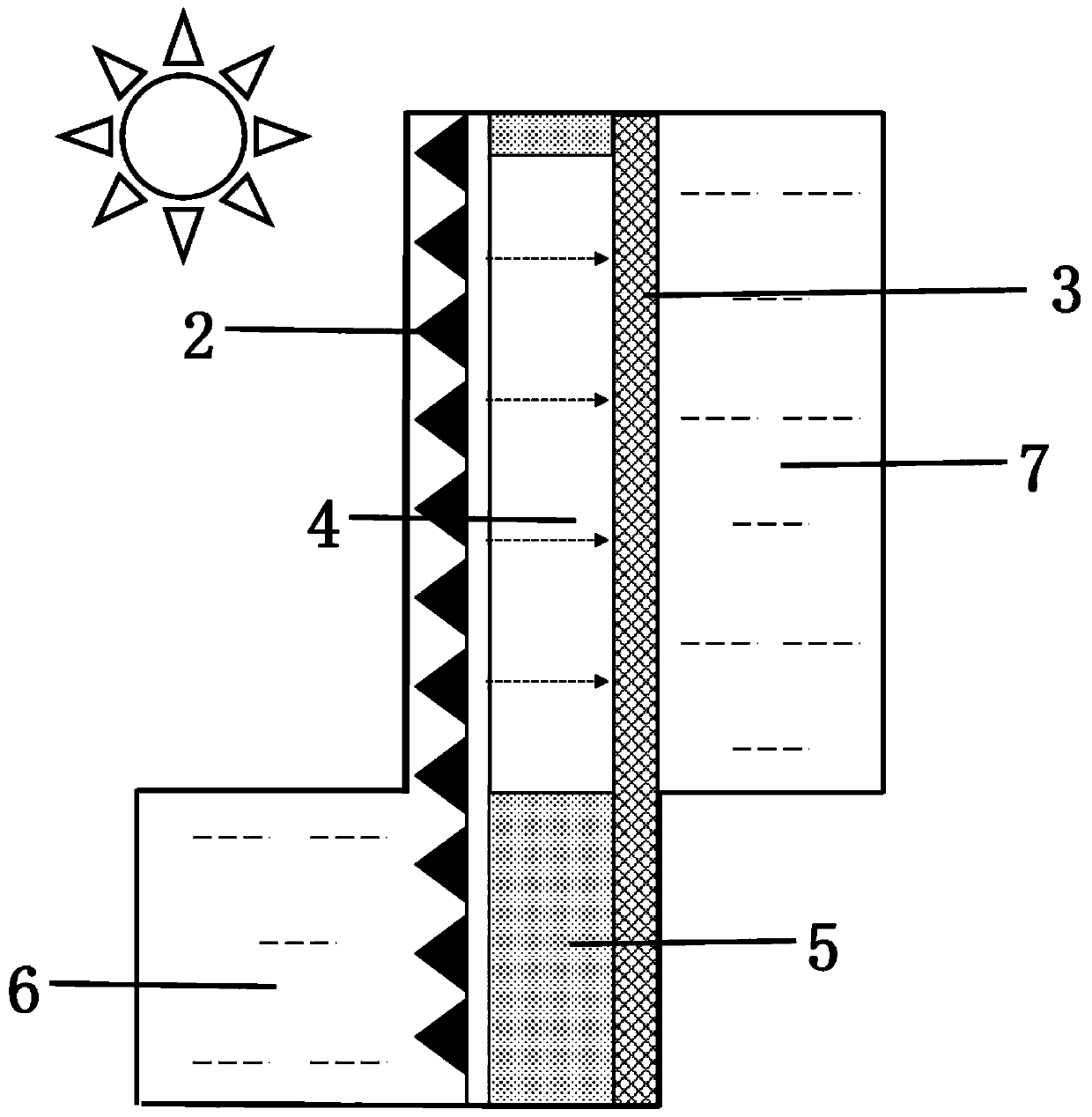

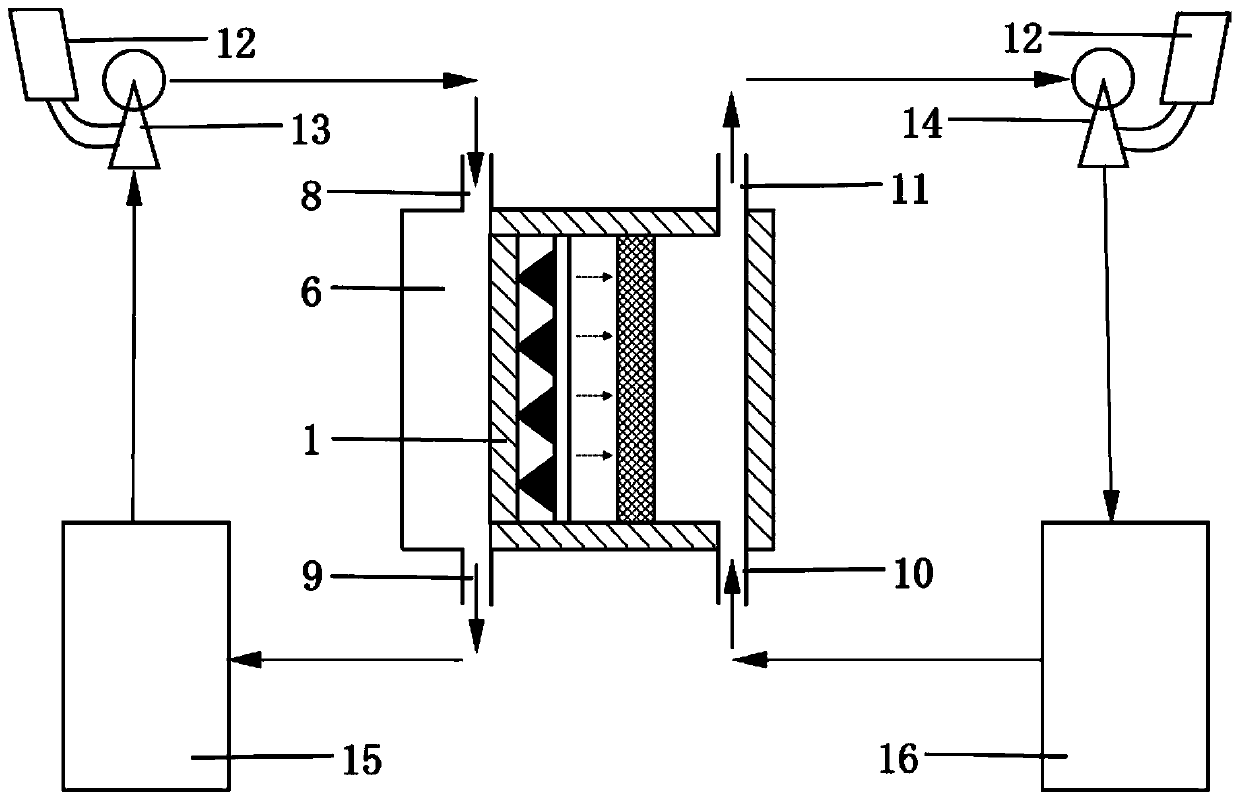

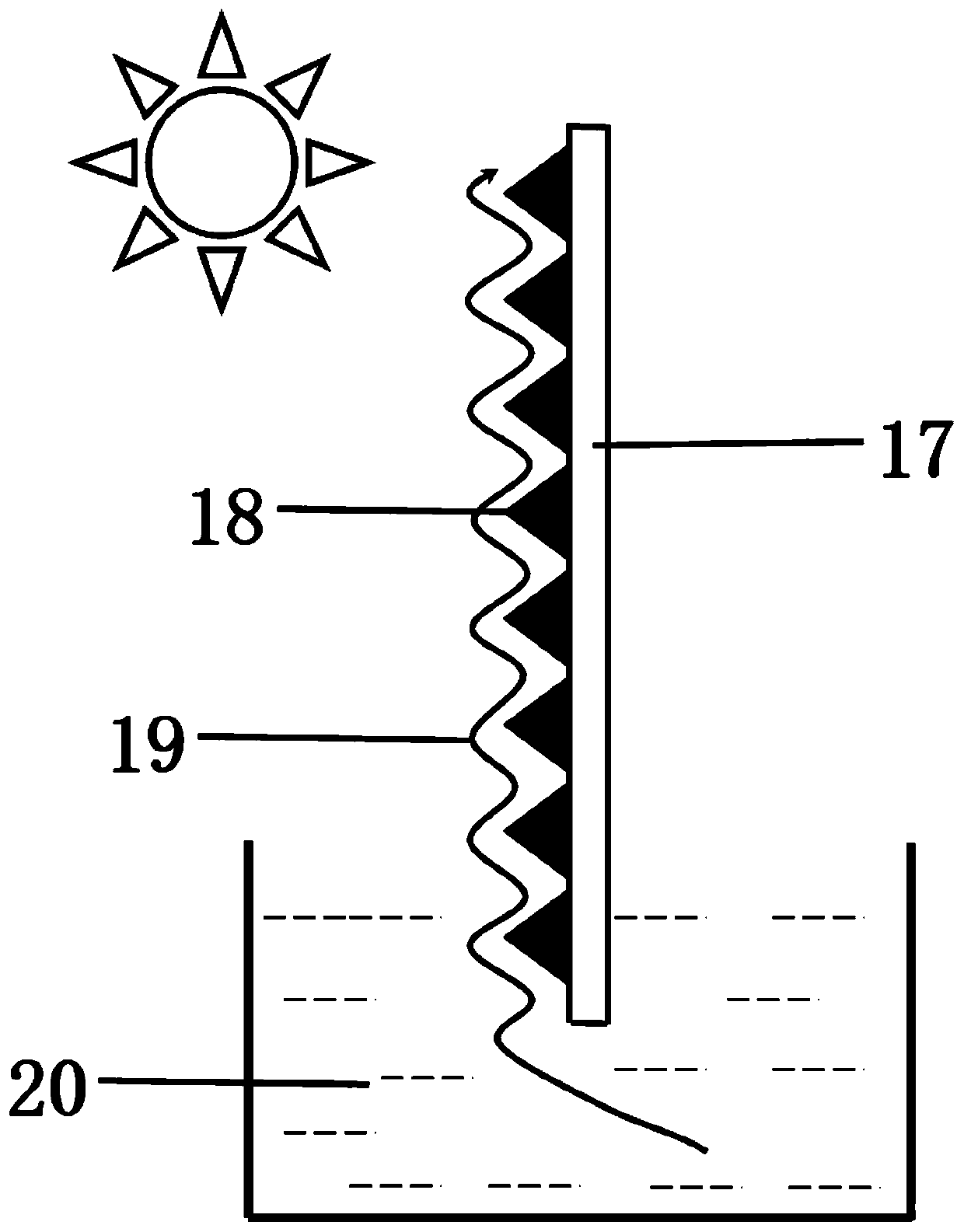

[0056] Such as figure 1 , figure 2 As shown, the solar photothermal seawater desalination device provided by the present invention includes: a transparent glass plate 1, an independent photothermal evaporation material 2, a hydrophobic film 3, a water vapor channel 4, a spacer 5, a water supply tank 6, and a cold liquid tank 7. Raw water inlet 8, concentrated water outlet 9, condensed water inlet 10, condensed water outlet 11, solar battery 12, feed water pump 13, condensed water pump 14, feed water storage tank 15, condensed water storage tank 16. Wherein, the transparent glass plate 1 and the water supply tank 6 form a water supply chamber, the upper part of the water supply chamber is provided with a raw water inlet 8, and the lower part of the water supply chamber is provided with a concentrated water outlet 9. The independent photothermal evaporation material 2, the hydrophobic film 3, the water vapor channel 4 and the spacer 5 form an evaporation chamber. The lower pa...

