Low-rank coal high-temperature pyrolysis process combined with iron and steel industry

A high-temperature pyrolysis and low-rank coal technology, applied in the field of coal chemical industry, can solve the problems of high energy consumption, long time, and high concentration of harmful substances, and achieve the effect of low energy consumption and short heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

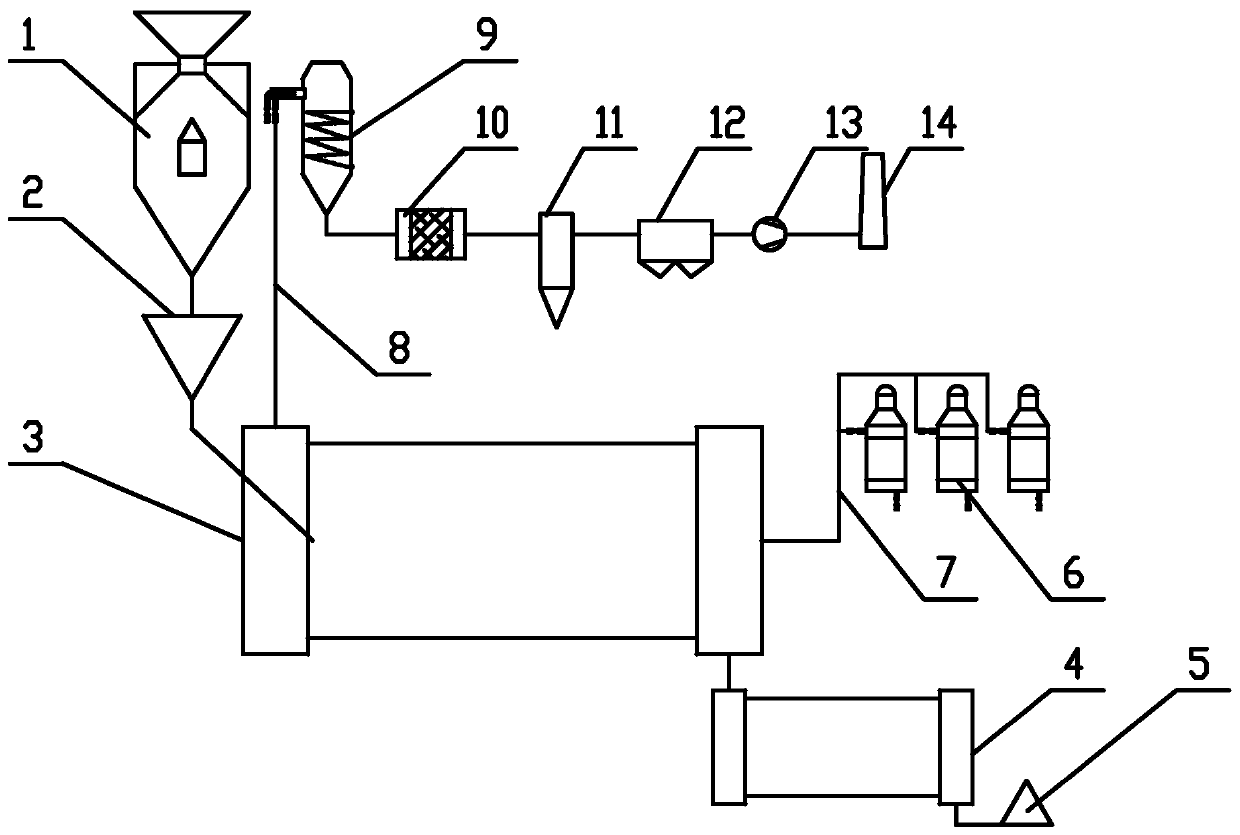

[0017] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

[0018] The basic idea of the present invention is to build a production workshop inside the iron and steel plant, use low-rank coal as raw material, use blast furnace gas as fuel, adopt a low-pollution, energy-saving high-temperature pyrolysis process, and produce solid products instead of coke for sintering. Include the following steps:

[0019] (1) Low-rank coal is used as raw material, after being dried by drying furnace 1, it enters coal storage bin 2, and then enters rotary kiln 3, which is a non-oxidizing high-temperature rotary kiln, and the furnace does not contain oxygen to ensure that the blast furnace gas Will not react with oxygen at high temperature;

[0020] (2) The blast furnace gas produced by the blast furnace is used as fuel, heated to above 1050°C by the regenerative hot gas furnace 6, and then introduced into the rotary furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com