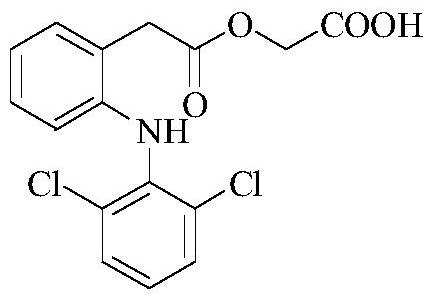

A kind of preparation method of aceclofenac

A technology for butaclofenac and compounds is applied in the preparation of organic compounds, cyanide reaction preparation, chemical instruments and methods, etc., can solve the problems of slow heating process, uneven heating and the like, and achieves easy product and less diclofenac content. , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

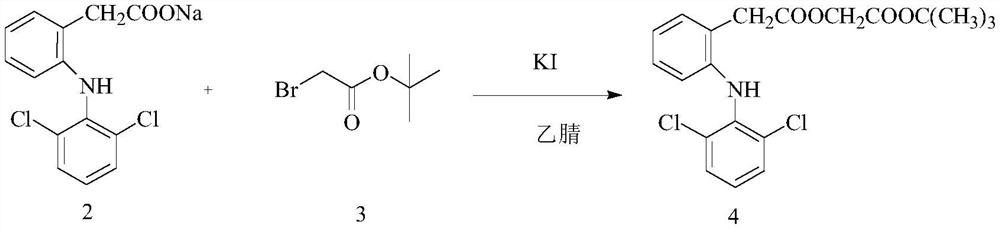

[0027] Example 1: Preparation of 2-((2,6-dichlorophenyl)amino)phenylacetoxyacetic acid tert-butyl ester (aceclofenac tert-butyl ester)

[0028]

[0029] Diclofenac sodium (10 g, 33.8 mmol), tert-butyl bromoacetate (7.85 g, 40.3 mmol), KI (0.26 g, 1.6 mmol), acetonitrile (30 mL) were added to a 100 mL flask. Microwave conditions were set, the power was 100W, the temperature was 30°C, and the reaction time was 15min. After the reaction was completed, the reaction solution was poured into 100 mL of purified water and stirred for 2 h for crystallization. After suction filtration, the filter cake was washed twice with 100 mL of purified water to obtain a crude product of aceclofenac tert-butyl ester.

[0030] The crude product and ethanol (280 mL) were added to a 500 mL three-necked flask, heated to 75°C, until the solid was completely dissolved, stirred and cooled to 10°C for crystallization for 2 h, suction filtered, and the filter cake was washed twice with 100 mL of ethanol...

Embodiment 2

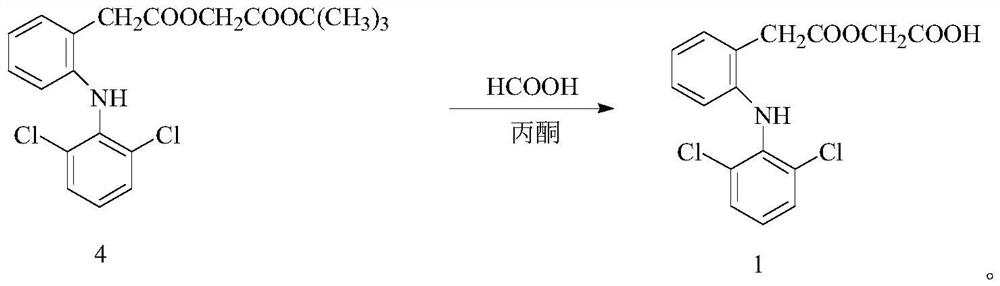

[0031] Example 2: Preparation of Aceclofenac

[0032]

[0033] Aceclofenac tert-butyl ester (7.0 g, 17.1 mmol), formic acid (14 mL, 371.3 mmol) and acetone (3.5 mL) were added to a 50 mL three-necked flask. Microwave conditions were set, the power was 200W, the temperature was 65°C, and the reaction time was 10min. After the reaction was completed, the reaction solution was slowly poured into 80 mL of purified water, stirred for 10 minutes, filtered with suction, and the filter cake was washed twice with 20 mL of purified water to obtain a crude product. The crude product was dissolved in toluene (12 mL), and the temperature was raised to 90 °C. After the solid was completely dissolved, the temperature was stirred and cooled to 10 °C for crystallization, and the crystals were grown for 2 h. g, the yield is 96.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com