Embodiment 2

[0073] The solar photothermal film distillation device used in this embodiment is as described in Example 1, wherein the pore diameter of the hydrophobic film 3 is 0.1 μm; the width of the water vapor channel 4 is 3 mm; the preparation method of the independent photothermal evaporation material 2 is as follows:

[0074] 1. Place nickel foam in the plasma-enhanced chemical vapor deposition reaction chamber, evacuate to <10Pa, and then heat to 700°C;

[0075] 2. Open CH 4 with H 2 Air valve, into CH 4 with H 2 mixed gas, where H 2 The flow rate is 5ml min -1 , CH 4 The flow rate is 5ml min -1 , adjust the air pressure to 50Pa;

[0076] 3. Turn on the inductively coupled plasma source, adjust the power to 250W, and maintain it for 60 minutes;

[0077] 4. Turn off the plasma source, turn off the CH 4 with H 2 Gas valve, open the Ar gas valve, pass into Ar as cooling gas, wait to be cooled to room temperature, take out the vertically oriented graphene / graphene foam;

[0...

Embodiment 3

[0081] The solar photothermal film distillation device used in this embodiment is as described in Example 1, wherein the pore diameter of the hydrophobic film 3 is 0.2 μm; the width of the water vapor channel 4 is 2 mm; the preparation method of the independent photothermal evaporation material 2 is as follows:

[0082] 1. Place nickel foam in the plasma-enhanced chemical vapor deposition reaction chamber, evacuate to <10Pa, and then heat to 650°C;

[0083] 2. Open CH 4 with H 2 Air valve, into CH 4 with H 2 mixed gas, where H 2 The flow rate is 5ml min -1 , CH 4 The flow rate is 5ml min -1 , adjust the air pressure to 400Pa;

[0084] 3. Turn on the inductively coupled plasma source, adjust the power to 250W, and maintain it for 30 minutes;

[0085] 4. Turn off the plasma source, turn off the CH 4 with H 2 Gas valve, open the Ar gas valve, pass into Ar as cooling gas, wait to be cooled to room temperature, take out the vertically oriented graphene / graphene foam;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com